Double-station aluminum alloy profile aligning device

An aluminum alloy profile and double-station technology, which is applied in the field of double-station aluminum alloy profile alignment devices, can solve the problems of product internal structure or surface damage, time-consuming and labor-intensive, and achieve simple and reasonable structural design, avoid damage, and protect the appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

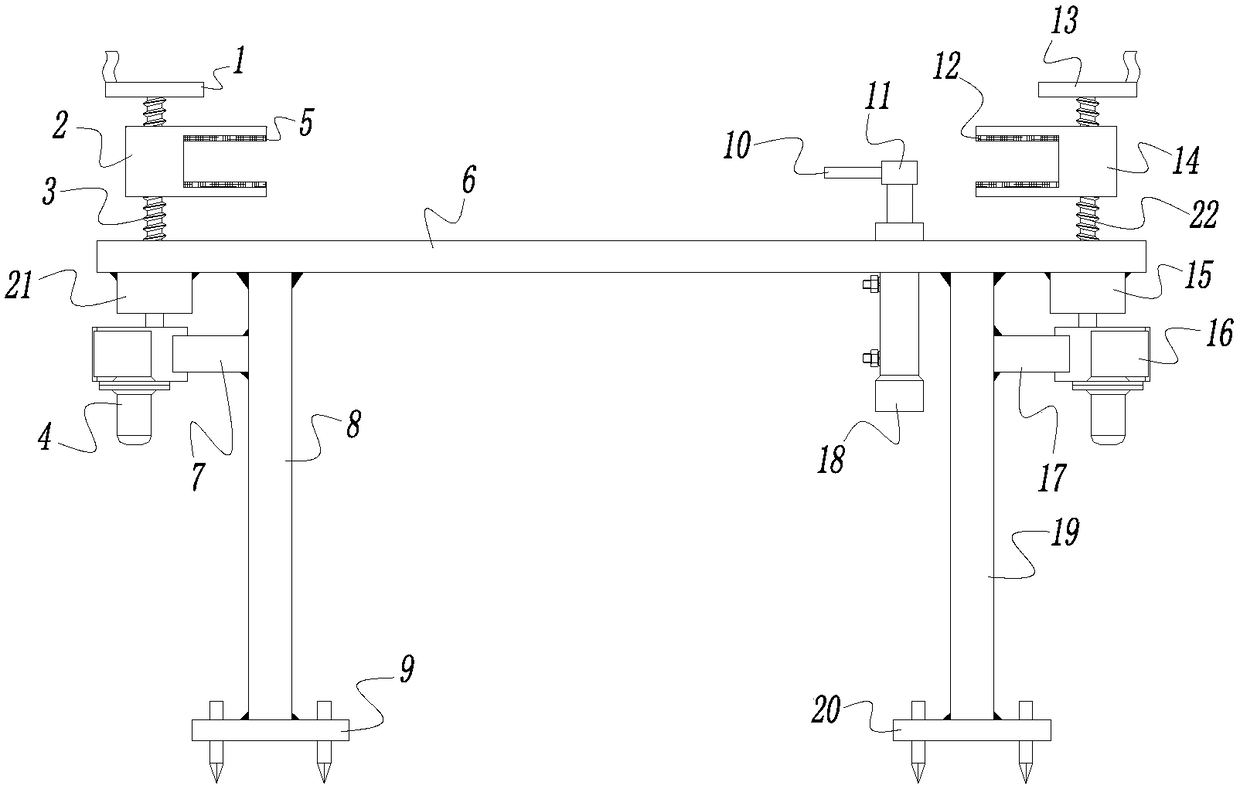

[0012] See figure 1 , the dual-station aluminum alloy profile aligning device of the present invention includes a first column 8 with a first foot 9 at the lower end and a second column 19 with a second foot 20 at the lower end, between the first column 8 and the second The tops of both columns 19 are provided with beams 6 . In this embodiment, both the first anchor 8 and the second anchor 19 are fixedly connected to the ground with anchors.

[0013] A first fixing device is installed and fixed on the left end of the beam 6, and a second fixing device is installed and fixed on the right end.

[0014] The first fixing device includes a first bearing seat 21 fixed with the crossbeam 6 and has a first bearing, and also includes a first lead screw 3 with a first handwheel 1 installed on the upper end, and a fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap