Iso-octyl palmitate cycle production processing system

A technology of isooctyl palmitate and processing system, which is applied in the field of isooctyl palmitate cycle production and processing system, can solve the problems of physical injury of workshop staff, inaccurate control of addition amount, impact on product quality, etc., and improve utilization rate , good separation and recovery, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

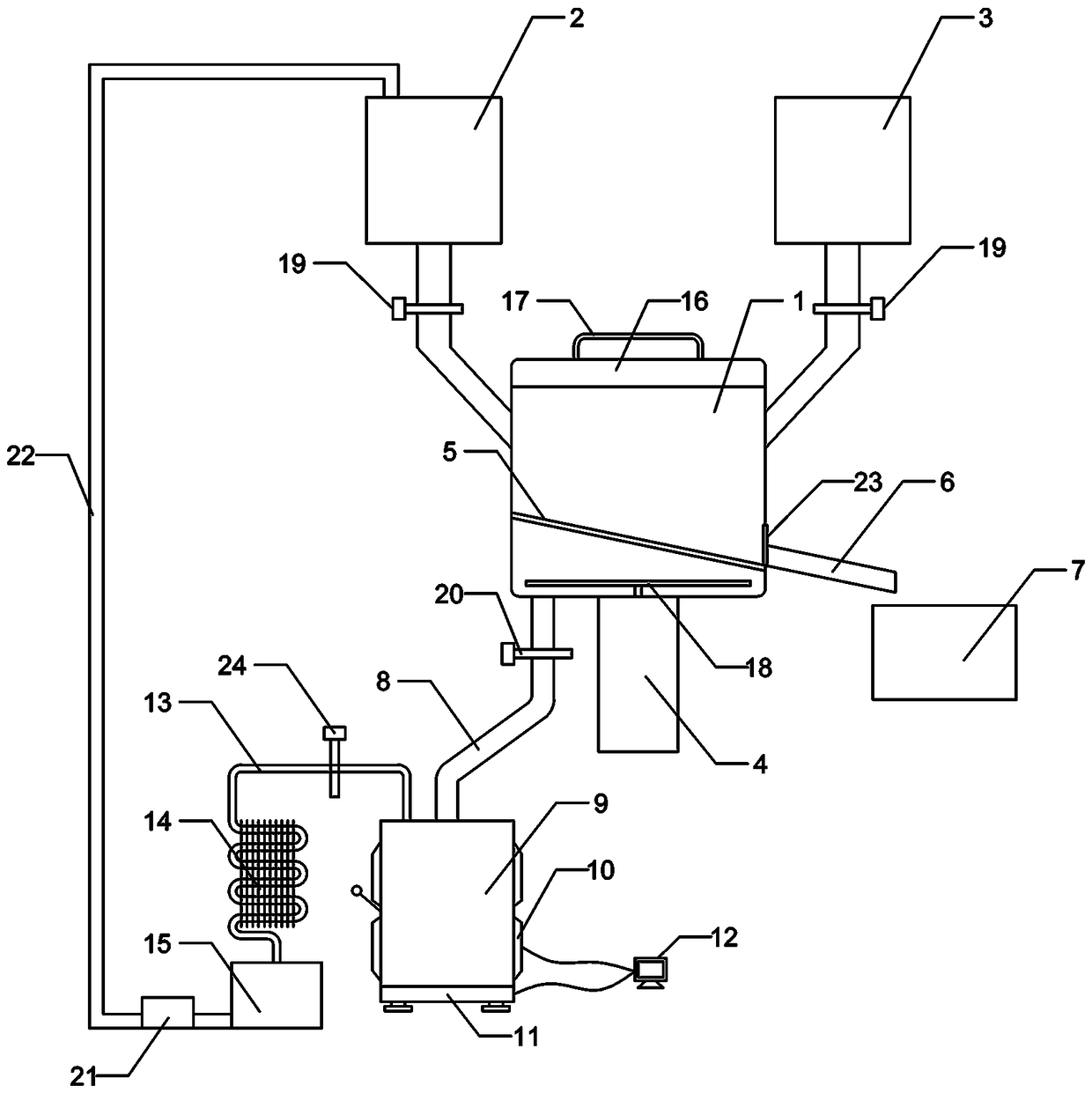

[0020] As shown in the figure, a circulation production and processing system of isooctyl palmitate includes a reaction tank 1, an isooctyl alcohol storage tank 2 and a palmitic acid storage tank 3, and the two sides above the reaction tank 1 are respectively provided with an isooctyl alcohol storage tank 2 and a The palmitic acid storage tank 3, the isooctyl alcohol storage tank 2, the palmitic acid storage tank 3 and the reaction tank 1 are all connected by connecting pipelines;

[0021] A liquid output pipe 8 is provided below the reaction tank 1, and the liquid output pipe 8 is connected to the reaction tank 1 and the distillation tank 9. The outer wall of the distillation tank 9 is wrapped with a heating jacket 10, and the distillation tank 9 is also provided with a steam output pipe 13, and the steam output The pipe 13 is connected with the isooctyl alcohol recovery tank 15, and the steam output pipe 13 is provided with a condensation section 14. A delivery pump 21 is al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com