Clamping tool for drilling of end cover of wind turbine generator shell

A wind turbine, clamping tooling technology, applied in the direction of clamping, positioning device, manufacturing tool, etc., can solve the problems of difficult batch processing, low processing efficiency, etc., to achieve convenient clamping, simple structure, and easy batch processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

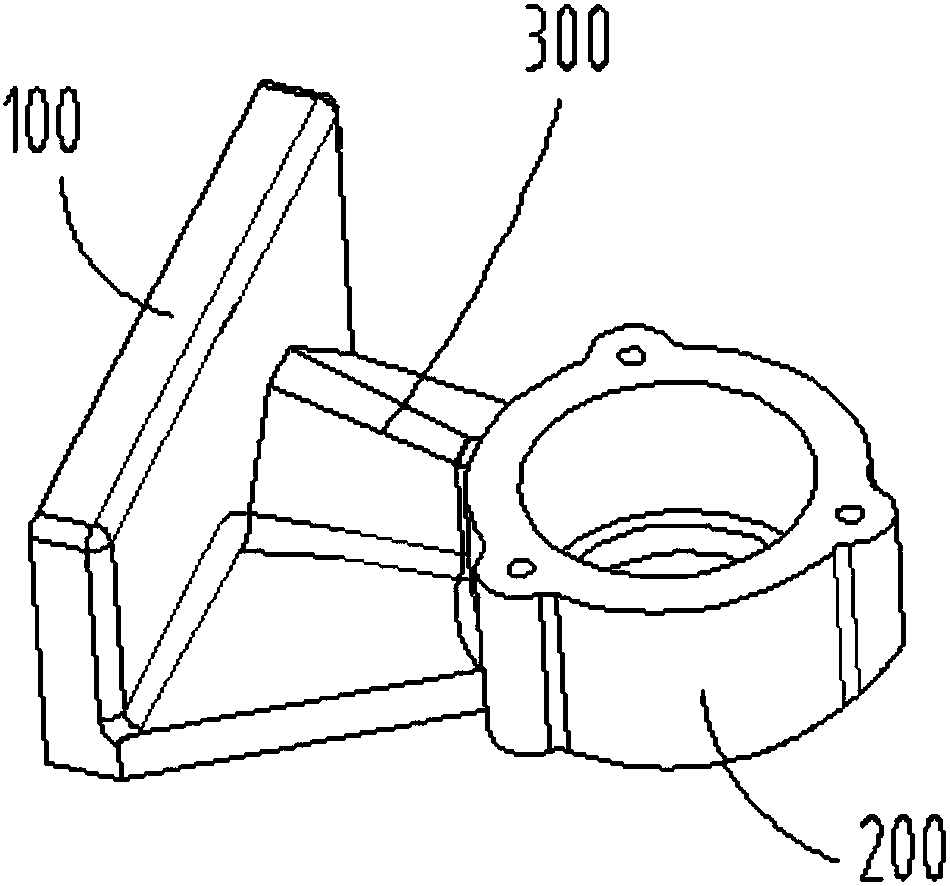

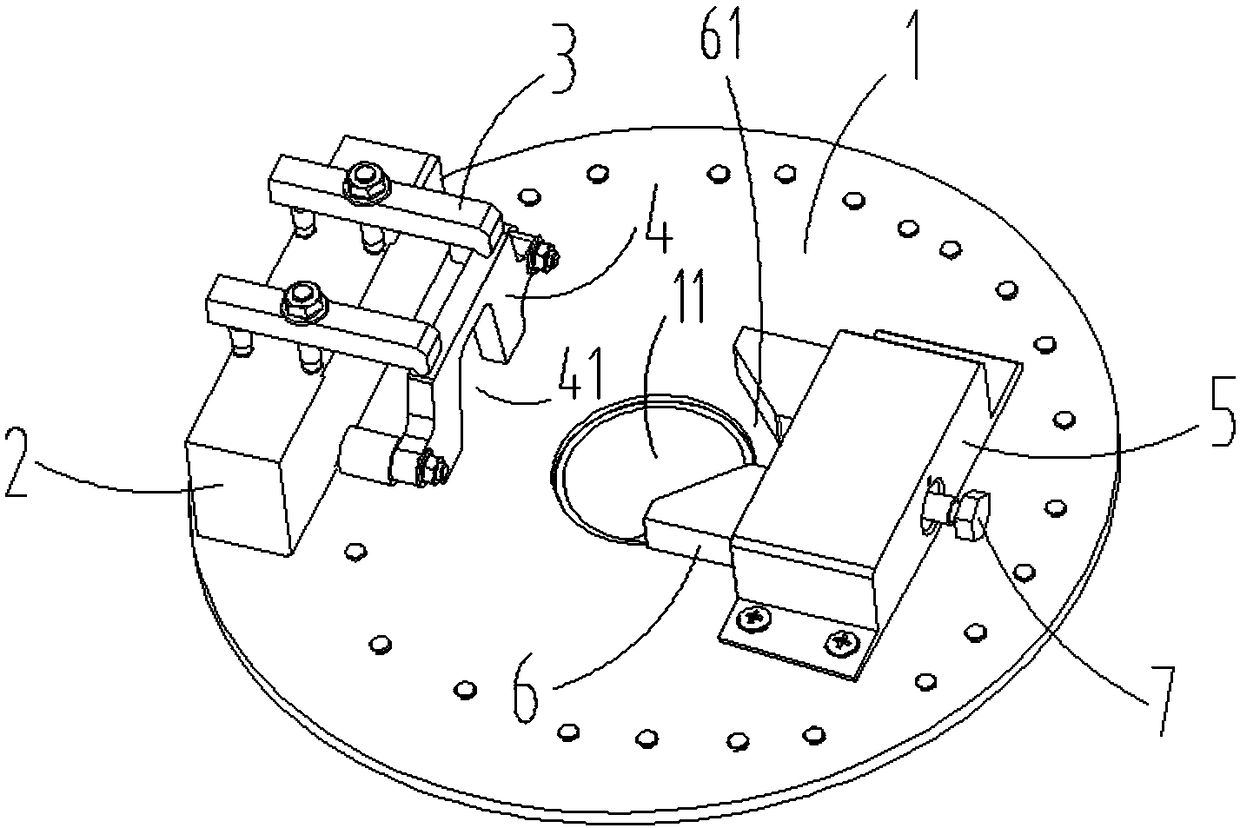

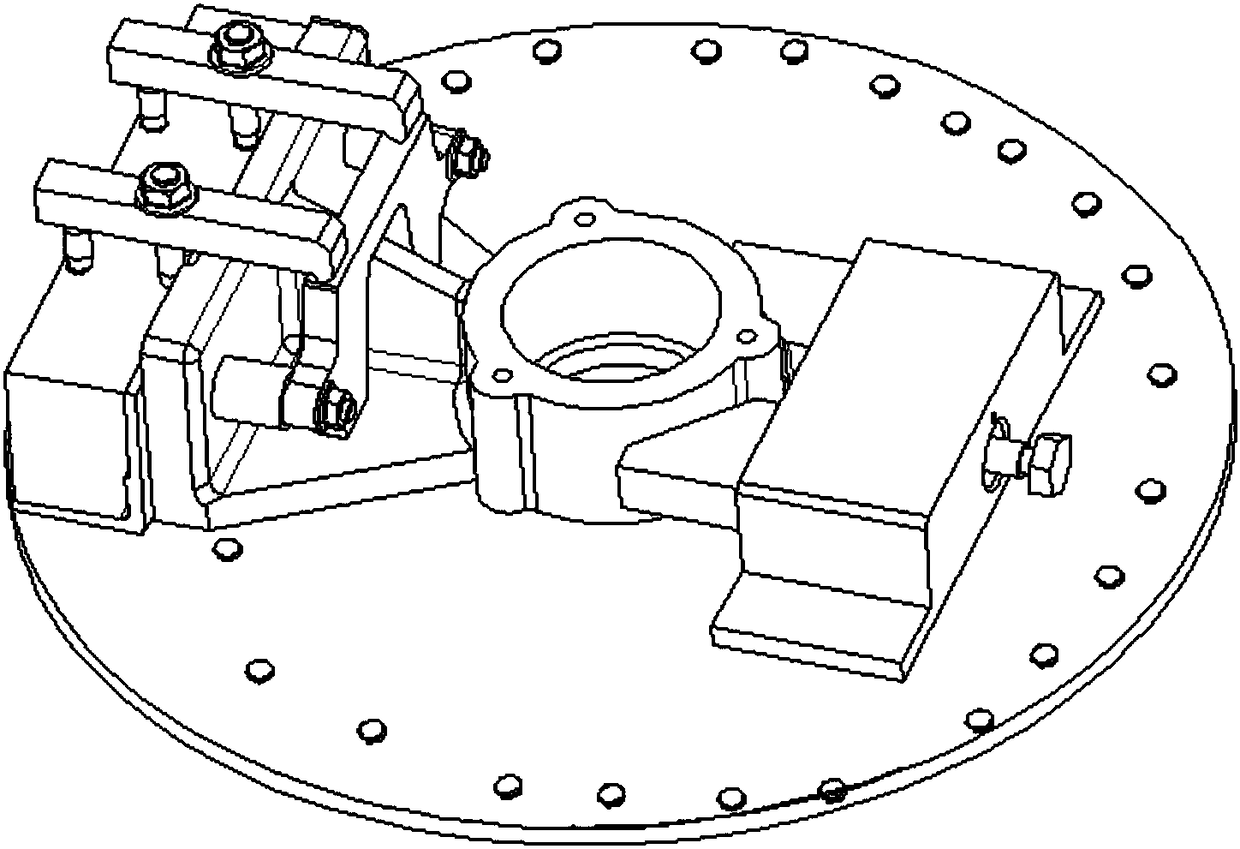

[0014] Such as figure 2 and image 3 , the invention discloses a clamping tool for drilling the end cover of the wind power generator casing, including a chassis 1, a mounting block 2, a mounting rod 3, a fixing block 4, a mounting seat 5, a locking block 6 and a locking screw 7. The chassis 1 has a circular structure, the mounting block 2 and the mounting seat 5 are fixedly connected to the upper end surface of the chassis 1, and the two mounting rods 3 are fixedly connected to the upper end surface of the mounting block 2 through screws parallel to each other. The fixed block The two ends of 4 are fixedly connected with two mounting rods 3 respectively. The locking block 6 is inserted into the mounting seat 5 along the radial direction of the chassis 1 , the locking screw 7 is screwed on the mounting seat 5 , and one end of the locking screw 7 is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com