Bottom shell structure and air conditioner with same

A shell structure and air conditioner technology, applied in the field of air conditioners, can solve the problems of wind resistance, large bending angle, surge noise, and condensation water generation, and achieve the effects of avoiding structural instability, preventing bending deformation, and preventing breakage and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

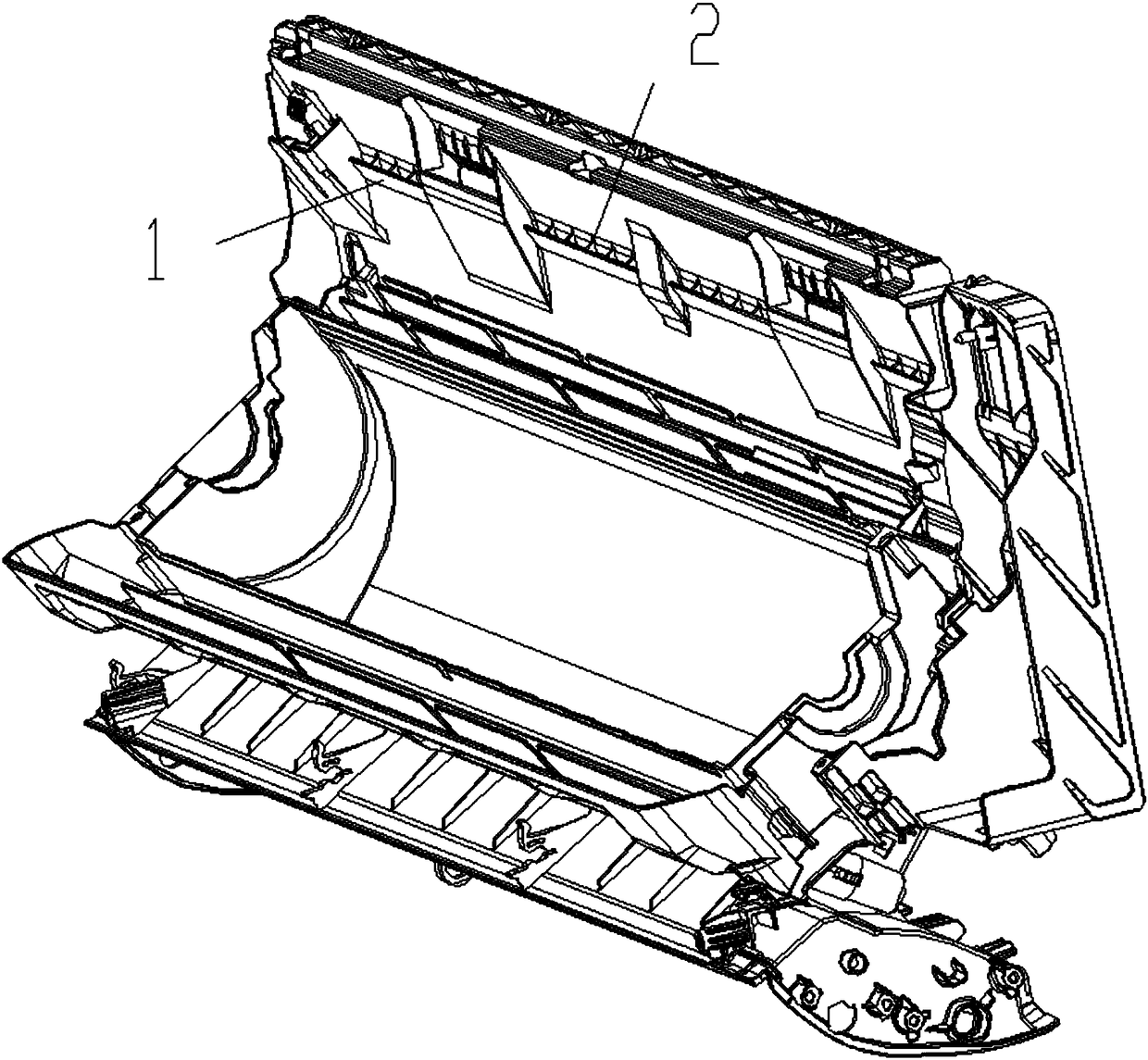

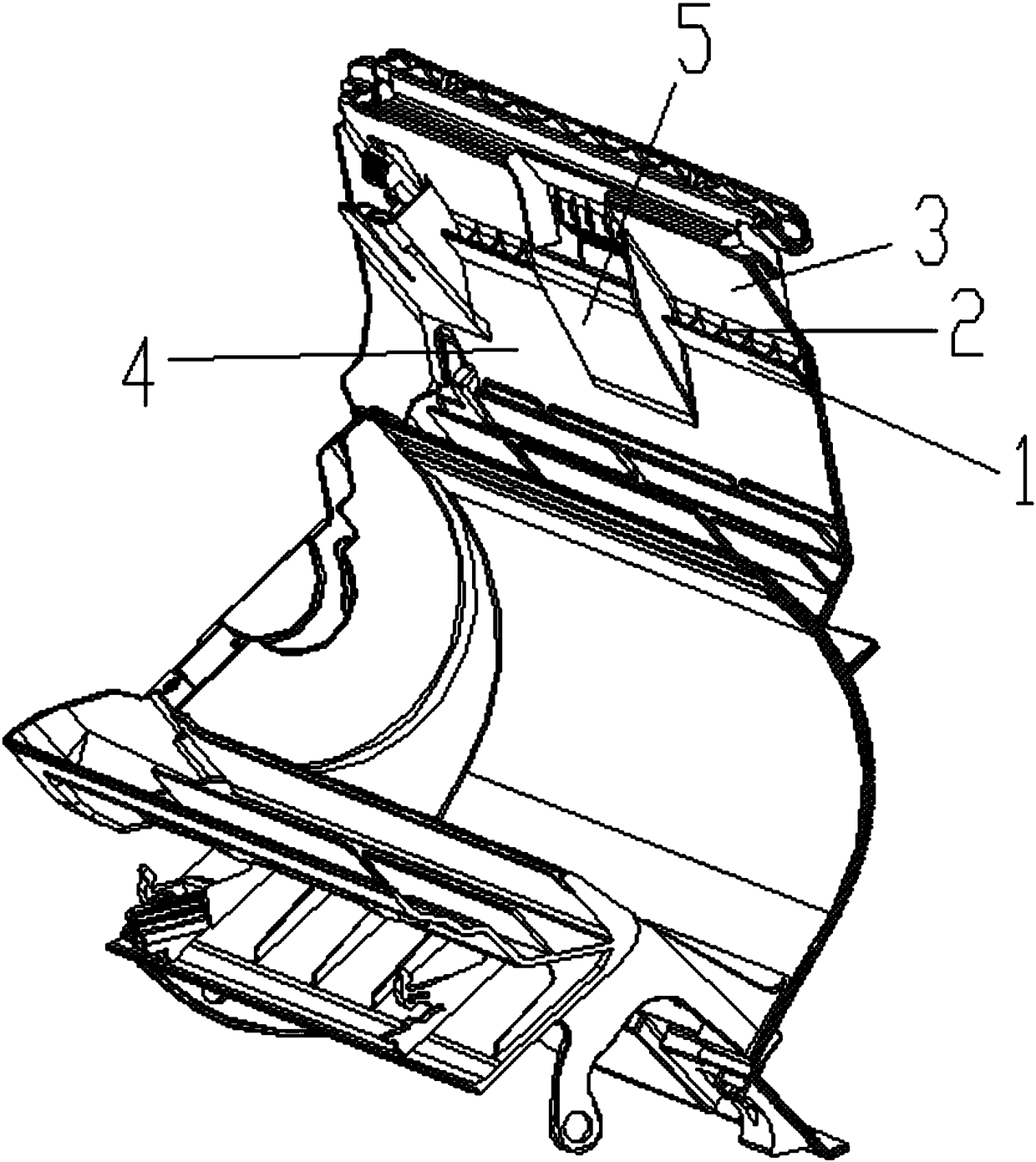

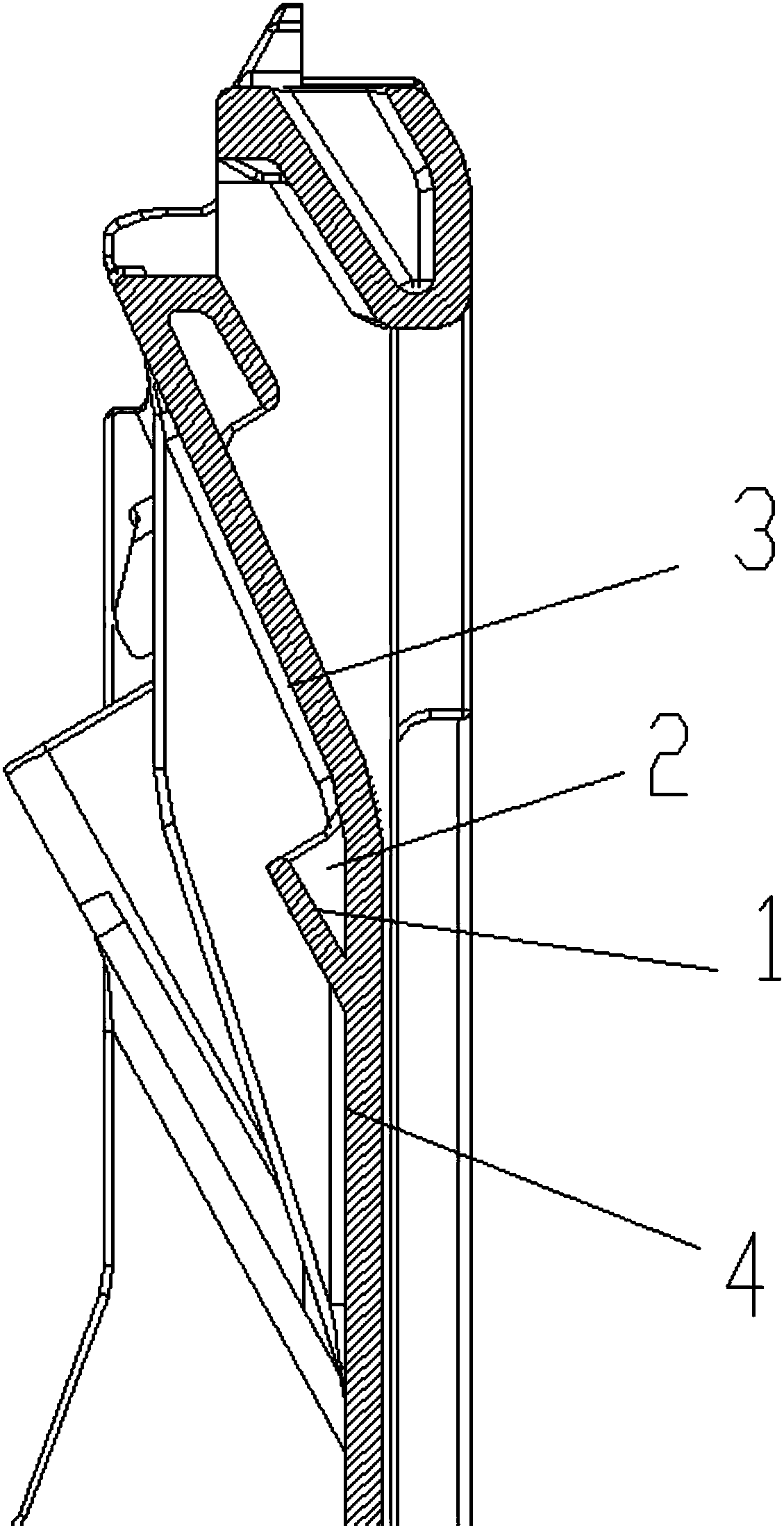

[0037] Such as Figure 1-2 As shown, the present invention provides a bottom shell structure, which is used to realize the assembly with the air conditioner heat exchanger assembly, including:

[0038] The first windward surface 3 is used to gather or block the wind;

[0039] The second windward surface 4 intersects with the first windward surface 3 to make wind flow along the first windward surface 3 to the second windward surface 4, thereby changing the wind direction;

[0040] Several second reinforcing ribs 2, which are configured as short rib-like structures, are arranged at the bend where the first windward surface 3 and the second windward surface 4 intersect, and are perpendicular to the first windward surface 3 and the second windward surface at the same time. The second windward side 4;

[0041] A plurality of first reinforcing ribs 1, the roots of which are connected to the second windward surface 4, are arranged obliquely on the second windward surface 4 as a who...

Embodiment 2

[0048] As the above-mentioned bottom shell structure, the difference of this embodiment is that, in combination with figure 1 with figure 2 As shown, the first reinforcing rib 1 is arranged intermittently, and several protrusions 5 are arranged at the discontinuity, and the protrusions 5 are distributed on the folds of the first windward surface 3 and the second windward surface 4 The corner is connected to both the first windward surface 3 and the second windward surface 4 , and both sides of the protruding portion 5 are in contact with the first reinforcing rib 1 . The cooperative design of the protruding portion 5 and the first rib 1 effectively further strengthens the strength of the bend, and at the same time, the contact connection with the first rib 1 can prevent the first rib from 1 The occurrence of the problem of reduced stability caused by too long.

Embodiment 3

[0050]As the above-mentioned bottom shell structure, the difference of this embodiment is that, in combination with figure 1 with figure 2 As shown, the second reinforcing ribs 2 are distributed in a longitudinal array at the bend between the first windward surface 3 and the second windward surface 4, a plurality of the second reinforcing ribs 2 are arranged at intervals, and the first The quantity of the second reinforcing rib 2 increases with the increase of the length of the first reinforcing rib 1, the longer the length of the first reinforcing rib 1, the more the number of the second reinforcing rib 2, so that the bending strength is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com