Air intake mixing device for gas engine

A technology for gas engines and mixing devices, applied in combustion engines, engine components, machines/engines, etc., to solve problems such as fluctuation differences, affecting the normal operation and reliability of the engine, and knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

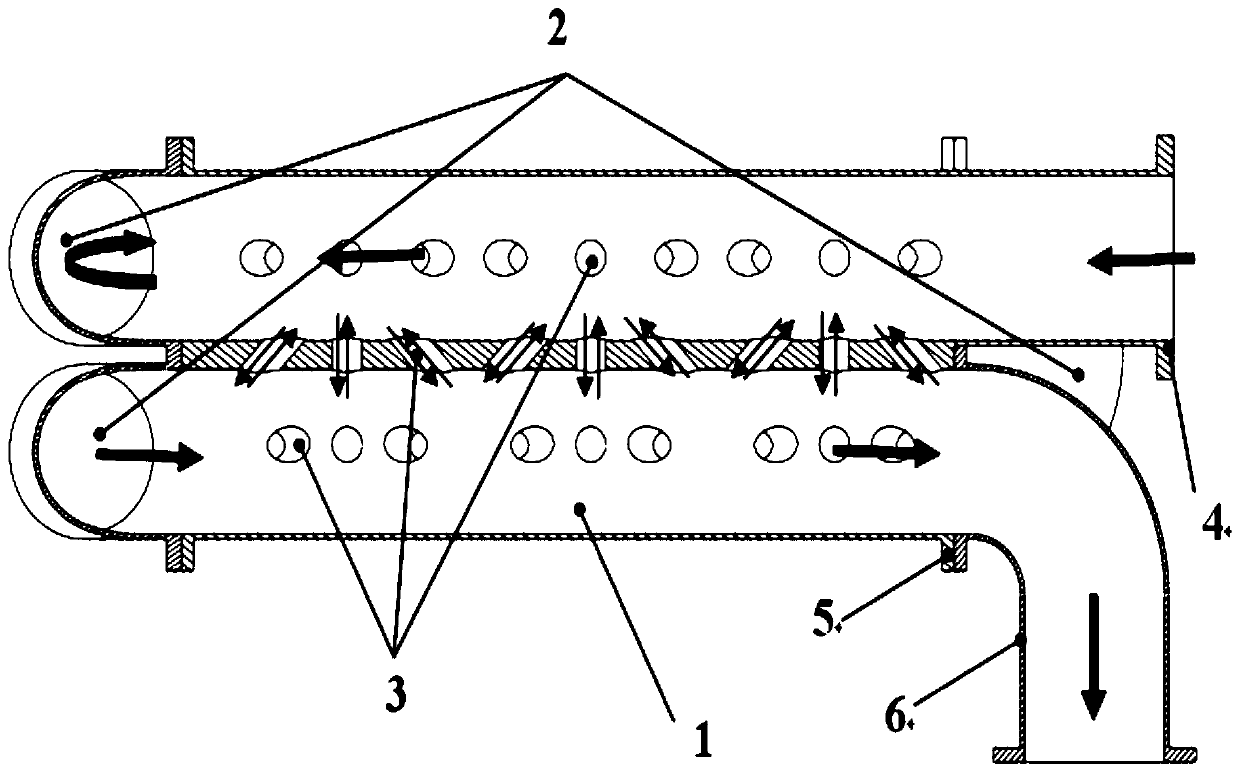

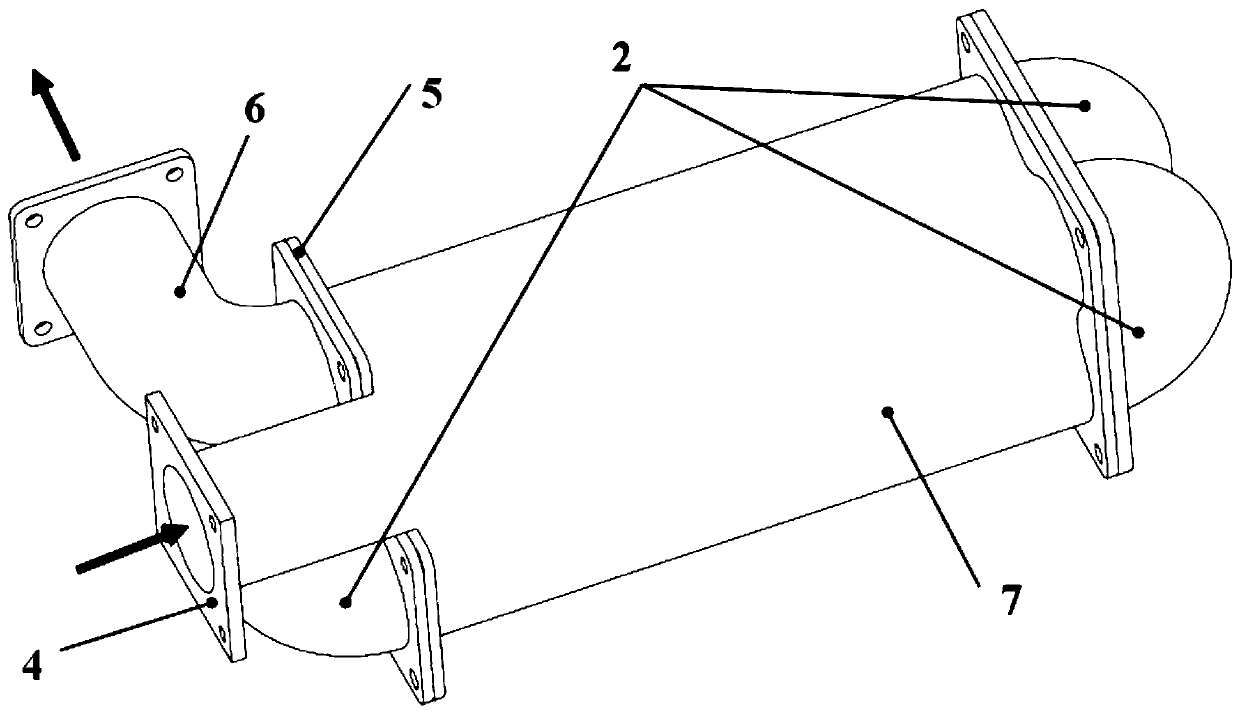

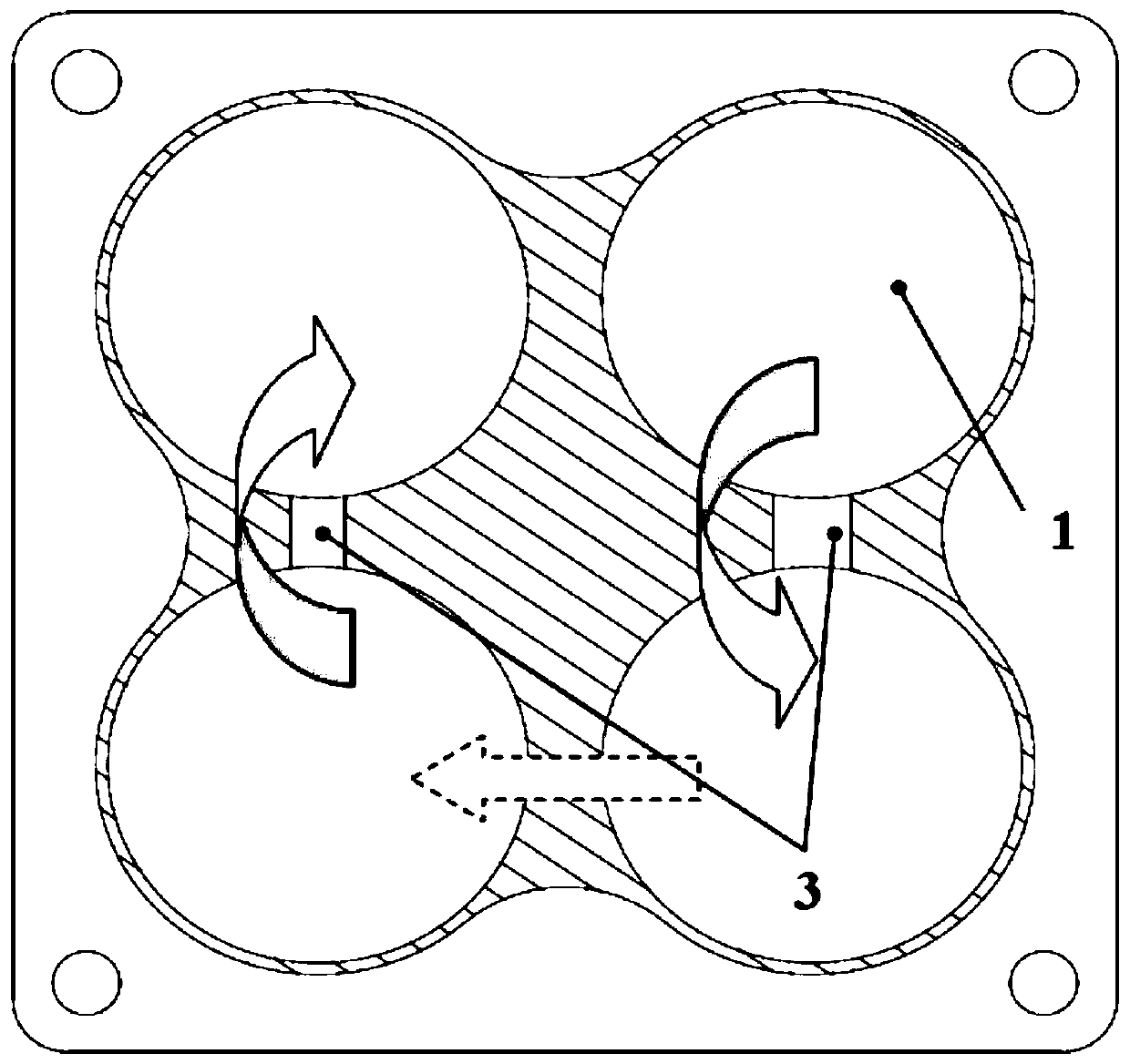

[0024] A gas engine intake mixing device of the present invention can refer to the appendix Figures 1~6 description, the arrow is the direction of gas movement,

[0025] A gas engine intake air mixing device, the intake air mixing device is located between a gas fuel and EGR mixer and an engine intake manifold, including several mixing pipelines 1 arranged in the same direction and connections on both sides of the mixing pipeline In pipeline 2, several mixing pipelines 1 with the same arrangement direction form a mixed pipeline group 7; and the connecting pipeline to form a series flow channel of the intake mixture;

[0026] The flange includes an inlet connection flange 4 and an outlet connection flange 5, the inlet connection flange connects the gas fuel and the outlet pipeline behind the EGR mixer 10, and the outlet connection flange 5 passes through the intake pipe elbow 6 and the outlet pipe. The engine intake manifold is connected;

[0027] One side of the gas fuel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com