Fast handling system for vegetable planting shed

The technology of a handling system and a planting shed is applied in the field of rapid handling systems for vegetable planting sheds, which can solve the problems of easily injured workers' knee joints, low efficiency, heavy weight, etc., so as to reduce labor intensity, improve planting efficiency, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

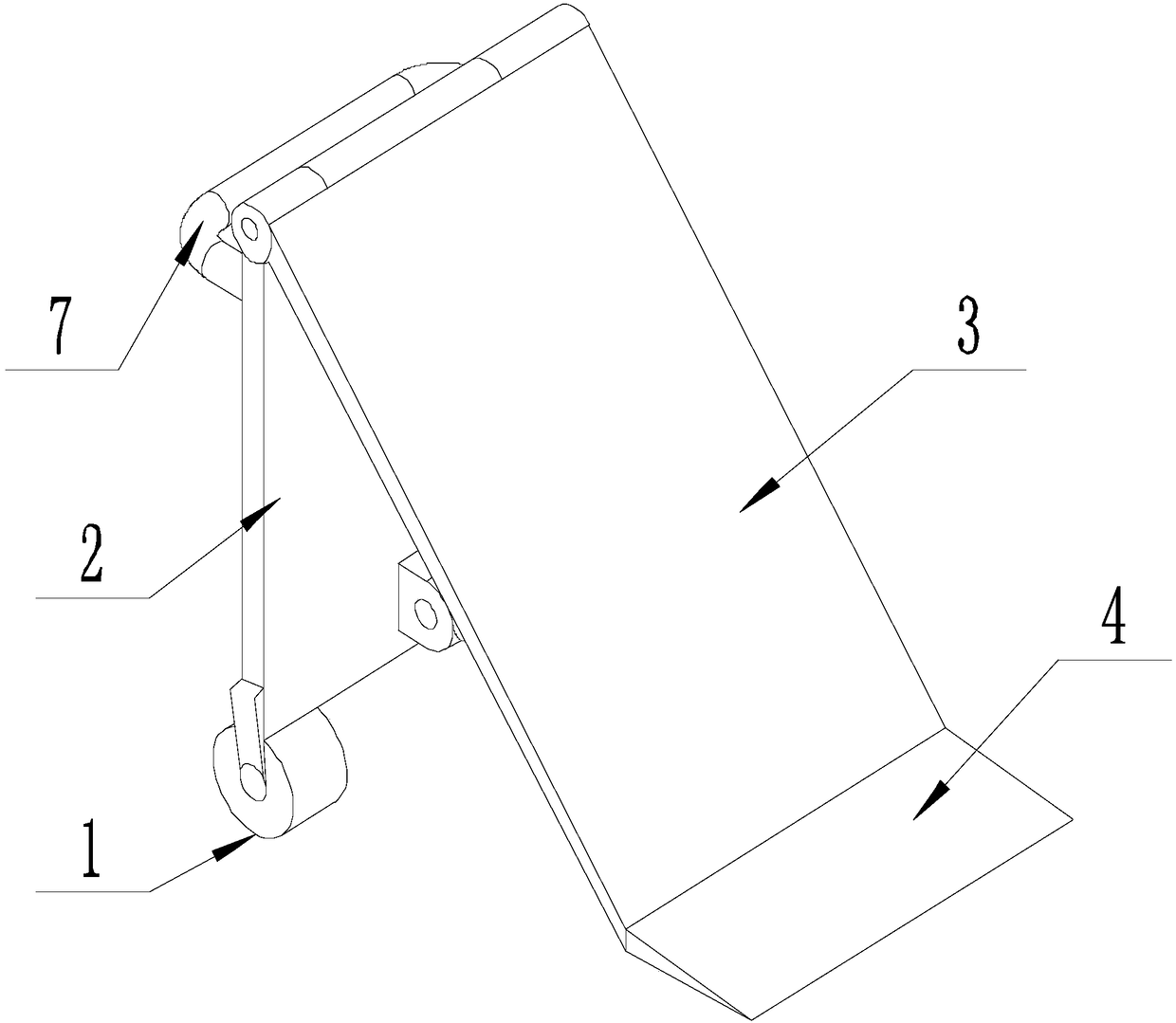

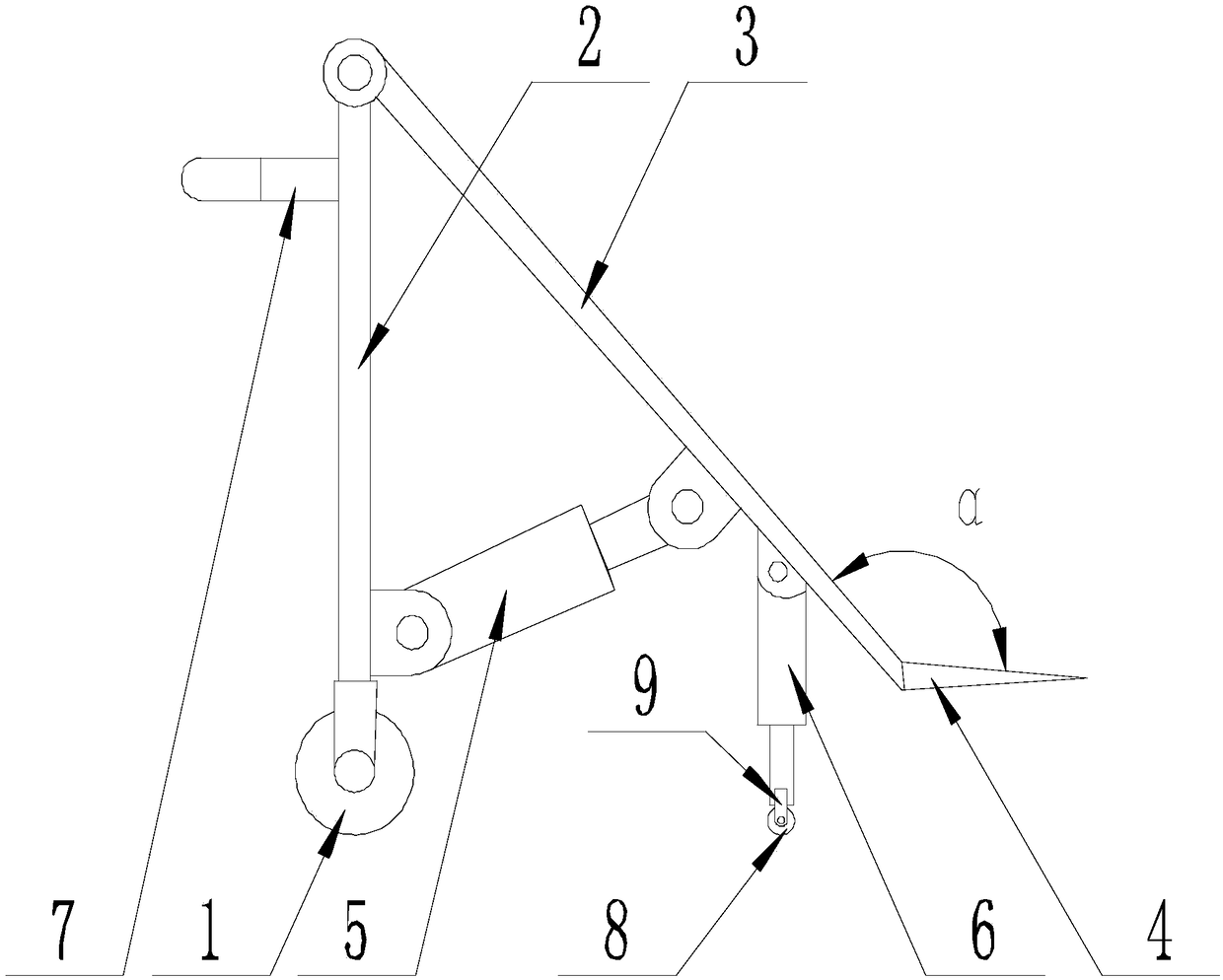

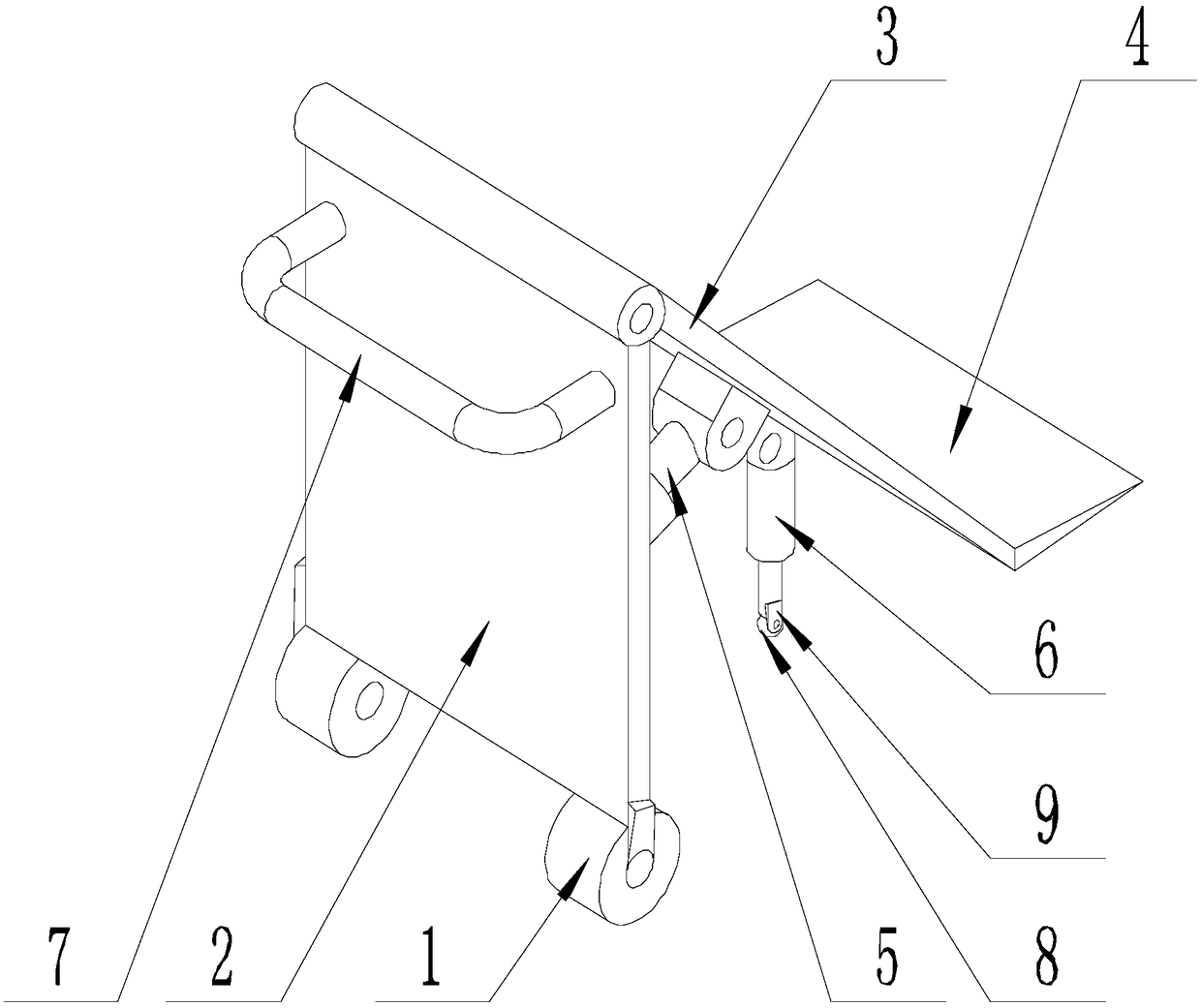

[0036] Such as Figure 1-Figure 3 As shown, the rapid handling system for vegetable planting sheds of the present invention includes a roller 1, a support plate 2, a rotating plate 3 and a pick-up plate 4 connected in sequence, and one end of the support plate 2 close to the ground is connected with the roller 1, and the The roller 1 can rotate around its own axis, and the axis of the roller 1 is parallel to the support plate 2. The other end of the support plate 2 is hinged to the rotating plate 3. The axis of the hinge is parallel to the axis of the roller 1. One end is connected with an end of the material taking plate 4;

[0037] On the surface of the rotating plate 3 close to the support plate 2, there is a telescopic device I6, one end of the telescopic device I6 is hinged to the support plate 2, the other end of the telescopic device I6 is in contact with the ground, and the telescopic axis of the telescopic device I6 is vertical on the ground.

[0038] When carrying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com