Method for preparing calcium chloride from fluidized bed fly ash

A fly ash and fluidized bed technology, applied in the chemical field, can solve the problems of high raw material cost and low product benefit, and achieve the effects of low corrosiveness, easy operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

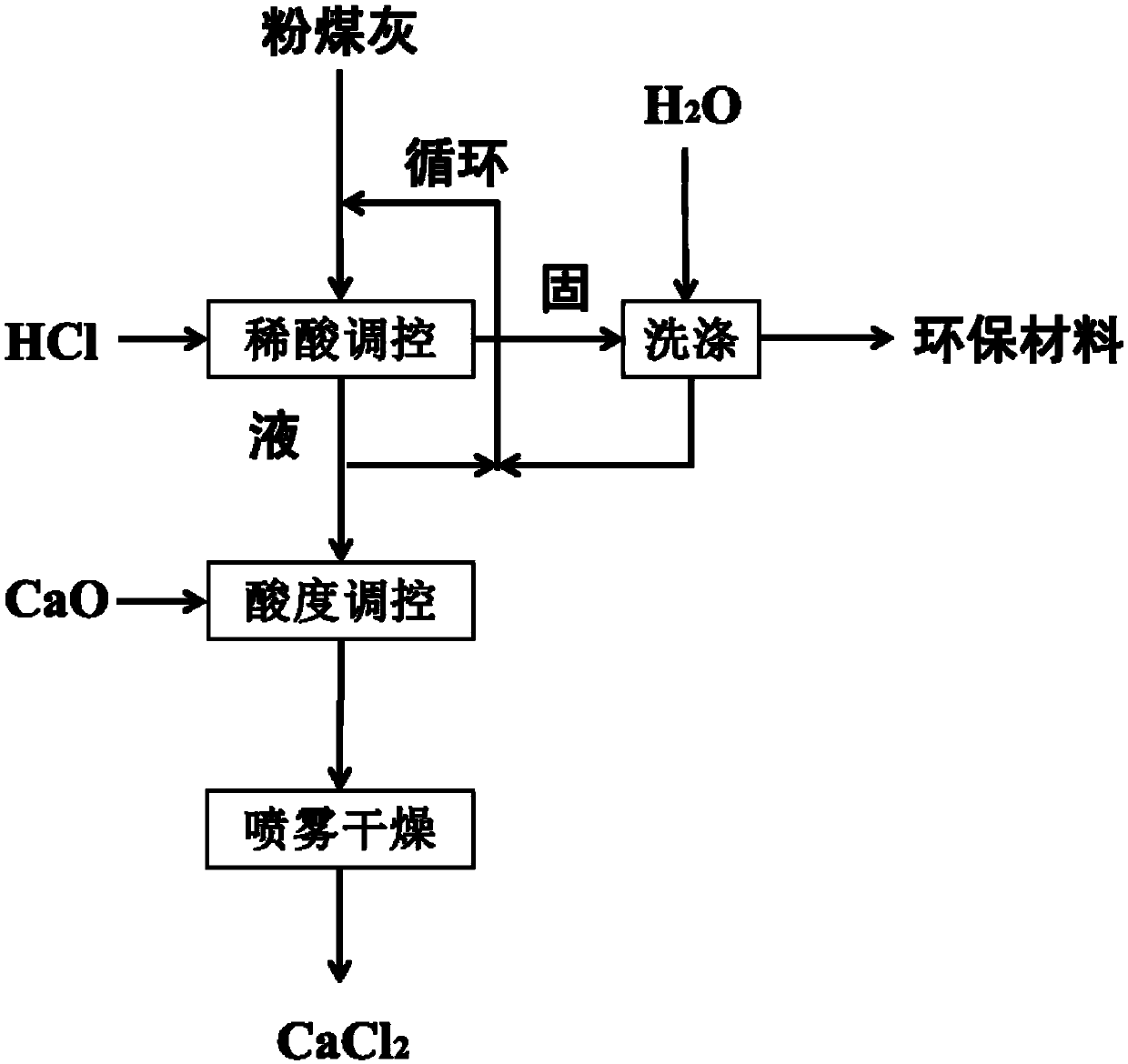

[0052] A kind of method utilizing fluidized bed fly ash to prepare calcium chloride, flow chart sees figure 1 , including the following steps:

[0053] Dilute acid decalcification: use fly ash and water to mix according to the liquid-solid ratio of 4:1, and add hydrochloric acid with a concentration of 350g / L to it, adjust the pH to 3.5, the reaction temperature is 60°C, the reaction time is 90min, and the rotation speed is 350r / min; after the reaction is over, the filtrate is obtained after solid-liquid separation and washing, and the leached residue is washed at a temperature of 80°C with a liquid-solid ratio of 1.5:1;

[0054] Circulation process: mix the above-mentioned filtrate and fly ash raw materials according to the above-mentioned ratio, and carry out cyclic enrichment according to the conditions of the dilute acid decalcification process. After 6 cycles, filter to obtain a calcium-enriched solution;

[0055] System regulation: add calcium oxide to the calcium-enric...

Embodiment 2

[0058] A kind of method utilizing fluidized bed fly ash to prepare calcium chloride comprises the steps:

[0059] Dilute acid decalcification: use fly ash and water to mix according to the liquid-solid ratio of 3:1, and add hydrochloric acid with a concentration of 300g / L to it, adjust the pH to 3, the reaction temperature is 55°C, the reaction time is 60min, and the rotation speed is 350r / min; after the reaction is over, the filtrate is obtained after solid-liquid separation and washing, and the leached residue is washed with water at a temperature of 25°C at a liquid-solid ratio of 0.5:1 for later use;

[0060] Circulation process: mix the above-mentioned filtrate with the fly ash raw material according to the above-mentioned ratio, and carry out cyclic enrichment according to the conditions of the dilute acid decalcification process, and after 5 cycles, filter to obtain a calcium-enriched solution;

[0061] System regulation: add calcium oxide to the calcium-enriched filtra...

Embodiment 3

[0064] A kind of method utilizing fluidized bed fly ash to prepare calcium chloride comprises the steps:

[0065] Dilute acid decalcification: use fly ash and water to mix according to the liquid-solid ratio of 5:1, and add hydrochloric acid with a concentration of 250g / L to it, adjust the pH to 4, the reaction temperature is 75°C, the reaction time is 120min, and the rotation speed is 350r / min; After the reaction is over, the filtrate is obtained after solid-liquid separation and washing, and the leached residue is washed at a temperature of 100°C by adding water at a liquid-solid ratio of 2:1 for later use;

[0066] Circulation process: mix the above-mentioned filtrate and fly ash raw materials according to the above-mentioned ratio, and carry out cyclic enrichment according to the conditions of the dilute acid decalcification process. After 6 cycles, filter to obtain a calcium-enriched solution;

[0067] System regulation: add calcium oxide to the calcium-enriched filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com