A method for combined removal of impurities by separation and smelting of waste circuit board copper powder

A combined technology of waste circuit boards, separation and smelting, applied in chemical instruments and methods, wet separation, improvement of process efficiency, etc., can solve problems affecting the stability of the copper smelting system, waste of valuable metal resources, and affecting the quality of cathode copper, etc. , to achieve the effects of low production cost, high enrichment, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

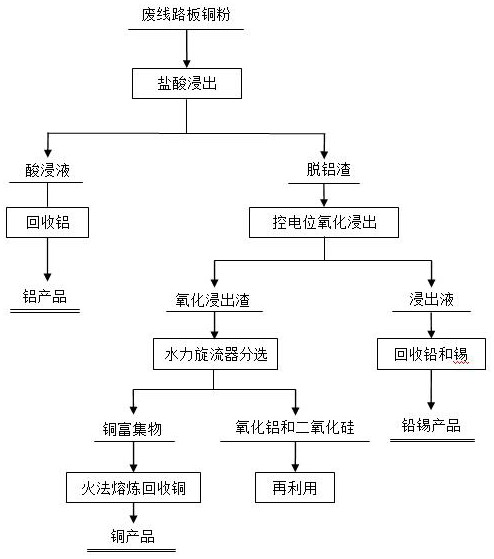

Image

Examples

Embodiment 1

[0026] The waste circuit board copper powder produced by the waste circuit board crushing and sorting process of a domestic enterprise, its main components are (%): Cu44.6, Al2.5, Sn9.2, Pb5.1, Au20g / t and Ag700g / t. Both hydrochloric acid and hydrogen peroxide are reagents of analytical grade, of which the mass percentage of hydrochloric acid is not less than 36.0%, and the mass percentage of hydrogen peroxide is not less than 30%.

[0027] Prepare a hydrochloric acid solution with a molar concentration of 1.5mol / L, add waste circuit board copper powder according to the ratio of liquid-solid ratio (the ratio of solution volume L to solid weight Kg) 5:1, and use a constant temperature magnetic stirring water bath for heating and stirring. Control the reaction temperature at 80°C and the reaction time for 2 hours. After the reaction is completed, cool to room temperature and filter. The leaching rate of aluminum is greater than 97.0%. Prepare a hydrochloric acid solution with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com