Pellet mixture moisture control device and method

A technology for controlling the moisture content of a mixture, which is applied in the field of iron and steel smelting, can solve the problems of large fluctuations in the moisture content of the pellet mixture, unfavorable stable operation of the pelletizing section, and stable control of the moisture content of the pellet mixture, and achieves the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

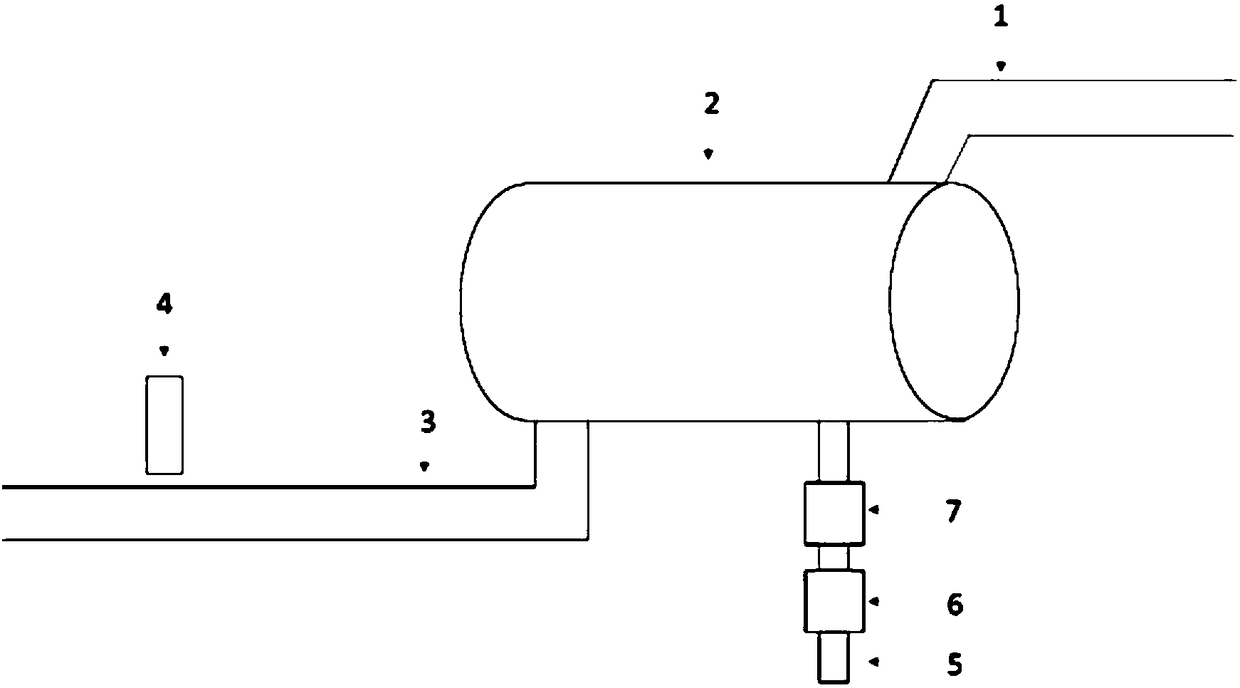

[0032] The embodiment of the present invention provides a pellet mixture moisture control device, please refer to figure 1 , the device includes:

[0033] Mixer 2.

[0034] Specifically, the mixer 2 is one of the important equipment for preparing pellets, the shape of the mixer 2 is a hollow cylinder structure, and the mixer 2 includes a feed end and a discharge end , its interior can hold the raw materials of the pellet mixture, that is, a variety of materials are mixed into a uniform mixture and sent into the mixer 2 through the feed end, and then through a series of processes, the pellets sent out from the discharge end are mixed The material can meet the production demand.

[0035] The first belt conveyor 1, the first belt conveyor 1 is arranged at one end of the mixer 2; the second belt conveyor 3, the second belt conveyor 3 is arranged at the other end of the mixer 2, wherein, the The second belt conveyor 3 is different from the first belt conveyor 1 .

[0036] Specifi...

Embodiment 2

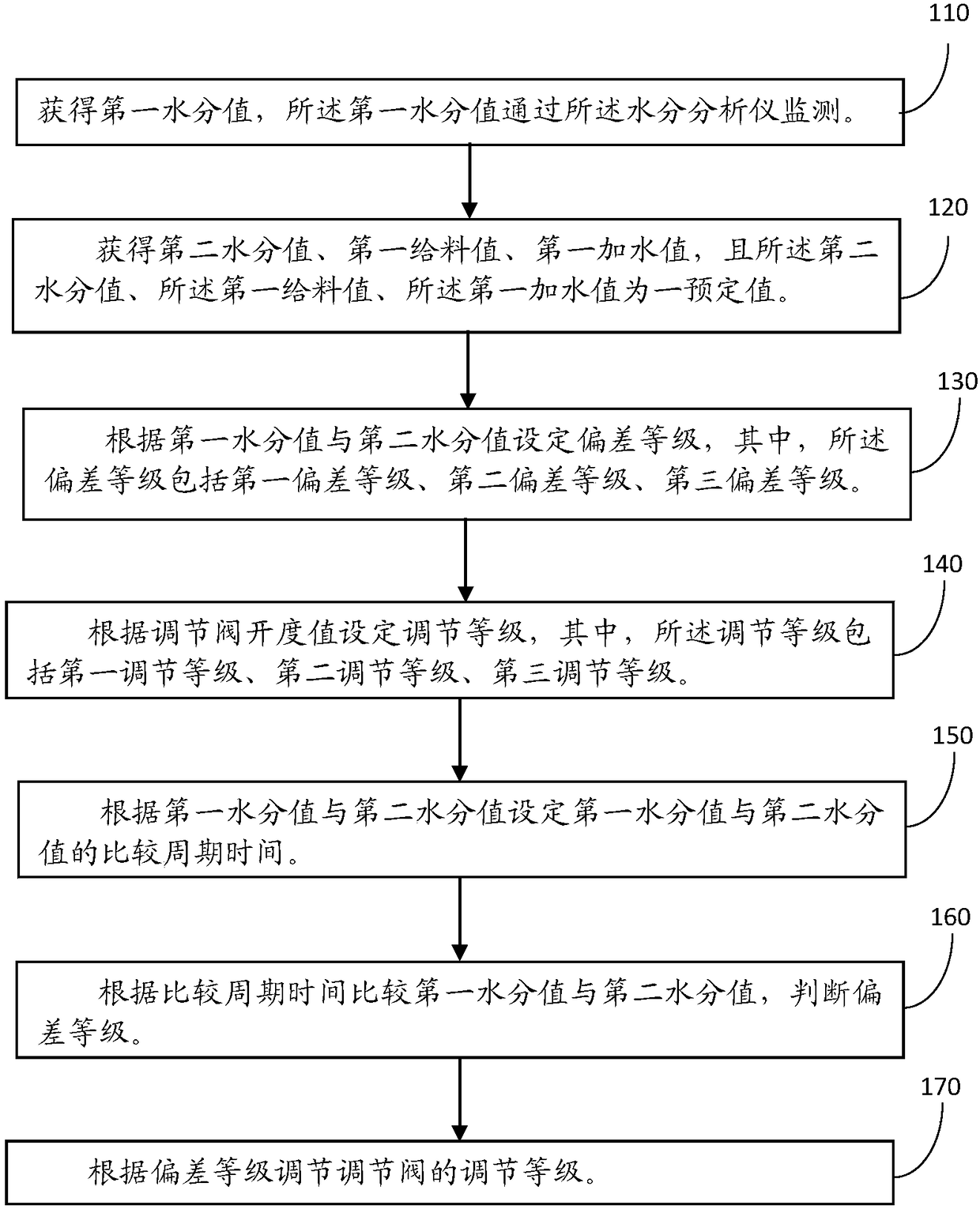

[0047] The embodiment of the present invention provides a method for controlling moisture in pellet mixture, please refer to figure 2 , the method includes:

[0048] Step 110: Obtain a first moisture value, which is monitored by the moisture analyzer 4 .

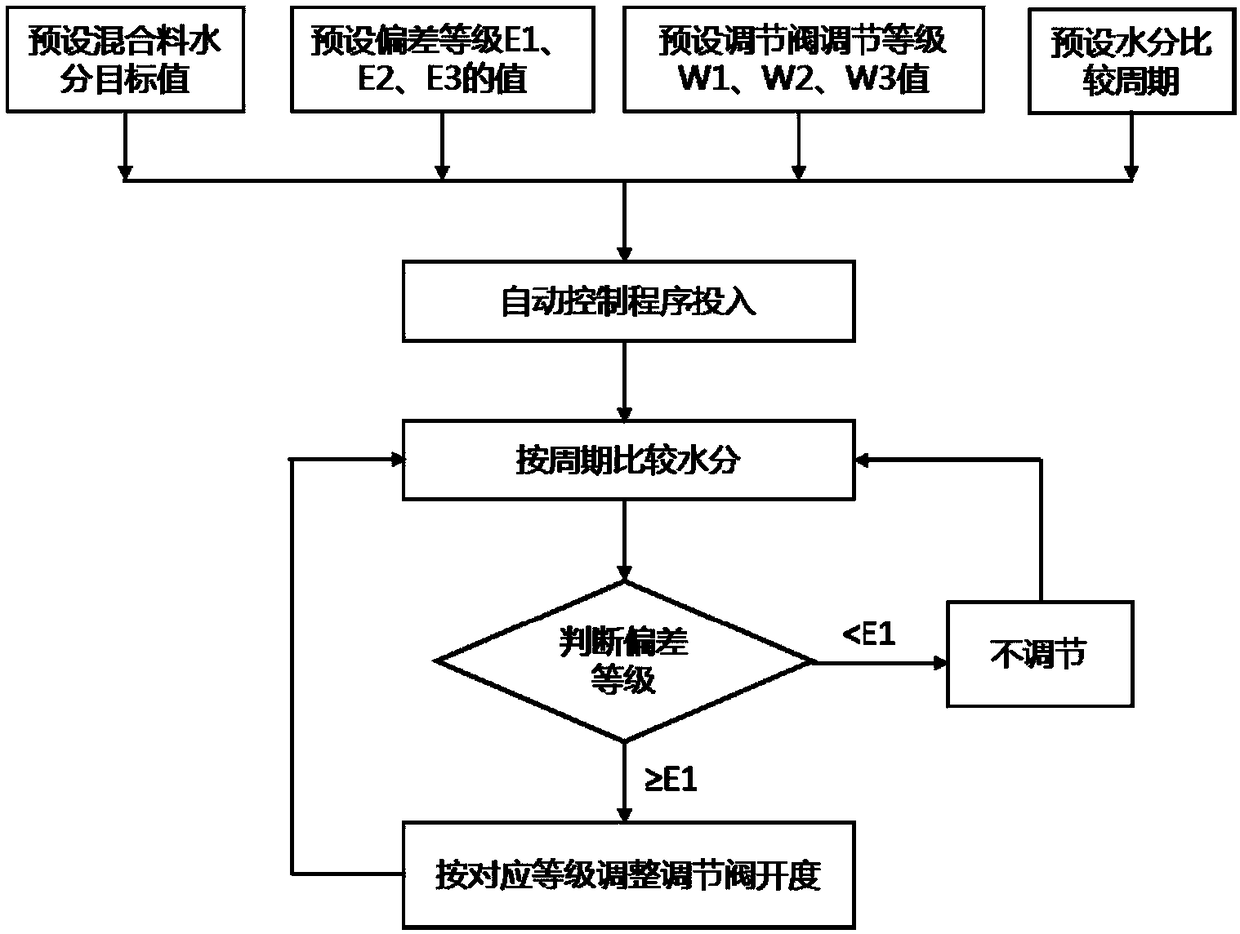

[0049] Specifically, for the pellet mixture moisture control device, a set of automatic control program can be compiled to automatically control it, and the automatic control program can read the feed amount of the mixer 2 in real time, the The detected value of the infrared moisture analyzer 4, the opening value of the electric regulating valve 6 and the flow value of the electromagnetic flowmeter 7, and the opening degree of the electric regulating valve 6 can be controlled. Therefore, firstly, the moisture of the pellet mixture is read in real time by the moisture analyzer 4, which is the first moisture value. Meanwhile, the feed amount of the mixer 2, the The opening value of the electric regulating valve 6 and the fl...

Embodiment 3

[0071] In order to illustrate the present invention more clearly, the usage method of a pellet mixture moisture control device and method of the present invention will be described in detail below. details as follows:

[0072] A said water pipe 5 is installed at the feeding end of said mixer 2 for fetching water, and a set of said regulating valve 6 and said flow meter 7 are arranged on said water pipe 5 for adjusting the amount of water fetched For monitoring, a set of moisture analyzer 4 is arranged above the second belt conveyor 3 at the discharge end of the mixer 2 for real-time monitoring of the moisture content of the mixed raw materials. Based on the above device, a set of automatic control program is used to control the addition of water during the mixing process of the pellet mixture, and the difference between the first moisture value and the second moisture value of the mixture detected by the moisture analyzer 4 in real time is compared , that is, the difference b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com