Tilting-pad sliding bearing

A sliding bearing and bearing housing technology, applied in the directions of bearings, bearing components, shafts and bearings, can solve the problems of increasing the bearing cross stiffness damping coefficient, complicated installation of tilting pad bearings, high fulcrum contact stress and fatigue, etc. Eliminate wear, increase stiffness and damping, and improve vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

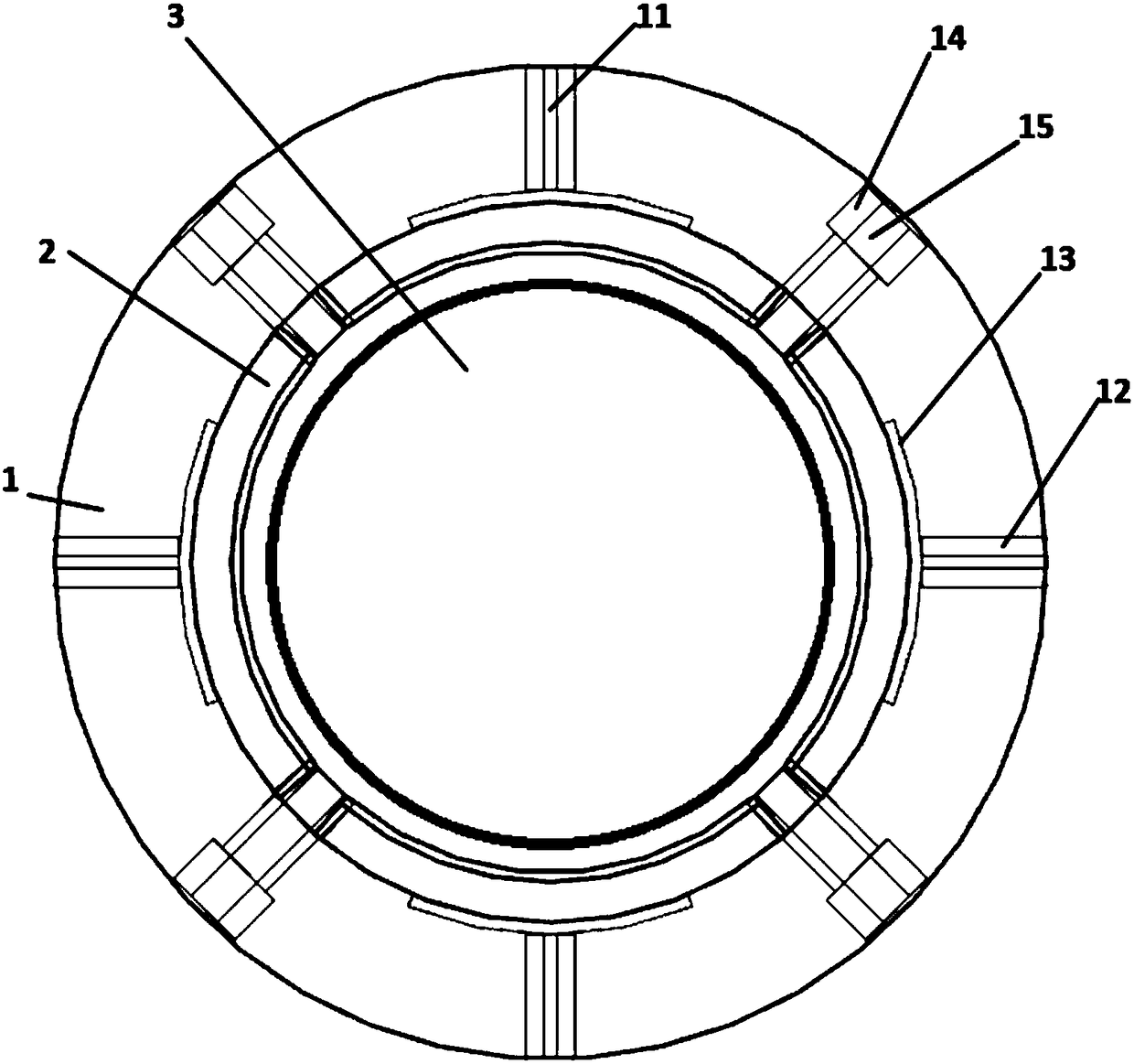

[0026] Such as figure 1 as shown, figure 1 It is a three-dimensional structure view of the tilting pad sliding bearing; the tilting pad sliding bearing includes a bearing housing 1, and the bearing housing 1 is arranged as a hollow cylindrical structure, and on the inner surface of the bearing housing 1 A number of pads 2 are arranged, and the pads 2 are evenly distributed in a ring shape around the central axis of the bearing housing 1 ; the rotor 3 is arranged in the ring structure formed by the pads 2 . Both sides of the bearing housing 1 are connected to the bearing end cover by bolts.

[0027] The bearing housing 1 can be configured as an integral structure or a split structure. The tilting pad sliding bearings can be divided into three-watt, four-watt, five-watt and other multi-watt tilting pad bearings according to the number of the pads 2

[0028] The bearing housing 1 is provided with several throttle holes 11 in the radial direction. Preferably, the throttle holes...

Embodiment 2

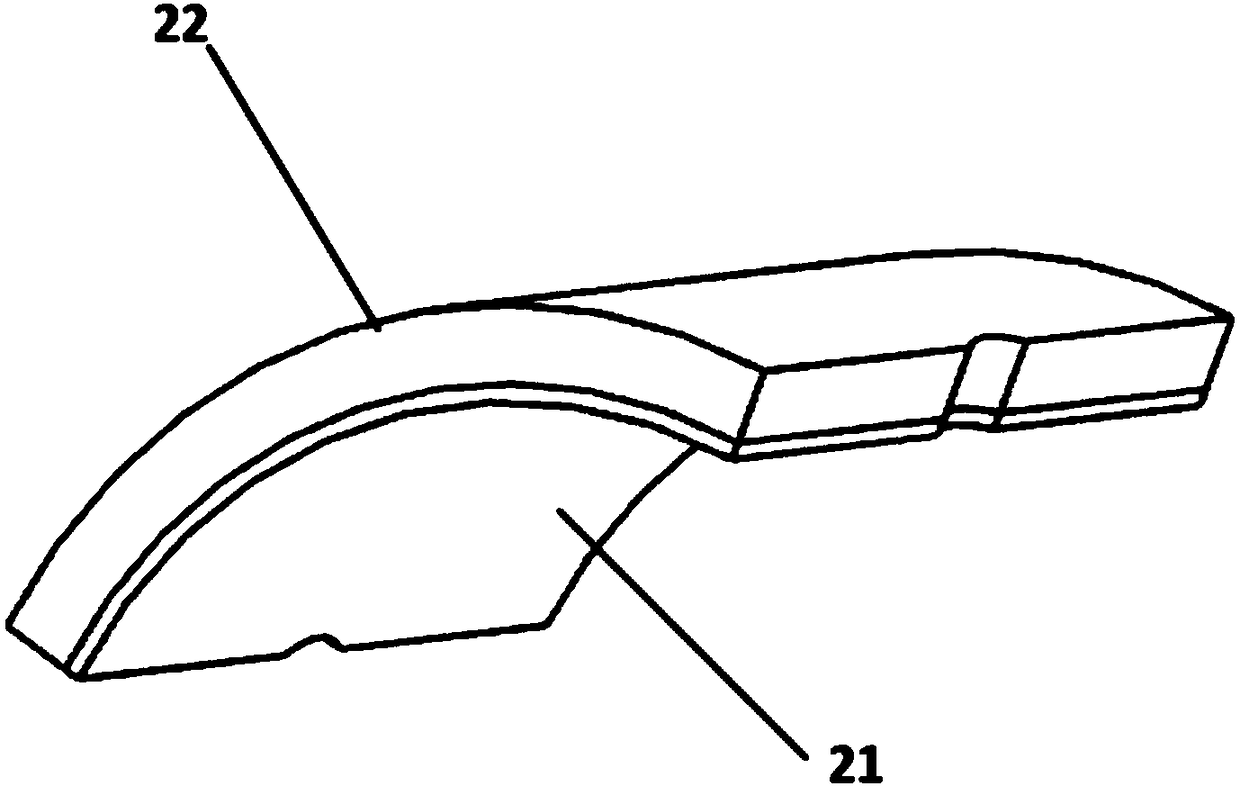

[0032] In this embodiment, the tilting pad sliding bearing includes four pads 2; the pads 2 are arc-shaped, such as image 3 as shown, image 3 It is a structural view of the tile; the tile 2 includes a friction-reducing layer 21 and a tile back base 22, and the friction-reducing layer 21 is fixedly arranged on the end surface of the tile back base 22 opposite to the rotor 3; And in order to better form an inner hydrodynamic lubricating film and an outer hydrostatic film on the two arc-shaped end surfaces of the tile 2, the tile 2 has a certain preload coefficient.

[0033] The preload coefficient m reflects the degree of convergence of the oil wedge on the inner surface of each of the pads 2; specifically, the greater the preload coefficient m, the greater the degree of convergence of the oil wedge on the inner surface of the tile 2, which can force The lubricating medium enters the convergent gap to increase the oil wedge force acting on the rotor journal, thereby tightly c...

Embodiment 3

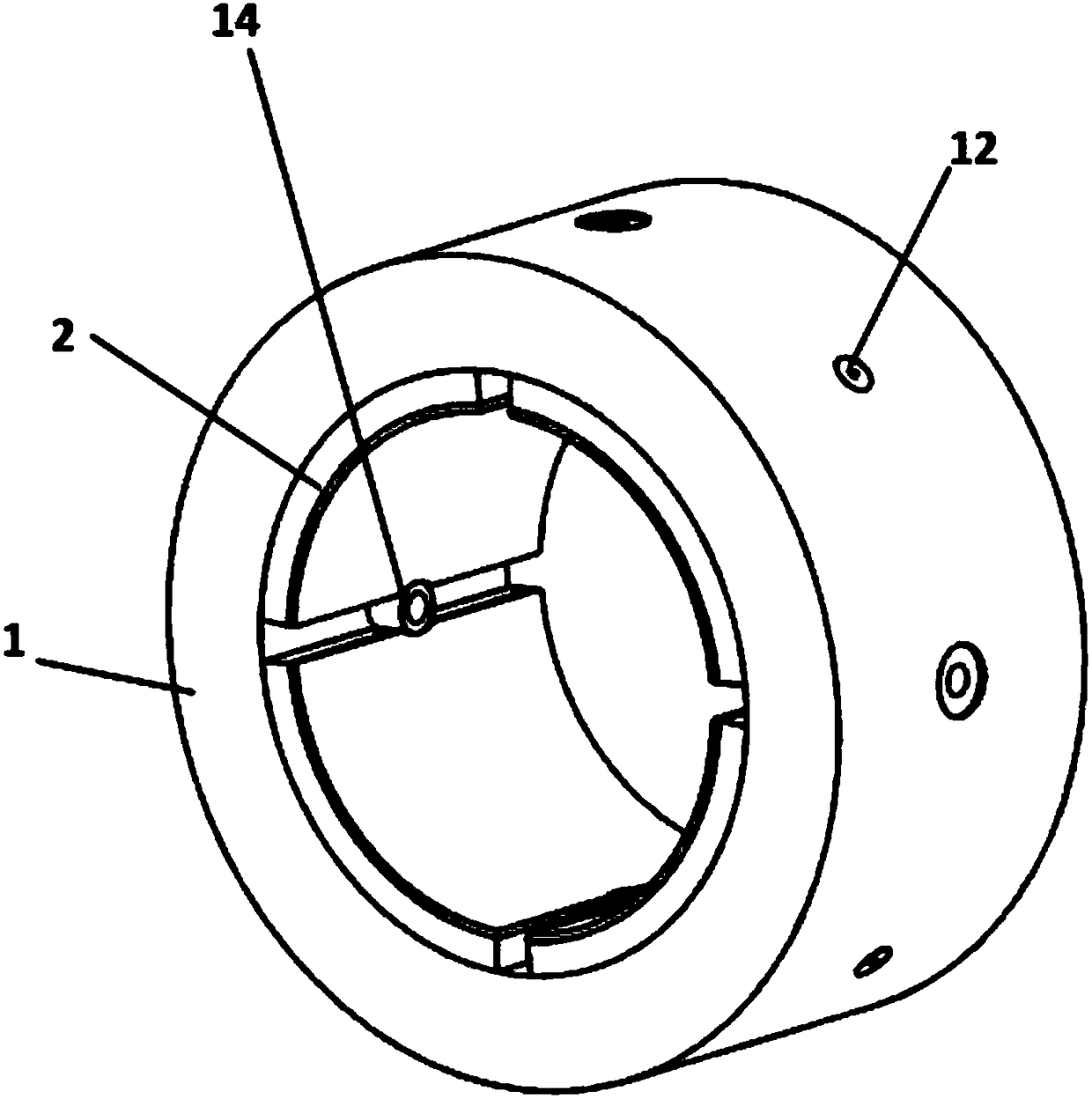

[0040] Embodiment 3 is further improved on the basis of Embodiment 1. In this embodiment, the bearing housing 1 is provided with a throttle 12 radially, and the throttle 12 is detachably fixed on the bearing housing 1; the throttle hole 11 is arranged on the throttle 12 Above; the cross-sectional size of the orifice 11 can be freely set by replacing the restrictor 12, so as to adjust the flow rate of the lubricating medium through the orifice 11 and other parameters. Such as Figure 4 as shown, Figure 4 It is a structural view of the bearing housing; the tilting pad sliding bearing also includes a static pressure shallow chamber 13, and the static pressure shallow chamber 13 is arranged on the bearing housing 1 or / and the pad 2, The static pressure shallow chamber 13 is set at the inner end of the bearing housing 1 corresponding to the throttle hole 11, that is, enters the gap between the bearing housing 1 and the pad 2 through the throttle hole 11 The internal lubricating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com