3D (Three Dimensional) molding device and method of DMD (Digital Mirror Device) scanning imaging

A scanning imaging and molding device technology, applied in the field of 3D printing, can solve the problems of molding precision impact, molding size limitation, etc., and achieve the best technical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

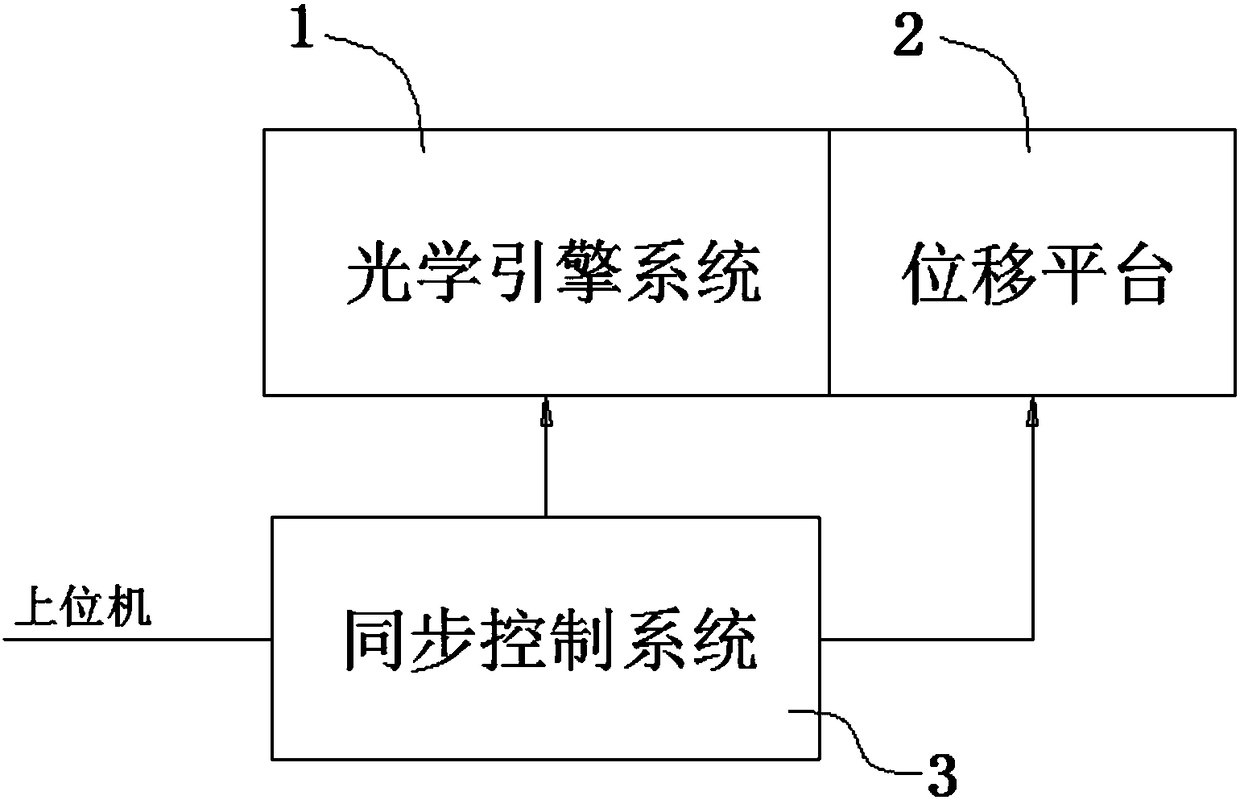

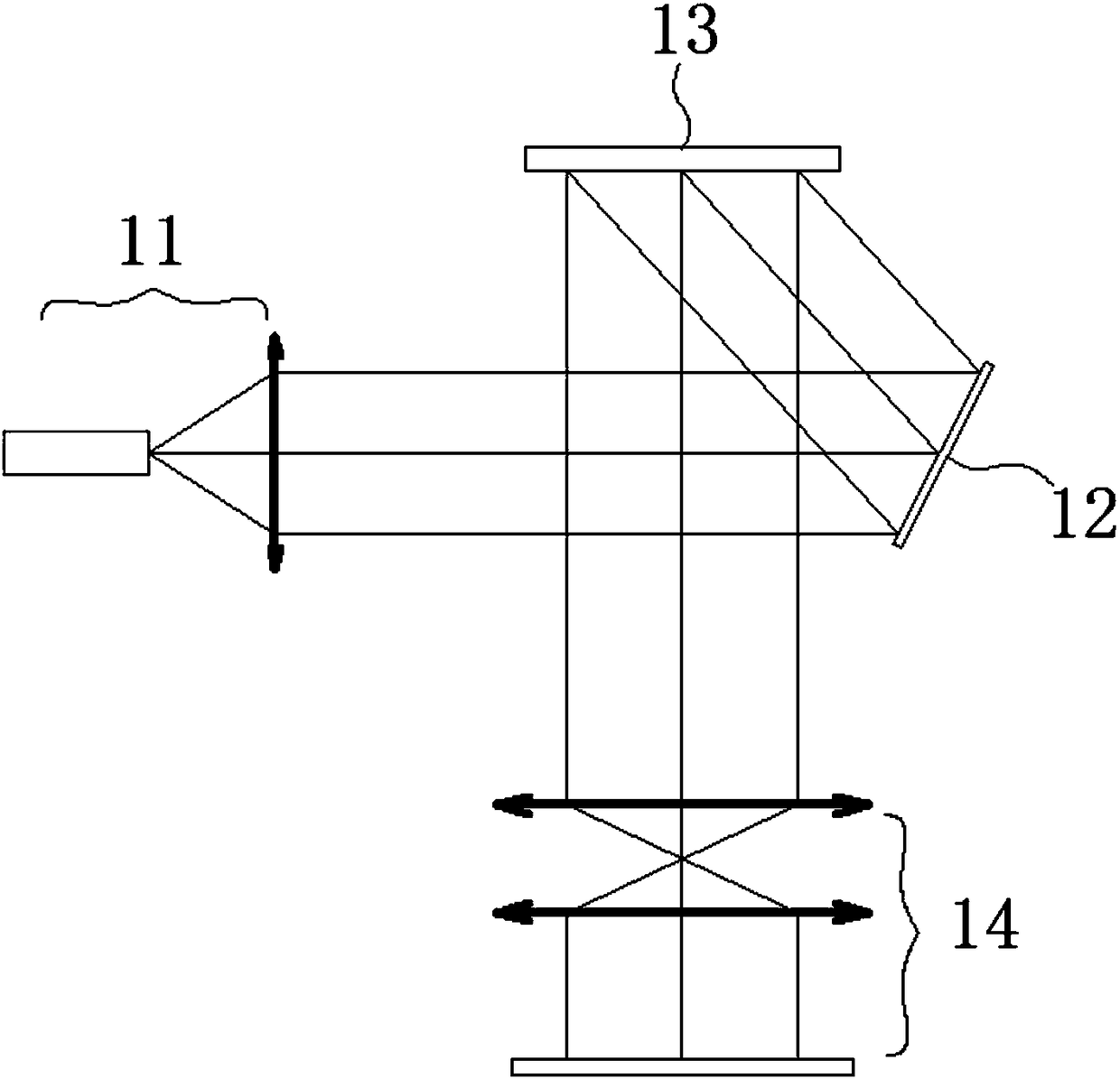

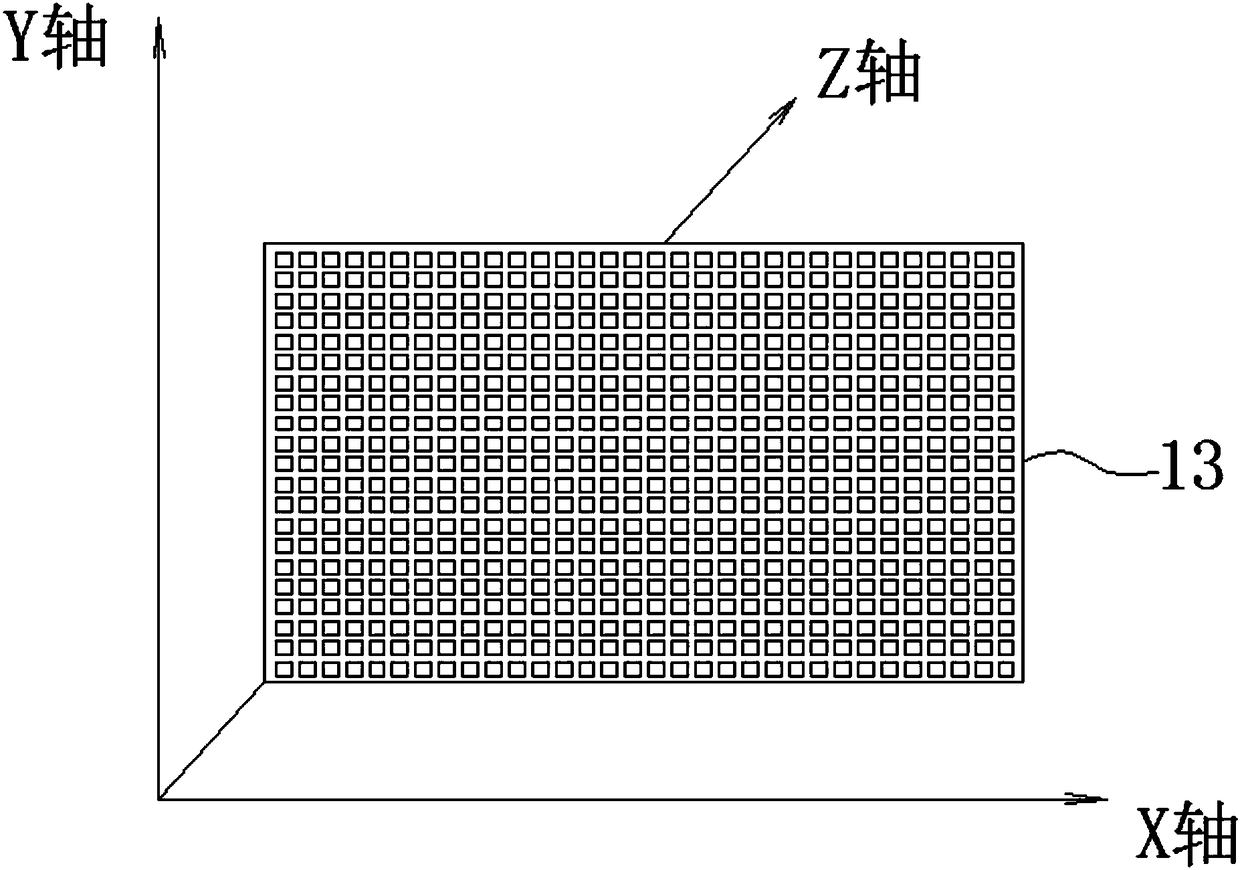

[0020] See attached Figures 1 to 4 , a 3D molding device for DMD scanning imaging, which includes an optical engine system 1, a displacement platform 2 and a synchronous control system 3, the displacement platform 2 has three-axis motion directions of X, Y and Z, and the optical engine system 1 is fixed The displacement on the XY plane is realized on the displacement platform 2, which includes a light source 11, a reflector 12, a DMD array 13 and a scanning lens 14; the displacement platform 2 and the optical engine system 1 are controlled in linkage by the synchronous control system 3, The synchronous control system 3 is connected to a host computer to acquire action instructions and execute them. The DMD array 13 is facing the scanning lens 14, and the light source 11 establishes an optical path to the DMD array 13 through the reflector 12. The light sourc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap