Ceramic membrane cutting equipment and cutting method thereof

A technology of cutting equipment and cutting method, applied in metal processing and other directions, can solve problems such as warping, affecting the quality processing cost of ceramic film, burr at the cut of ceramic film, etc., to avoid burr, reduce cutting cost, and improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

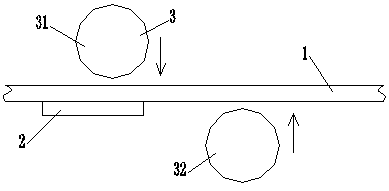

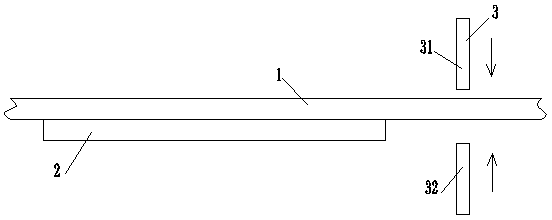

[0020] A kind of cutting equipment for ceramic film, comprises the placing frame 2 that places ceramic film 1, also comprises the cutting knife 3 that is used to cut ceramic film 1, and described cutting knife 3 comprises cutter one 31 and cutter two 32; Said cutter One 31 is on the top of the ceramic membrane 1 and cuts the ceramic membrane 1 from the top of the ceramic membrane 1; the second cutter 32 is on the bottom of the ceramic membrane 1 and cuts the ceramic membrane 1 from the bottom The ceramic membrane 1 is cut.

[0021] The second cutter 32 is at the rear of the first cutter 31 .

[0022] Note that the width of the ceramic film is L, and the distance between the first cutter 31 and the second cutter 32 is between L / 3-L.

[0023] The first cutter 31 and the second cutter 32 are rotatable circular cutters.

[0024] A lifting device is provided to drive the first cutter 31 and the second cutter 32 to move up and down.

[0025] A control device is provided to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com