A kind of extraction machine for curly tea

A technology of milling machine and curly shape, which is applied in the field of milling machine for curly tea, which can solve the problems of blackening of finished tea, unreported progress, high labor intensity, etc., to improve the degree of automation of operations, and to implement simple and convenient , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

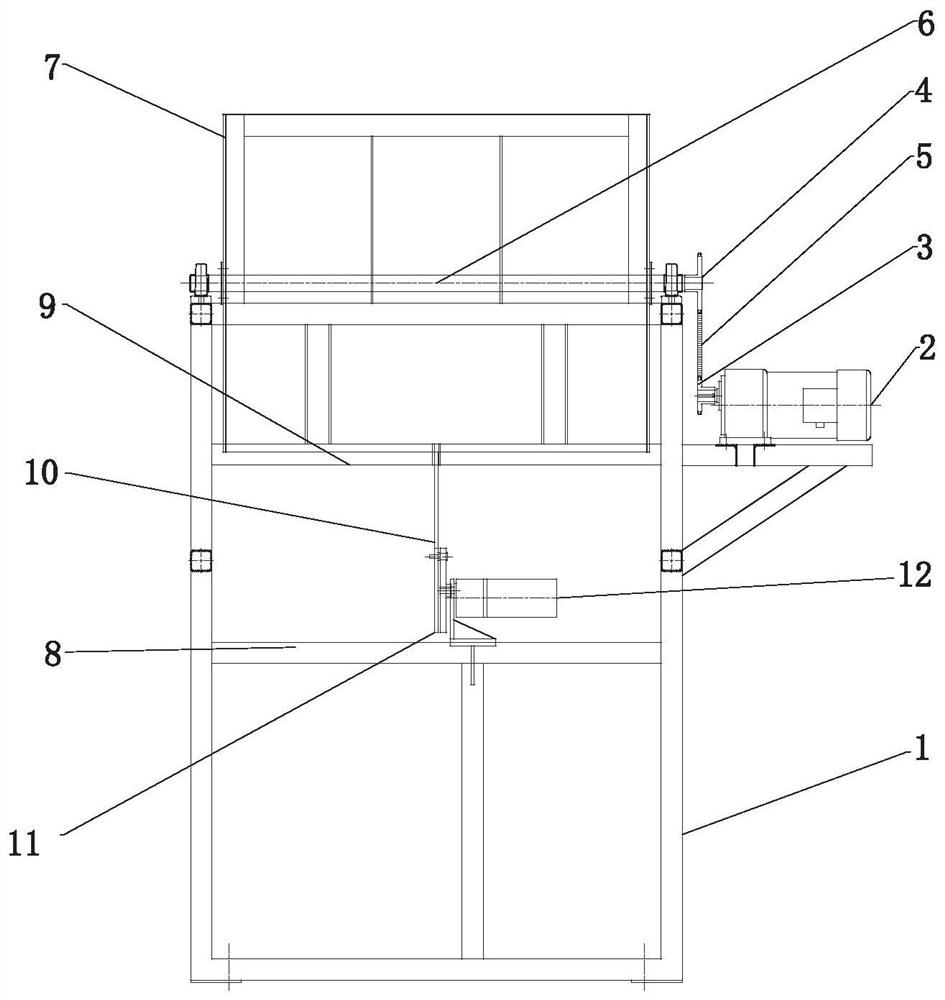

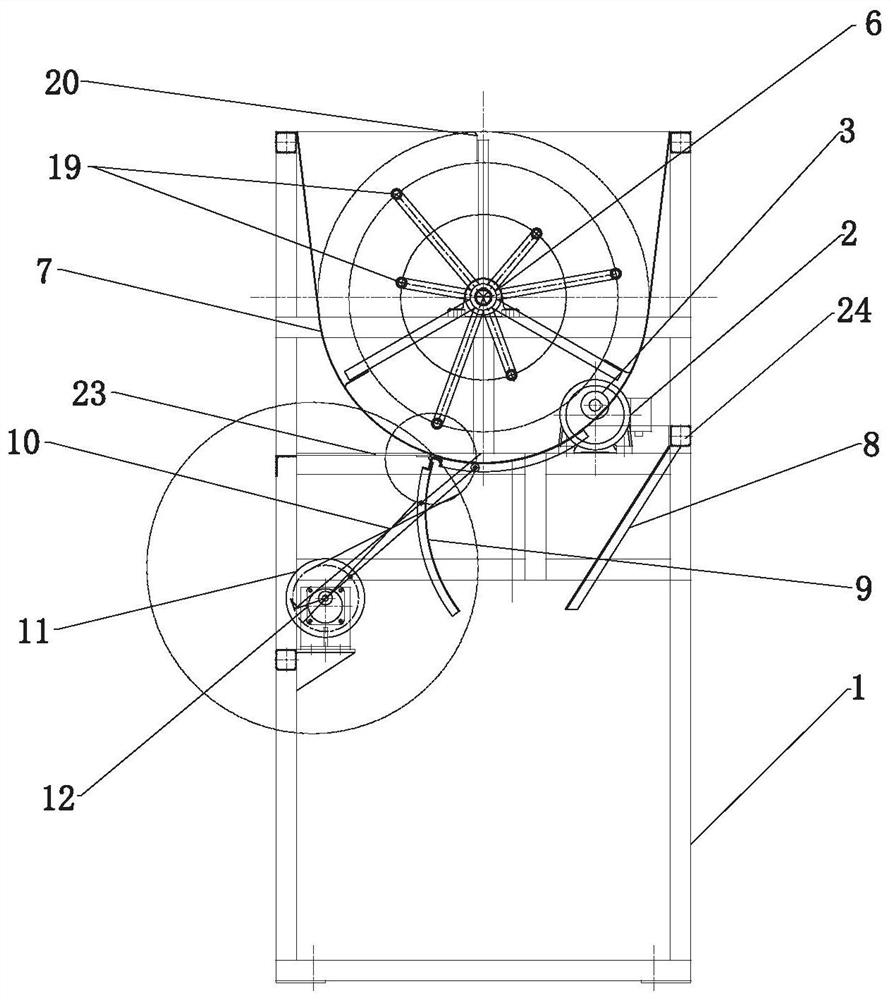

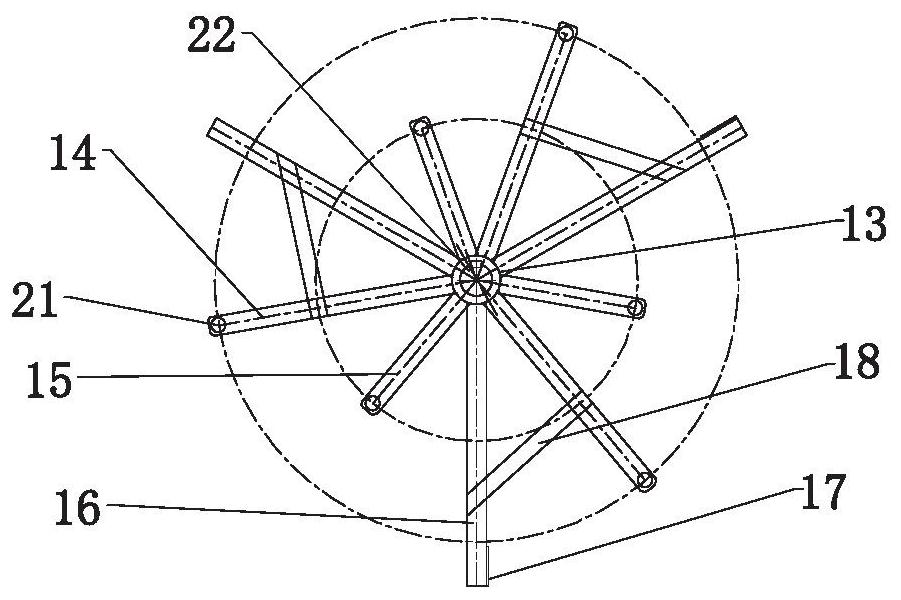

[0023] Such as Figure 1 to Figure 3 As shown, a milli-lifting machine for curled tea includes a frame assembly 1, a main motor 2, a main shaft assembly 6 and a milli-lifting pot assembly 7, a main motor 2, a main shaft assembly 6 and a milling pot The assembly 7 is installed on the frame assembly 1. Lifting pot assembly 7 includes a lifting pot body, an end plate and a heating plate. The lifting pot body is made of a stainless steel plate. Bucket-type pot, the heating plate is attached to the outer surface of the pot body. The central shaft 22 of the main shaft assembly 6 is suspended directly above the pot body and is connected with the main motor 2 in transmission. The frame assembly 1 includes the frame and the lifting pot fixing beam welded on the frame, the lifting pot supporting plate, the main motor bracket, the door opening motor bracket, the hatch hinge mounting plate 23, the tea plate bracket 24 and the bearing seat , the frame is welded by the bottom plate, beam...

Embodiment 2

[0030] Carrying cents roller 19 two ends is provided with prominent rotating shaft, and described cents carrying roller support rod free end is provided with axle hole, and cents carrying roller 19 is inserted in the axle hole by rotating shaft rotation. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com