Intelligent kitchen waste treatment equipment

A technology of food waste and treatment equipment, which is applied in the field of intelligent food waste treatment equipment, can solve the problems of inaccurate temperature detection, lack of diversified adjustment of air intake pipes and air outlet pipes, etc., and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

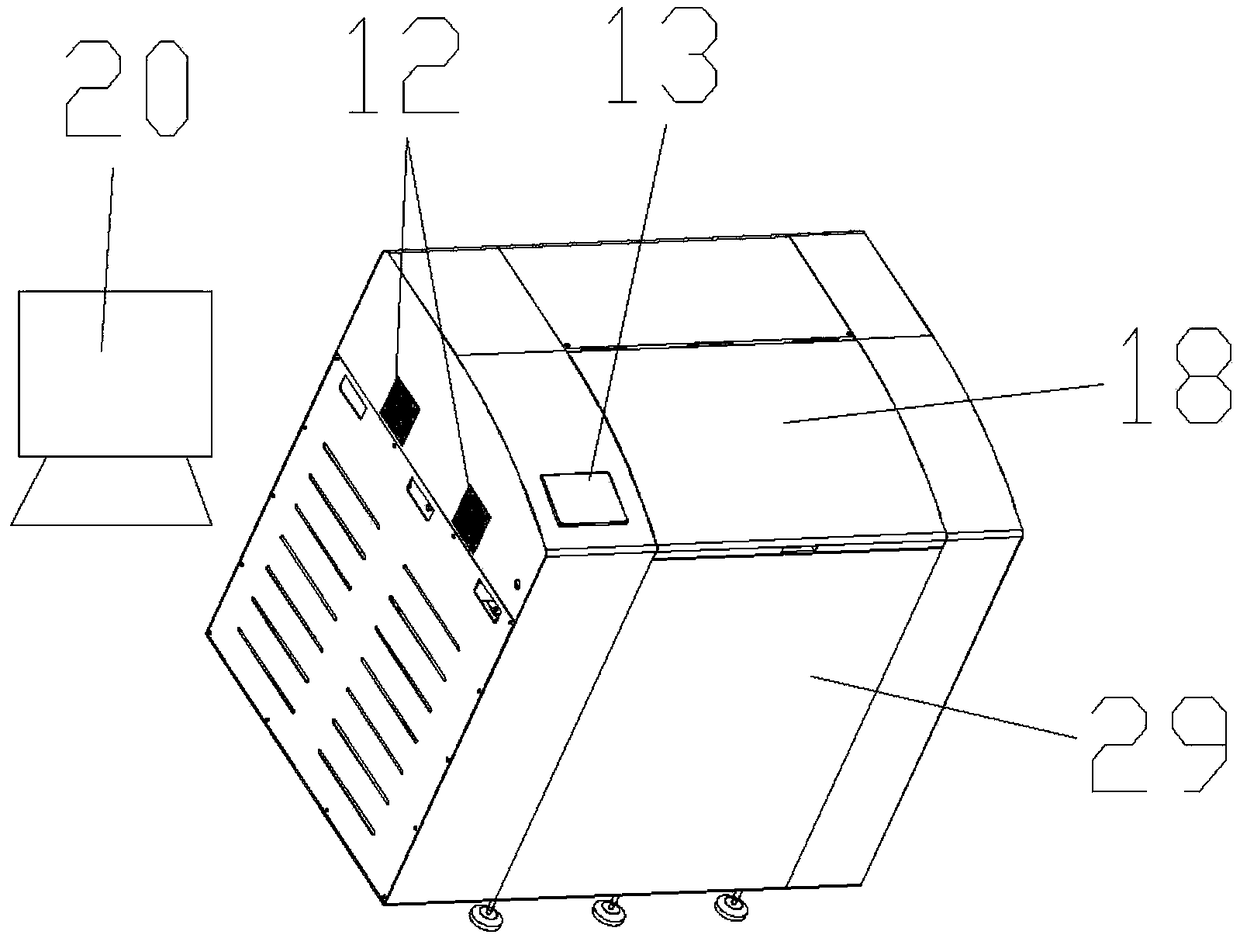

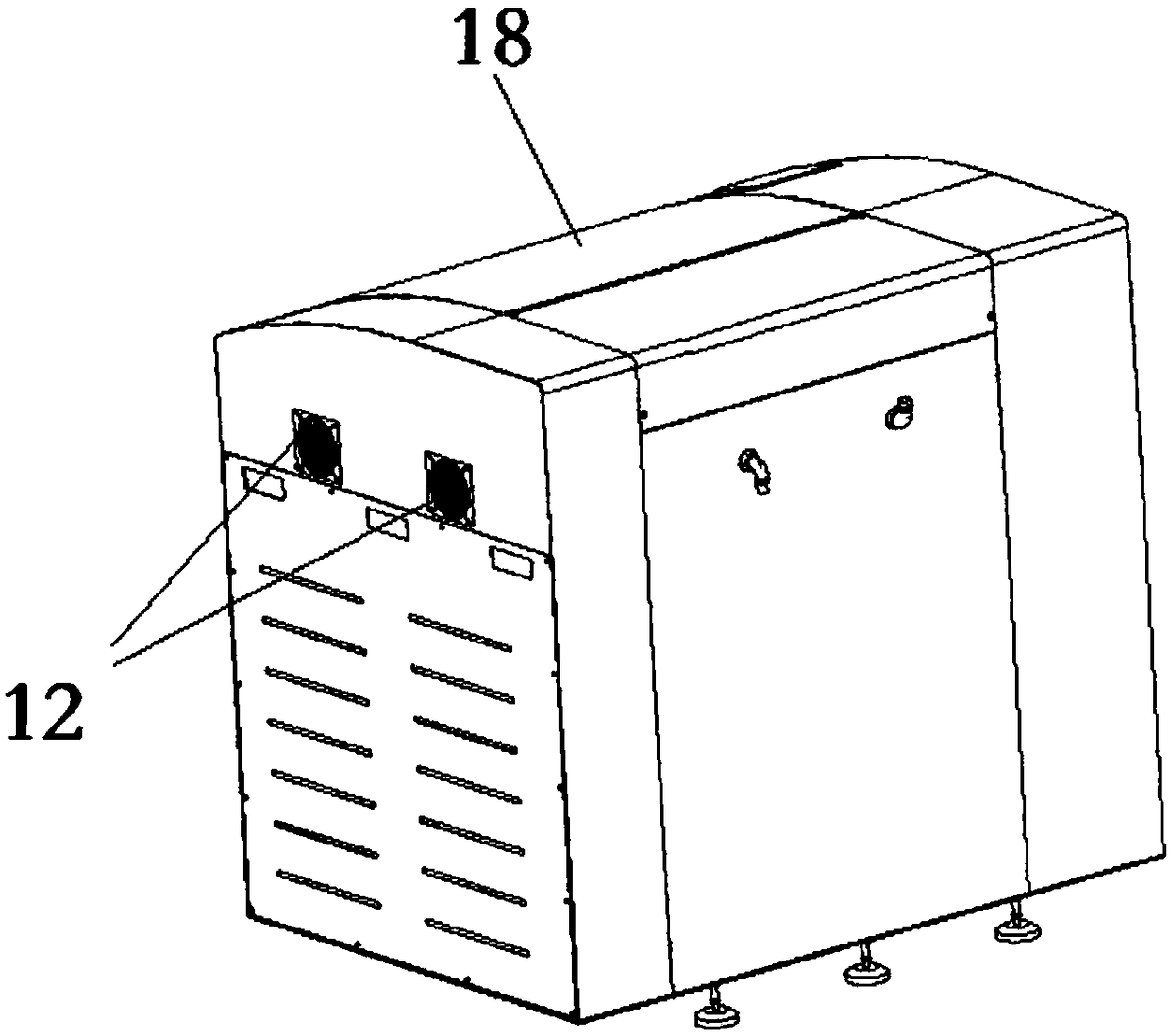

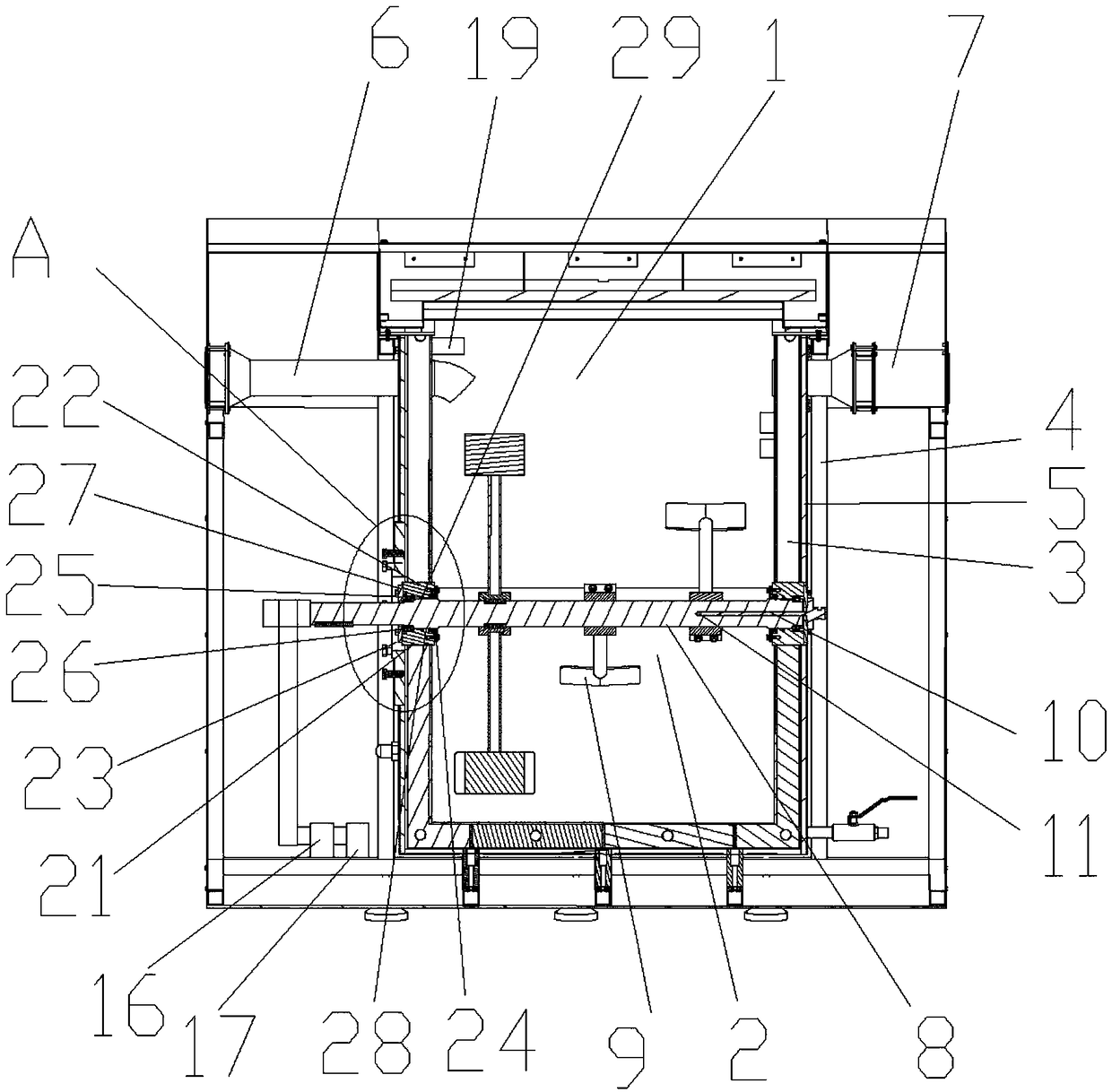

[0025] An intelligent kitchen waste treatment device, comprising a fermentation chamber 1 and a stirring device 2 arranged in the fermentation chamber 1, the fermentation chamber 1 includes an inner tank 3 and an outer tank 4, and the inner tank 3 and the outer tank 4 As an insulated water tank 5, at least two air inlet pipelines 6 and two air outlet pipelines 7 are provided on the fermentation chamber 1, and the stirring device 2 includes a main shaft 8 transversely penetrating the fermentation chamber 1 and a main shaft 8 arranged on the main shaft 8 Stirring paddle 9, the rotating speed of stirring device 2 is 10-14rpm in the present embodiment, also comprises the first temperature sensor 10 that is arranged in the main shaft 8 of stirring device 2, and the probe end 11 of described first temperature sensor 10 is positioned at main shaft 8 inside, the other end protrudes out of the main shaft 8, and fans 12 are arranged in each air inlet pipeline 6 and each outlet pipeline 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com