Lithium-enriching method and device for desalinizing lithium-poor brine

A brine and lithium-poor technology, applied in chemical instruments and methods, lithium compounds, energy input, etc., can solve the problems of difficulty in promotion and high energy consumption, and achieve the effects of easy collection, low energy consumption, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A lithium-deficient brine [Mg 2+ ]=104.5g / L, [Li + ]=0.19g / L, the ratio of magnesium to lithium is 550:1 by mass ratio.

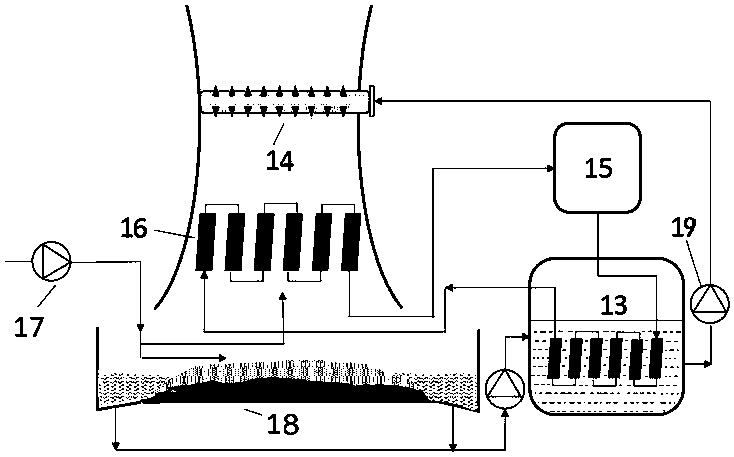

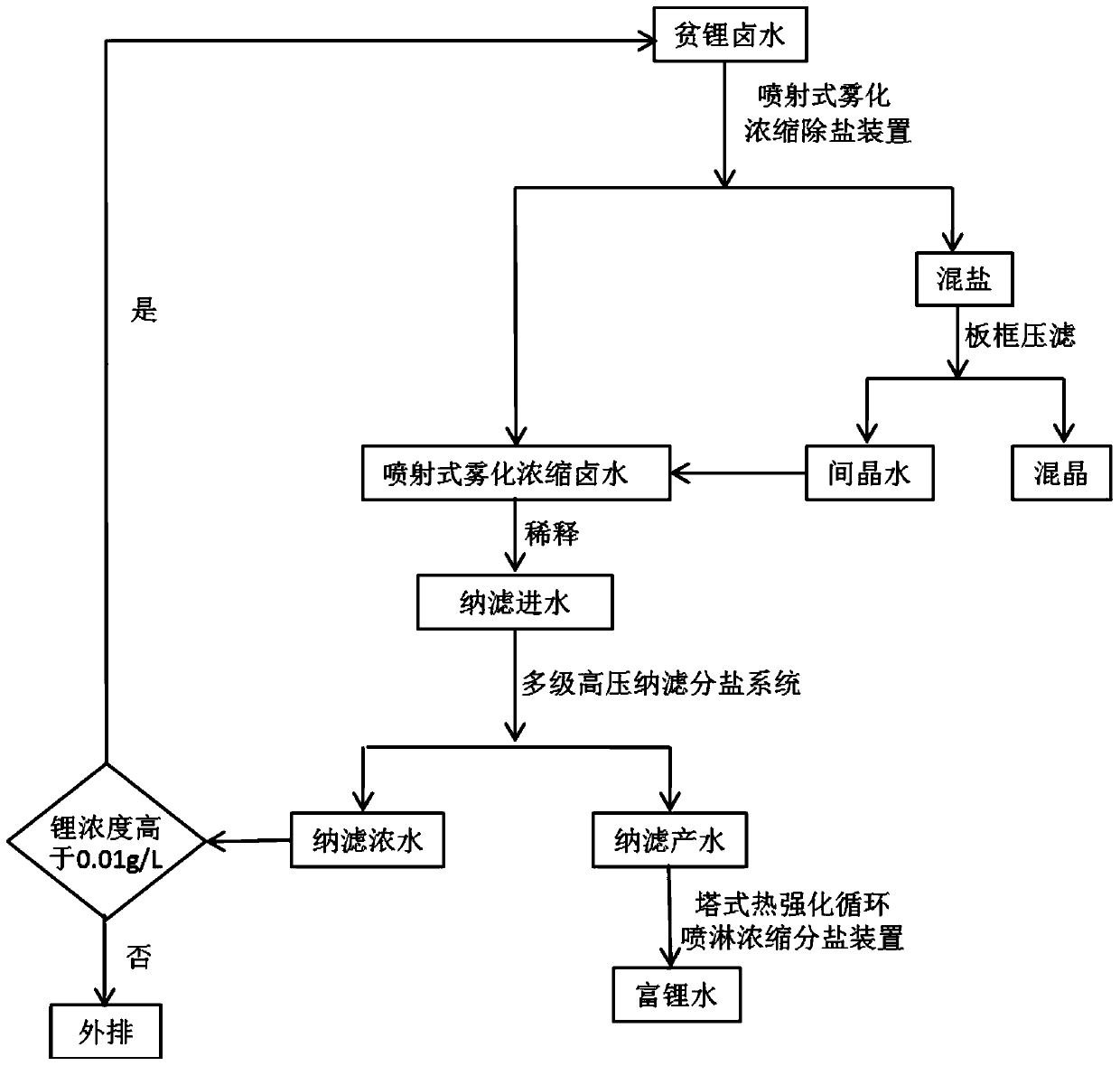

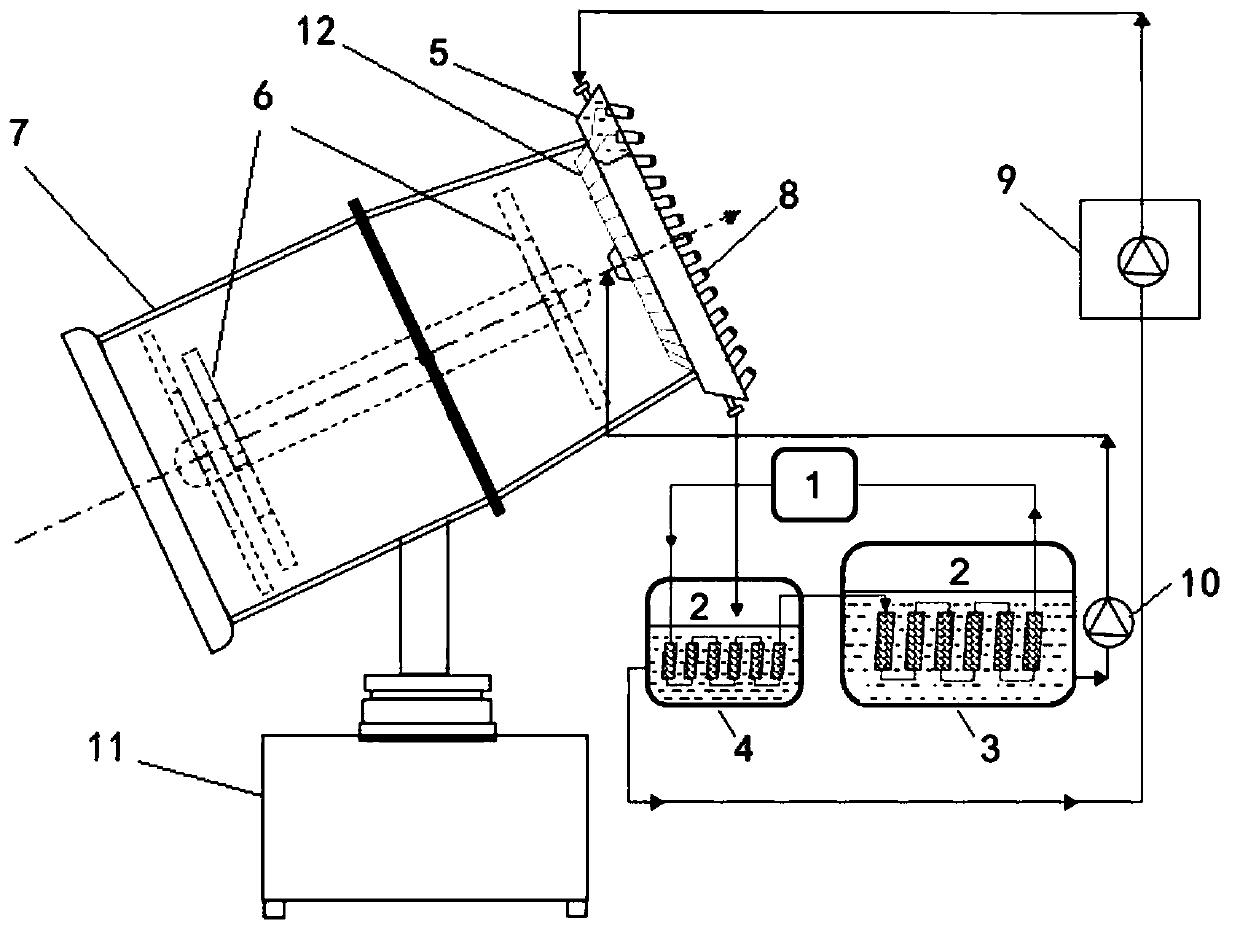

[0045] First, the lithium-poor brine is sprayed and evaporated through a spray-type atomization concentration and salt separation device, and the lithium-poor brine precipitates mixed crystals of potassium, sodium, and magnesium in a supersaturated state. Plate and frame filter press for solid-liquid separation. Lithium-rich intercrystalline water is collected. Jet atomized concentrated brine [Mg 2+ ]=110.3g / L, [Li + ]=0.89g / L.

[0046] The spray-type atomization concentration salt separation concentrated brine is diluted 1 times as nanofiltration raw water and enters the three-stage high-pressure nanofiltration circulation salt separation system to reduce salt, remove magnesium, and enrich lithium. The nanofiltration concentrated water at all levels is returned to the feed of the jet atomization concentration and salt separation device. Nanof...

Embodiment 2

[0049] A lithium-deficient brine [Mg 2+ ]=76.88g / L, [Li + ]=0.083g / L, the ratio of magnesium to lithium is 927:1 by mass ratio.

[0050] First, the lithium-poor brine is sprayed and evaporated through a spray-type atomization concentration and salt separation device, and the lithium-poor brine precipitates mixed crystals of potassium, sodium, and magnesium in a supersaturated state. Plate and frame filter press for solid-liquid separation. Collect lithium-rich intercrystalline water, that is, jet atomized concentrated brine. Jet atomization concentrated brine [Mg 2+ ]=113.8g / L, [Li + ]=0.32g / L.

[0051] Jet atomized concentrated brine is diluted 1 times as nanofiltration raw water and enters the five-stage high-pressure nanofiltration circulation salt separation system to reduce salt, remove magnesium, and enrich lithium. The nanofiltration concentrated water at all levels is discharged. Nanofiltration product water [Mg 2+ ]=5.29g / L, [Li + ]=0.35g / L.

[0052] The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com