Inclined pile construction equipment, inclined pile construction method and inclined pile deep foundation pit support structure

A technology of construction equipment and construction methods, which is applied in basic structure engineering, excavation, sheet pile wall and other directions, can solve the problems of slow pile formation, slow construction, difficult recycling and reuse, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

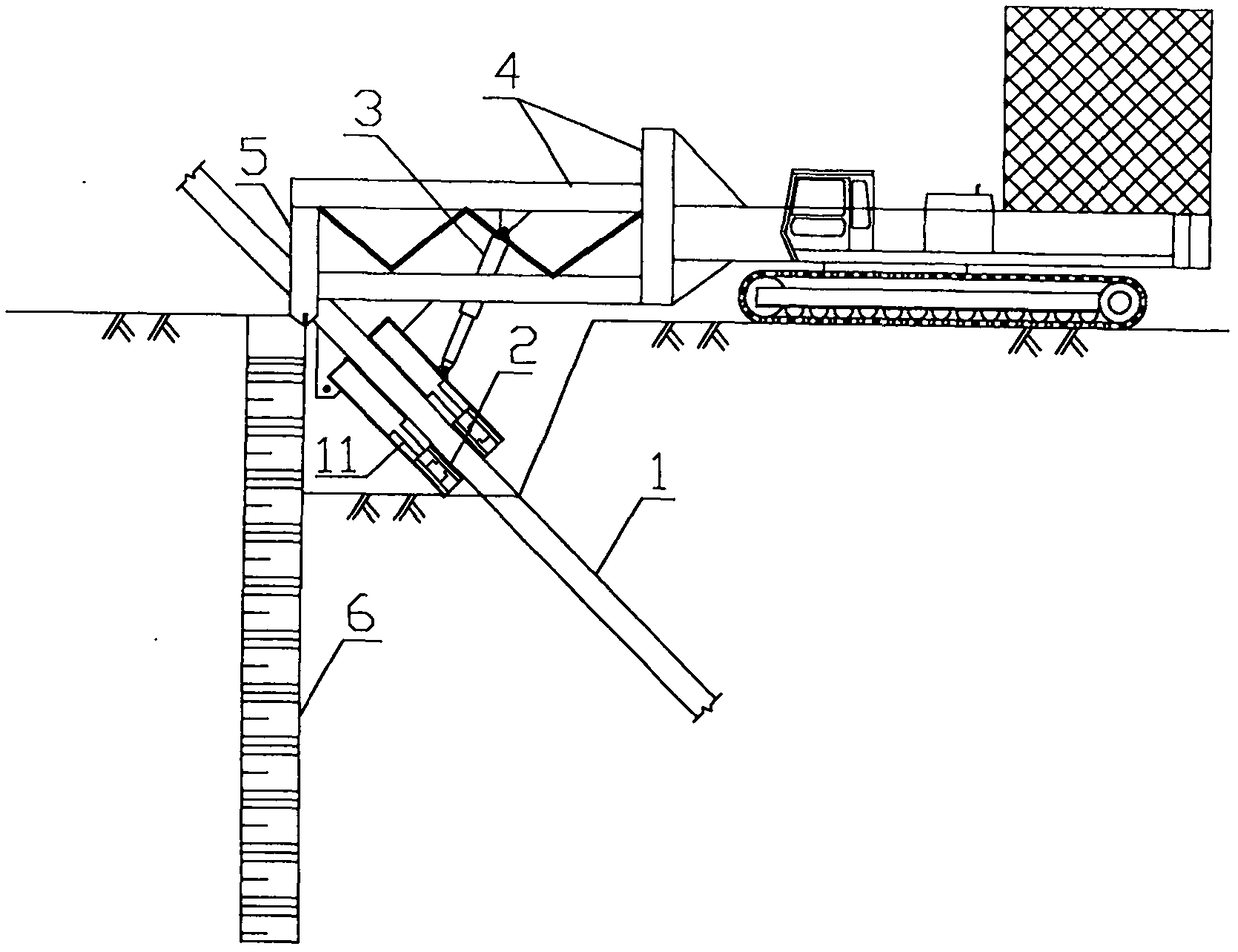

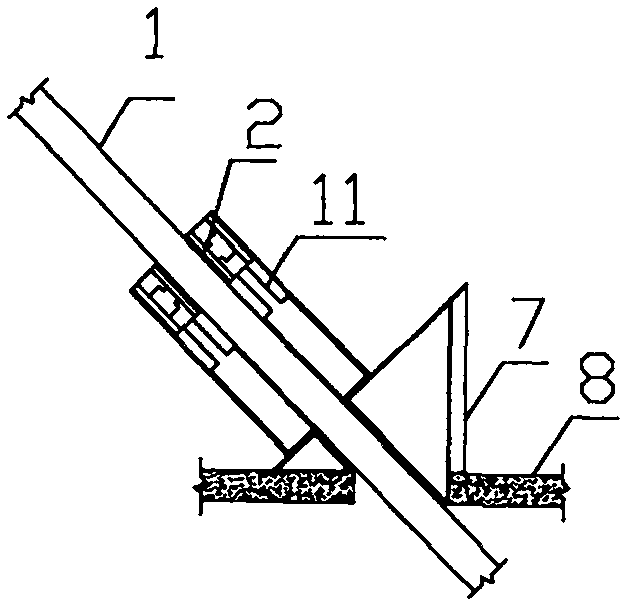

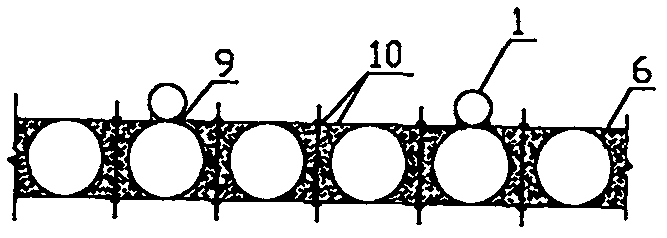

[0078] as such figure 1 and image 3 , Figure 4 The shown first embodiment of the present invention mainly introduces the structure, working principle and usage method of the first inclined pile construction equipment of the present invention. The schematic diagram of the structure structure of the first inclined pile construction equipment of the present invention is as follows: figure 1 Shown, comprise enclosure pile connector 5, mechanical base 4, inclined pile connector 2, power unit 11, inclined pile angle control device 3 five parts, wherein mechanical base 4 is crawler type or walking type device that can walk or In other structural forms, the main function of the mechanical base 4 is to connect with other components, and it is best to have a self-propelled function; the inclined pile connector 2 is a hollow device that can be connected to the mechanical base 4 and can be firmly connected to the inclined pile 1, and the inclined pile is connected. The main function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com