Efficient and fully-automatic cut tobacco separation system

A separation system, fully automatic technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of low recovery efficiency and low recovery rate of shredded tobacco, which is unfavorable to the health of operators, so as to improve the speed, ensure the recovery rate, and improve the recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

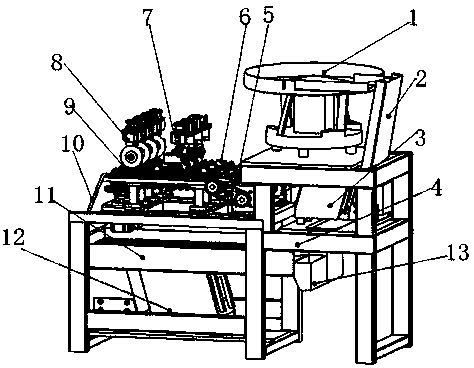

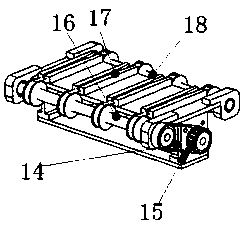

[0022] As shown in the figure, a high-efficiency automatic shredded tobacco separation system includes a frame 4, which is characterized in that the frame 4 is provided with a vibrating plate 1, a linear vibrating feeder 3, a belt clamping feeder 5, a color Sensor 6, cutter module 7, knife sharpening mechanism 8, roller conveyor 9, discharge guide trough 10 and linear vibration screening module 12;

[0023] The vibrating plate 1 is installed on the frame 4, and the discharge port of the vibrating plate 1 is connected to the channel entrance of the channel dividing device. The channel dividing device is provided with three branches, and the channel dividing device The lane-dividing outlet of the channel is connected with the material guide groove 2 installed on the frame 4, and the lower end of the material guide groove 2 is also connected with the linear vibrating feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com