Manufacturing method of ultra-fine special-shaped spinneret holes

A manufacturing method and spinneret technology, which is applied in the direction of spinneret assembly, filament/thread forming, textile and papermaking, etc., can solve the problems such as difficult to achieve ultra-fine special-shaped nozzles, and achieve easy batch processing and high precision The effect of high height and various structural forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] (7) Preparation of the etching mask for the special-shaped hole of the spinneret: on the silk outlet surface layer of the integrated structure, the UV-LIGA technology is used to carry out the second photolithography, including the glue rejection, exposure, and development carried out in sequence Processing, to realize the patterning of the special-shaped spinneret hole mask, and with the help of double-sided photolithography technology, to realize the alignment of the two photolithography, that is, to realize the alignment of the special-shaped spinneret hole and the guide hole to be processed.

[0051] In some embodiments, the "by means of double-sided lithography technology" refers to: loading the first photoresist plate and the second photoresist plate containing alignment marks into the upper and lower plate positions of the lithography machine respectively , placing the opaque integrated structure between the first photoresist and the second photoresist, using doubl...

Embodiment 1

[0059] Embodiment 1: This embodiment is implemented under the following conditions of implementation and technical requirements:

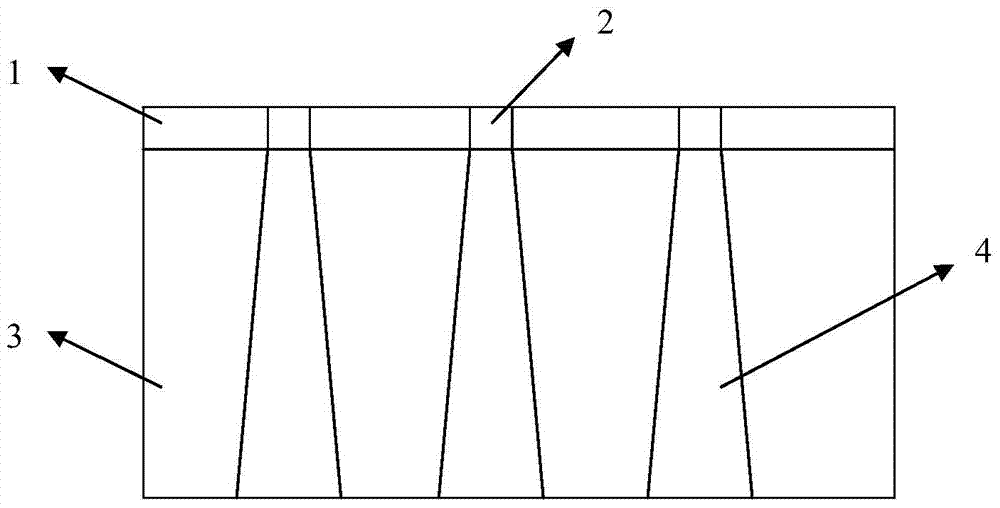

[0060] (1) Design photolithography layout: design the shape and layout layout of the spinneret guide hole 4, i.e. the mask plate used for the first photolithography; design the shape and layout layout of the spinneret capillary hole 2, namely The mask used in the second photolithography (see figure 1 ). Among them, the shape of the special-shaped hole of the spinneret is "Y-shaped", the outer diameter of the cross section is about 5 μm, and the minimum line width is about 3 μm.

[0061] (2) Preparation of a photoresist mold for the guide hole 4 of the spinneret. On a glass substrate about 3 inches in diameter, the sputter thickness is about thin layer of metallic Ti, and at a temperature of about 65°C, at a concentration of about 2wt% NaOH and 1wt% H 2 o 2 Oxidation treatment in the mixed solution for about 3 minutes to form a uniform and den...

Embodiment 2

[0068] Embodiment 2: This embodiment is implemented under the following conditions of implementation and technical requirements:

[0069] (1) Design the photolithography layout. Design the shape and layout layout of the spinneret guide hole 4, that is, the mask plate used for the first photolithography. Design the shape and layout layout of the capillary hole 2 of the spinneret, i.e. the mask plate used for the second photolithography (refer to figure 1 ). Among them, the shape of the special-shaped hole of the spinneret is "H shape", the outer diameter of the cross section is about 10 μm, and the minimum line width is 4 μm.

[0070] (2) Spinneret guide hole photoresist mold preparation. On a glass substrate with a diameter of about 4 inches, the sputtering thickness is about Metal Ti thin layer, and at 65 °C, in 2wt% NaOH and 1wt% H 2 o 2 Oxidation treatment in the mixed solution for about 3 minutes to form a uniform and dense black titanium oxide film layer to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com