Automatic winding and bagging mechanism for medical catheter and winding and bagging method of automatic winding and bagging mechanism

A medical catheter and wrapping bag technology is applied to the field of automatic wrapping and bagging mechanisms for medical catheters, which can solve the problems of hidden secondary pollution, low efficiency and unsightly appearance of manual coiling, and achieves the solution of manual coiling and packaging efficiency and packaging. Convenient bag, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

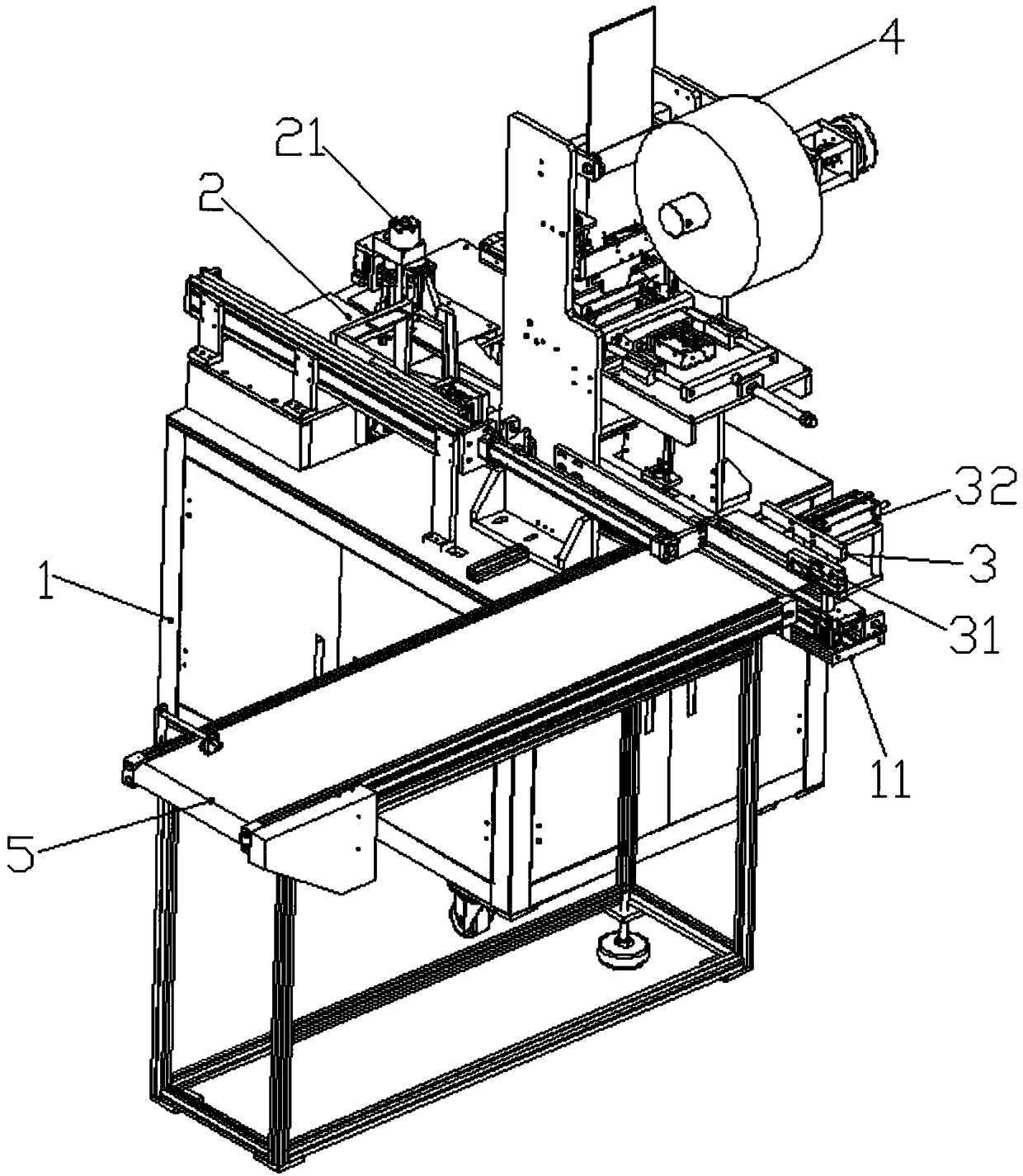

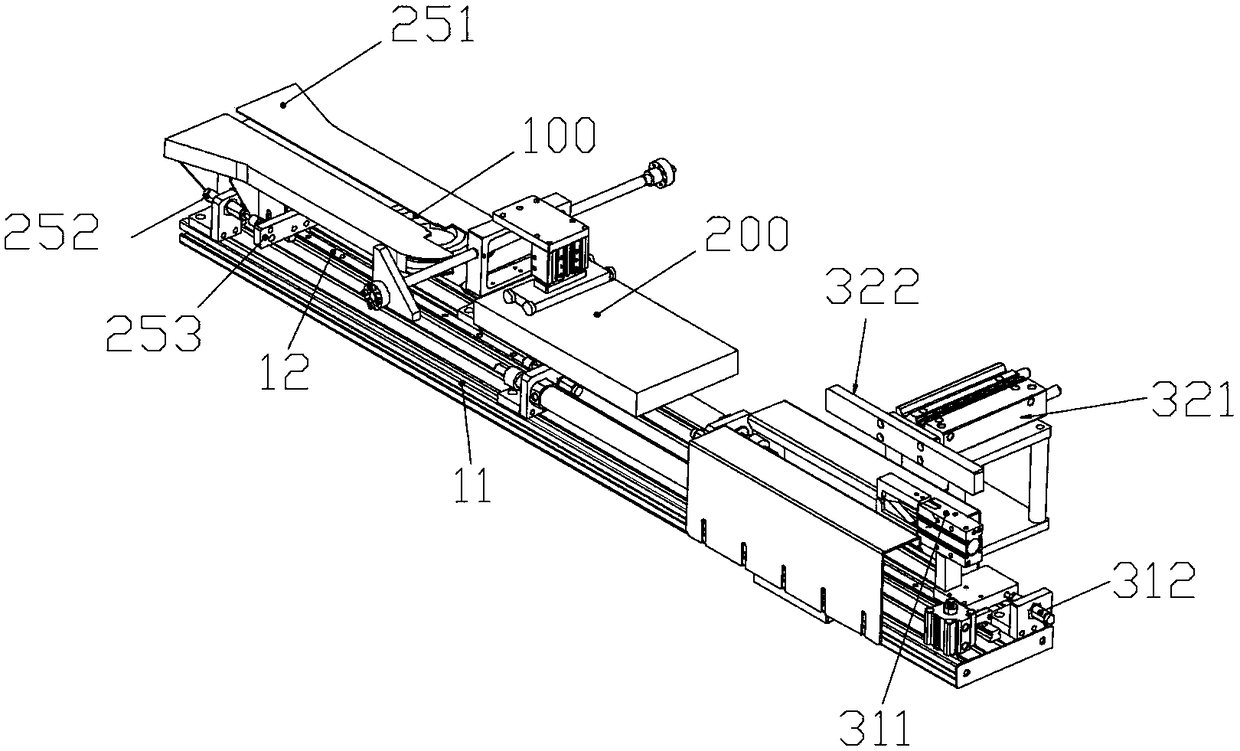

[0021] see figure 1 As shown, the present invention relates to an automatic winding and bagging mechanism for medical catheters, which is applied to medical catheter packaging equipment. The product output mechanism 5, the tube rolling mechanism 2, the bag making mechanism 4 and the material taking mechanism 3 are successively arranged on the frame 1, the bag making mechanism 4 is arranged on the rear and upper part of the tube rolling mechanism 2, and the material taking mechanism 3 is located between the bag-making mechanism 4 and the product output mechanism 5, and is used to put the bagged medical catheter 100 on the product output mechanism 5, and the product output mechanism 5 transports the bagged medical catheter 100 package to the next As for the station, the frame 1 is provided with a base 11, and the base 11 is provided with a slide rail 12.

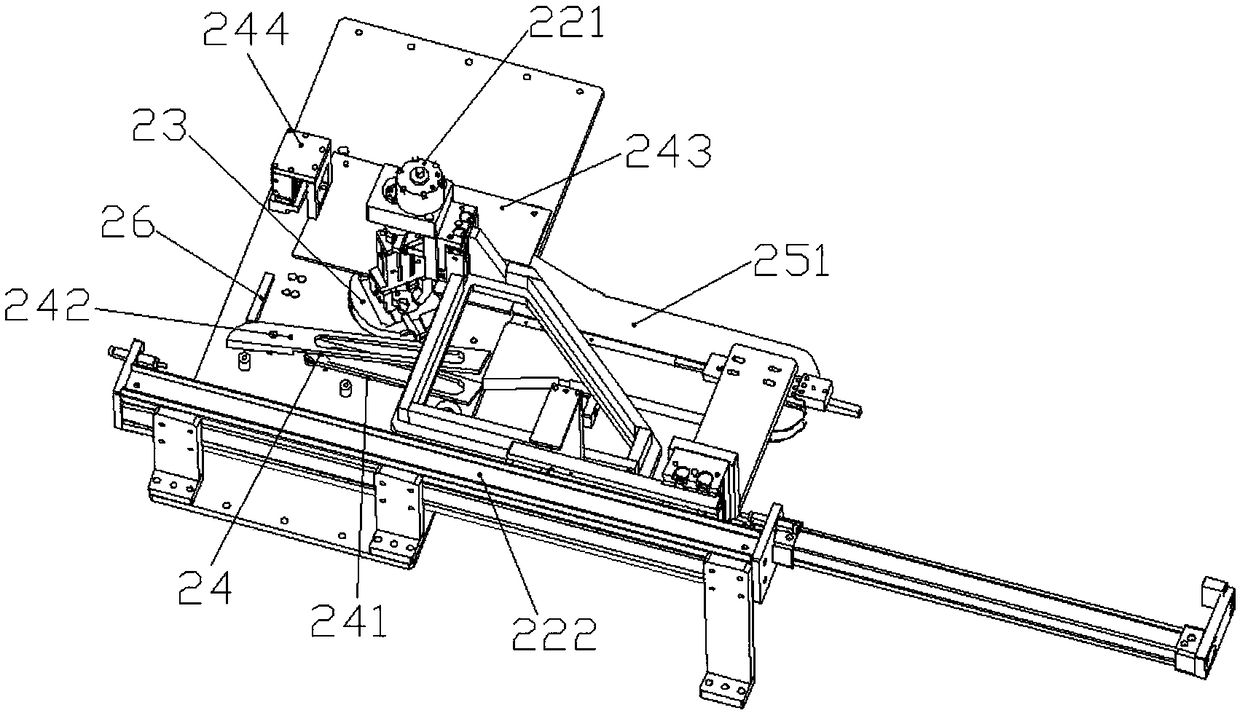

[0022] see figure 2 As shown, the tube rolling mechanism 2 includes a workbench 21, a clamping tube assembly 22, a reel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com