Bridge floor anti-wave anti-collision guardrail for sea-crossing bridge

An anti-collision guardrail and anti-wave technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem of lack of anti-wave effect, etc., and achieve the effects of good durability, good fatigue resistance and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

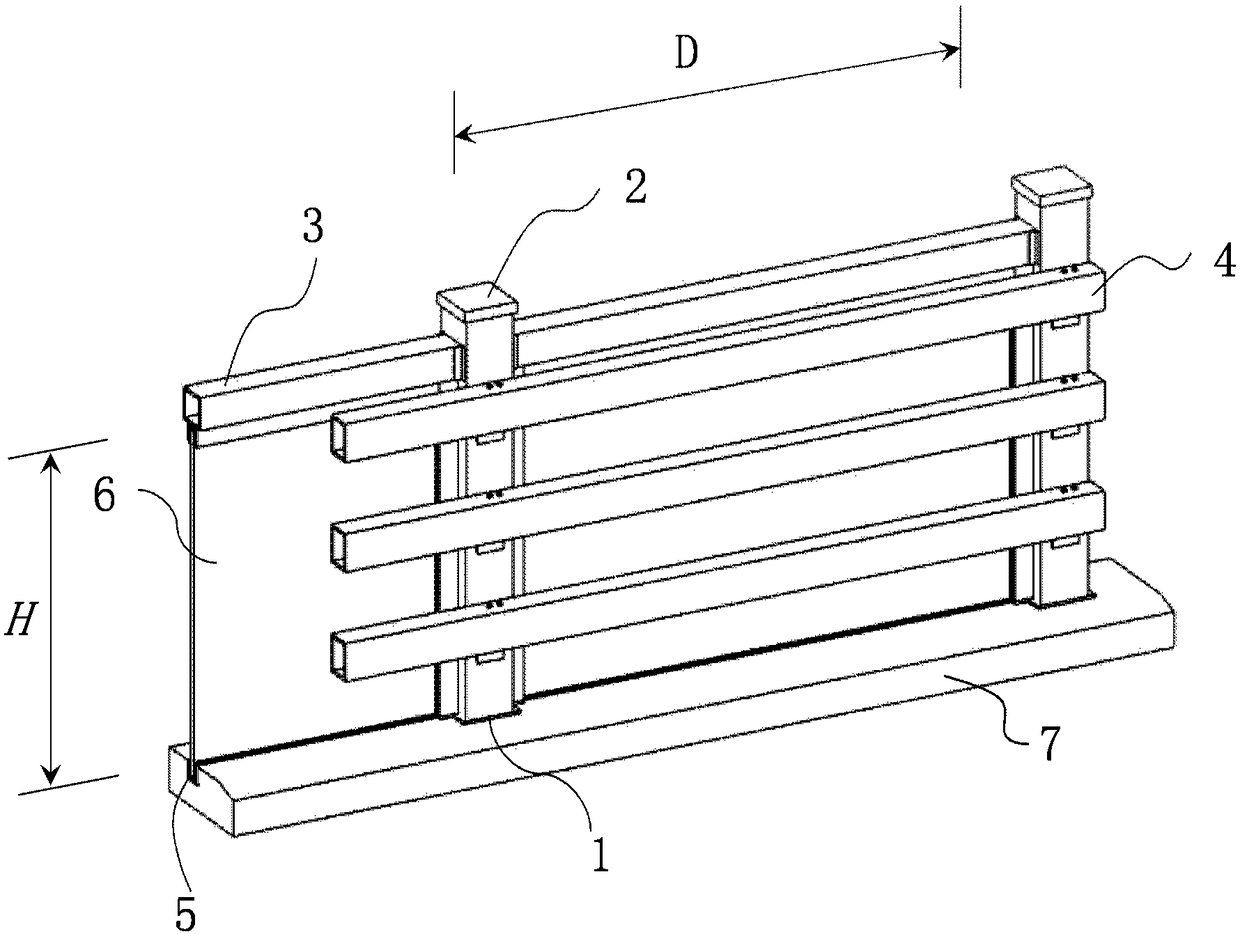

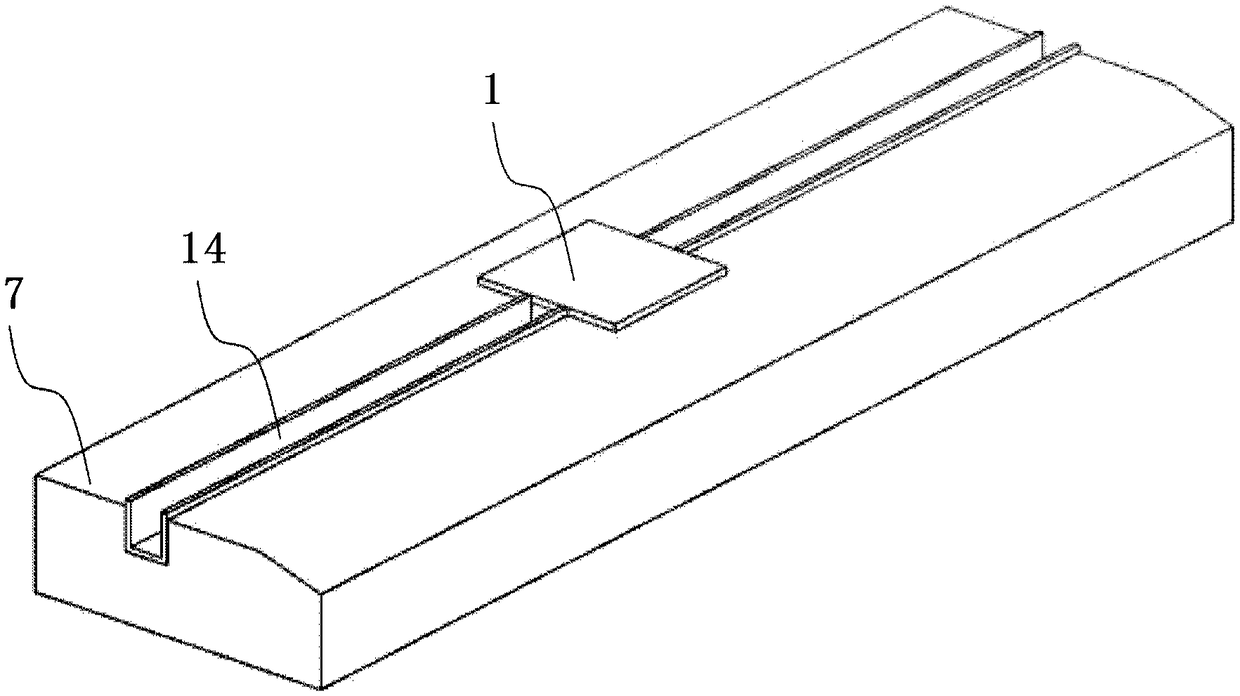

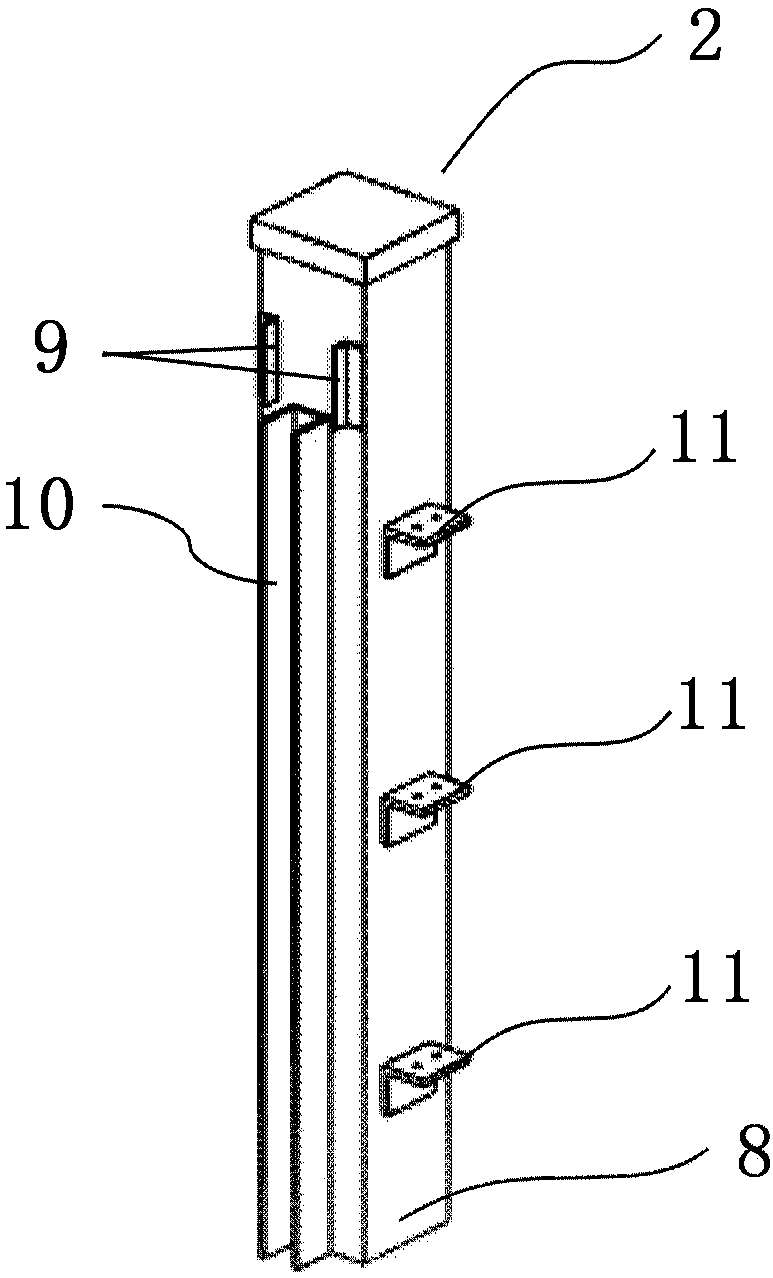

[0042] It is difficult in the existing technology to make the guardrail of the cross-sea bridge have the characteristics of blocking repeated waves, measuring the wave force of overcoming waves, fatigue resistance, durability, easy maintenance and good landscape effect. In view of this, the present invention provides a Anti-wave and anti-collision barriers for bridge decks across the sea. The anti-wave baffle 6 of the guardrail and the column 2, the upper beam 3 and the bridge curb 7 constitute a light-transmitting and impermeable anti-wave barrier to the outside, while the upper beam 3, the anti-collision beam 4 and the column 2 constitute The anti-collision barrier on the inner side has good landscape effect, can prevent waves, wind and collision, and significantly improve the driving environment. In addition, the "Z" shaped distributed optical fiber sensor 17 of the anti-wave baffle 6 can accurately measure the wave force and its distribution over the waves.

[0043] In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com