Guardrail and roadbed integrally-reinforced pile anchor structure shaped like a Chinese character 'bo' and construction method thereof

A technology of roadbed and guardrail, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve problems such as road subsidence deformation, road guardrails are not firm, reinforced roadbed deformation, etc., and achieve strong anti-collision performance and good deformation control effect , Increase the effect of anti-slip force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

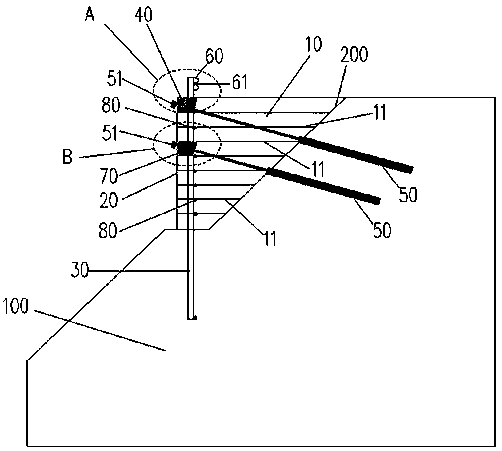

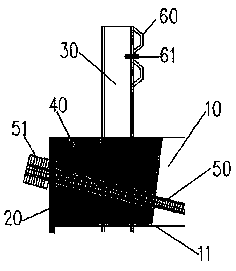

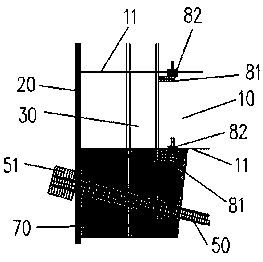

[0045] See Figure 1 to Figure 3 , A guardrail and roadbed integrated reinforcement of the Bo-shaped pile anchor structure, including a reinforced steep slope roadbed 10 provided with multiple layers of geogrids 11, panels 20 for supporting the soil, H-shaped steel piles 30, crown beams 40 and anchor 50; before the reinforced steep slope roadbed 10 is filled, the H-shaped steel pile 30 is vertically driven into the foundation to reach a stable ground 100, and the panel 20 is fixed in front of the H-shaped steel pile 30, The reinforced steep slope subgrade 10 is filled between the face plate 20 and the original slope body 200. During the filling process, each layer of geogrid 11 is connected to the face plate 20 through a first connecting member, and each layer of geotechnical The grid 11 and the H-shaped steel pile 30 are connected by a second connecting member 80 pieces or by welding; the crown beam 40 is cast along the length of the road, and the crown beam 40 is connected to...

Embodiment 2

[0053] The difference between this embodiment and the first embodiment is that this embodiment further includes a road guardrail 60 and a fixing member 61, and the road guardrail 60 is fixed on the H-shaped steel pile 30 through the fixing member 61.

[0054] The road guardrail 60 is connected to the H-shaped steel piles by the connecting fixing members 61, which is equivalent to significantly increasing the anchoring depth of the road guardrail 60 in terms of the force mechanism. When the road guardrail 60 is subjected to collision, the vertical H-shaped steel pile 30 It mainly provides bending strength, while the inclined anchor 50 mainly provides tensile strength. Through the synergistic effect of this bu-shaped pile anchor reinforcement structure, at the same time, the H-shaped steel pile 30 is connected to each layer through the iron hook 81 and the buckle 82 The geogrid 11 is connected to more effectively improve the anti-collision performance of the highway guardrail 60, th...

Embodiment 3

[0066] Please combine Figure 1 to Figure 5 The structure diagram shown is a construction method of a Bo-shaped pile-anchor structure with integrated reinforcement of guardrail and roadbed, including the following steps:

[0067] (1) Measure and loft, adopt the form of piling, and set the H-shaped steel pile 30 vertically into the stable bottom layer 100 according to the designed anchoring depth;

[0068] (2) A panel 20 is installed in front of the H-shaped steel pile 30 to support and backfill the soil;

[0069] (3) Pave backfill and geogrid 11 along the original slope 200 next to the road, connect the geogrid 11 to the panel 20 through the first connecting member, and connect the geogrid 11 through the second connecting member 80 or welding Connected with H-shaped steel pile 30, compacted and tamped the soil to fill the reinforced steep slope roadbed 10;

[0070] (4) After the reinforced steep slope subgrade 10 reaches the design elevation of the road, the crown beam 40 is poured al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com