High-low groove type oil-stain floating collection system

A collection system and low tank technology, applied in the field of oil pollution floating collection in high and low tanks, can solve the problems of low oil-water separation efficiency, polluted ground environment, high investment cost, easy later management and maintenance, improved oil-water separation rate, stable operation reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

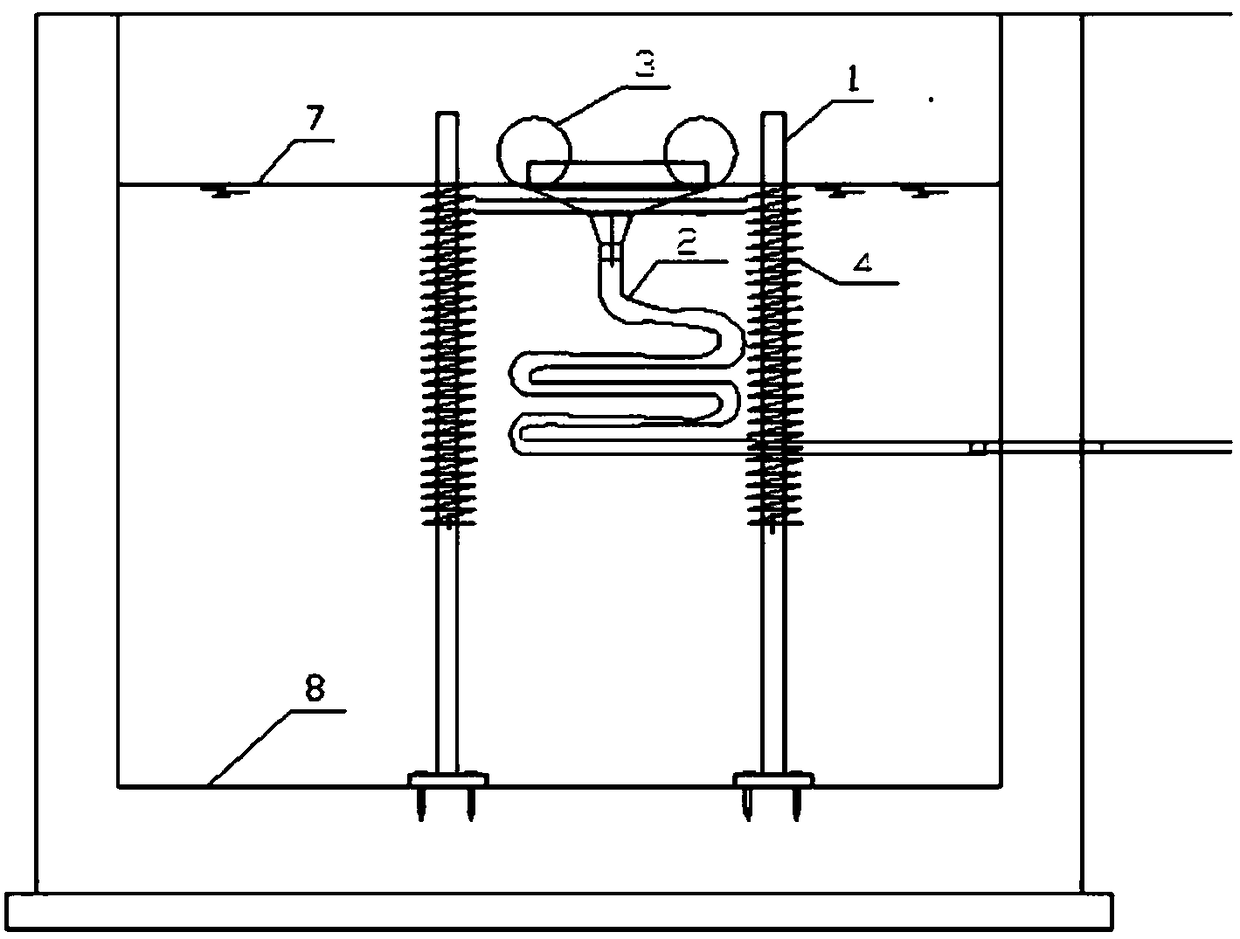

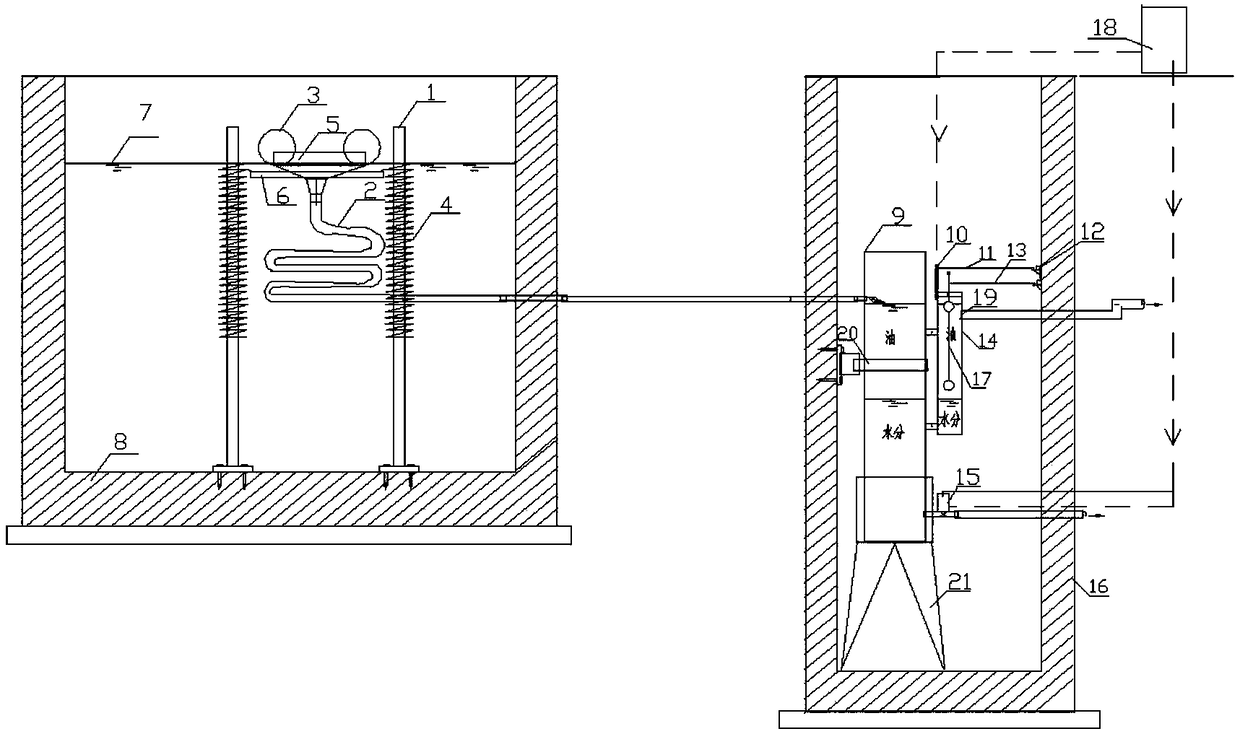

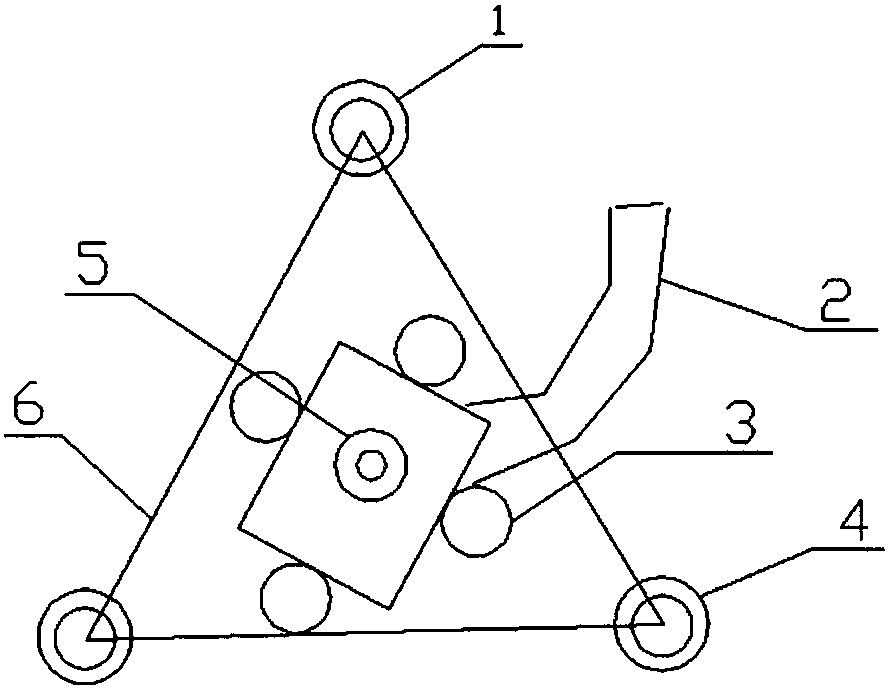

[0024] Such as figure 1 A high and low trough oil floating collection system shown mainly includes a high trough structure and a low trough structure. Such as figure 2 The high groove structure shown mainly includes a high groove base 8, a limiting column 1 and an oil collection conduit 2, the limiting column 1 is arranged in the inner cavity of the high groove base 8, and a flexible spring 4 is set on the upper part of the limiting column 1 (the diameter of the flexible spring 4 is about 20 mm larger than the diameter of the limit column 1), the lower end of the flexible spring 4 is fixedly connected with the limit column 1; the upper end of the flexible spring 4 can move up and down along the limit column 1, and connect with the limit bracket 6 connected; the upper part of the oil collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com