Ultra-high pressure balanced load balancing valve and method thereof

An ultra-high pressure and balanced technology, applied in the field of hydraulic control valves, can solve the problems of increased load of the jacking cylinder, partial load, structural damage of the workpiece, etc., and achieve the effect of increasing the load capacity and improving the economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

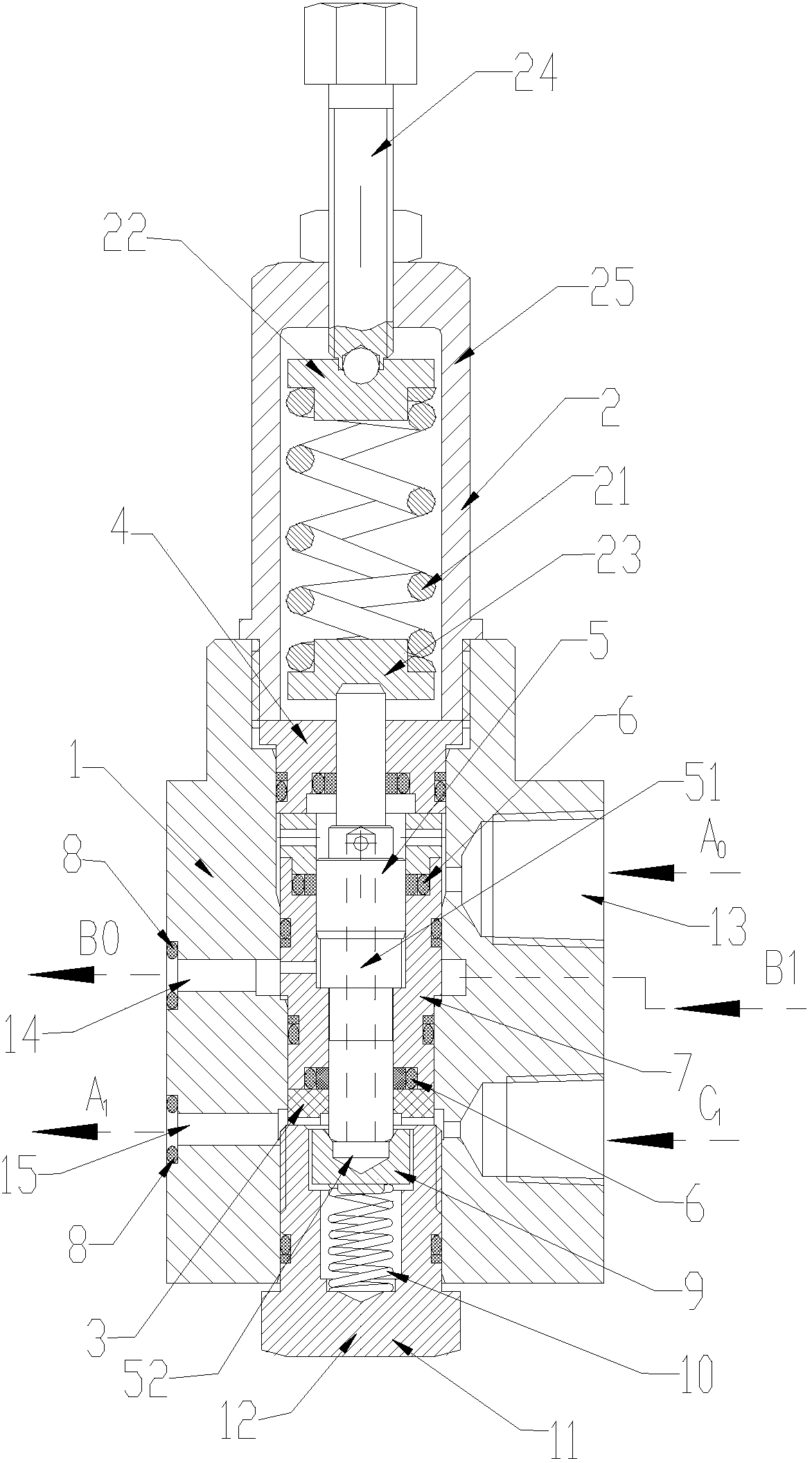

[0036] Such as figure 1 The illustrated ultra-high pressure balanced load equalizing valve of the present invention includes a valve cavity arranged in the valve body 1 and communicated with the outside up and down. The valve cavity is preferably cylindrical as a whole, and the valve cavity is fixedly arranged There is a valve sleeve 7, and a spool 5 is movable inside the valve sleeve 7, and the spool 5 can move up and down sealed in the valve sleeve 7, that is, to ensure sealing and move up and down, and the spool 5 Both ends are respectively sleeved with an upper sealing seat 4 and a lower sealing seat 3, the valve core 5 can protrude from the upper sealing seat 4 and the lower sealing seat 3, and its contact surface is sealed and liquid-tight, the upper and lower parts of the valve cavity The ends are respectively sealed with a pressure regulating spring device 2 and a conical valve seat spring device 11. It is used to adjust the pressure of the top pressure valve core 5, ...

Embodiment 2

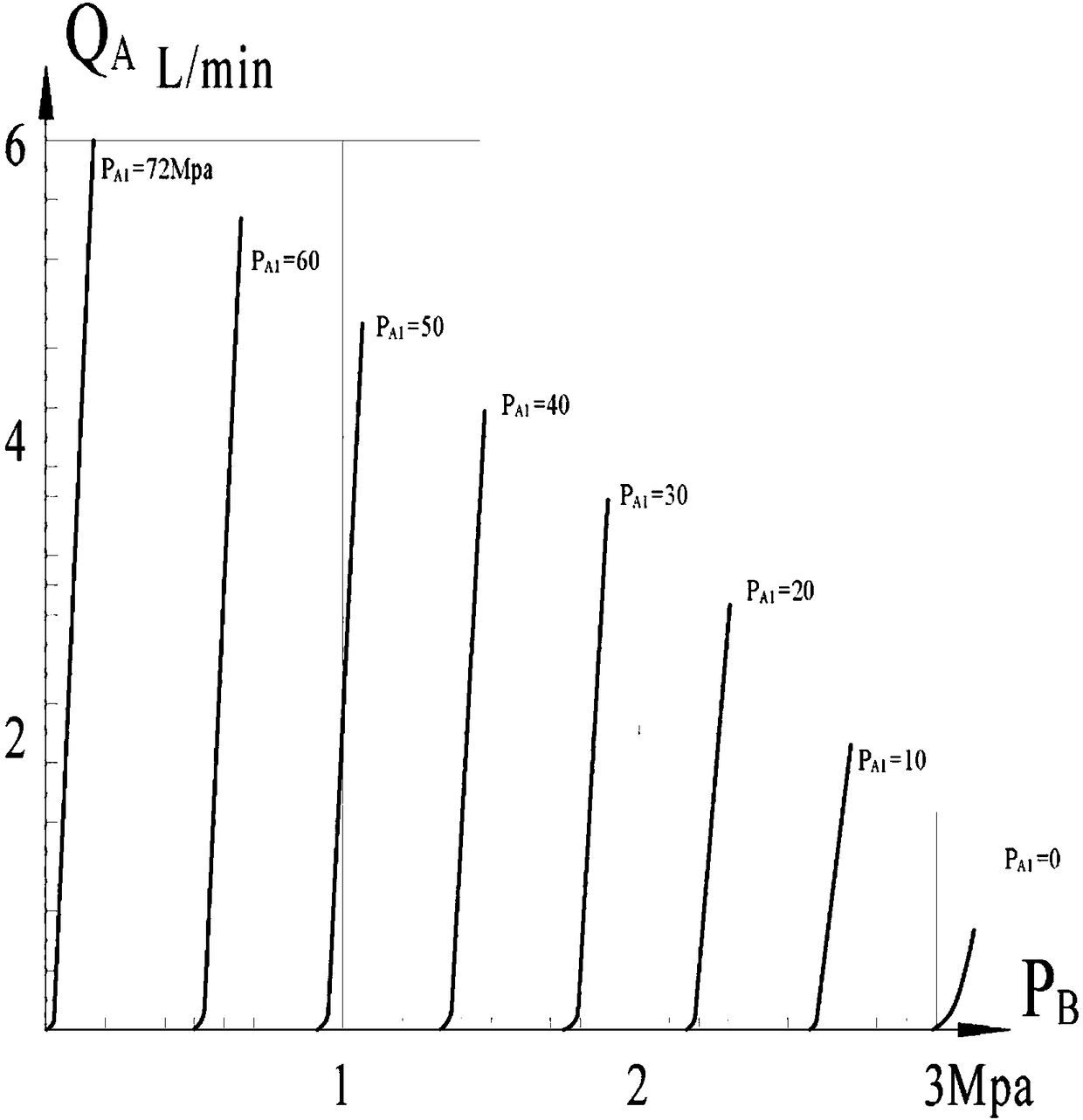

[0043] On the basis of the ultra-high pressure balanced load equalizing valve described in Embodiment 1, the pressure regulating spring device 2 includes a spring cover 25 sealingly arranged on the upper end of the valve cavity, and the spring cover 25 is provided with a pressure regulating spring 21 and the The upper spring seat 22 and the lower spring seat 23 at the two ends of the pressure regulating spring 21, the lower spring seat 23 is pressed against the upper end of the valve core 5, and the upper end of the upper spring seat 22 is provided with an adjusting screw 24, which can be rotated Turn the adjustment screw 24 to adjust the pressure value of the pressure regulating spring 21 to provide different pressure value needs. In the present embodiment, 72 is the set pressure (Mpa) of the ultra-high pressure balance load balancing valve. Therefore, the ultra-high pressure balance equalization The opening condition of the carrier valve can be approximately expressed as: P ...

Embodiment 3

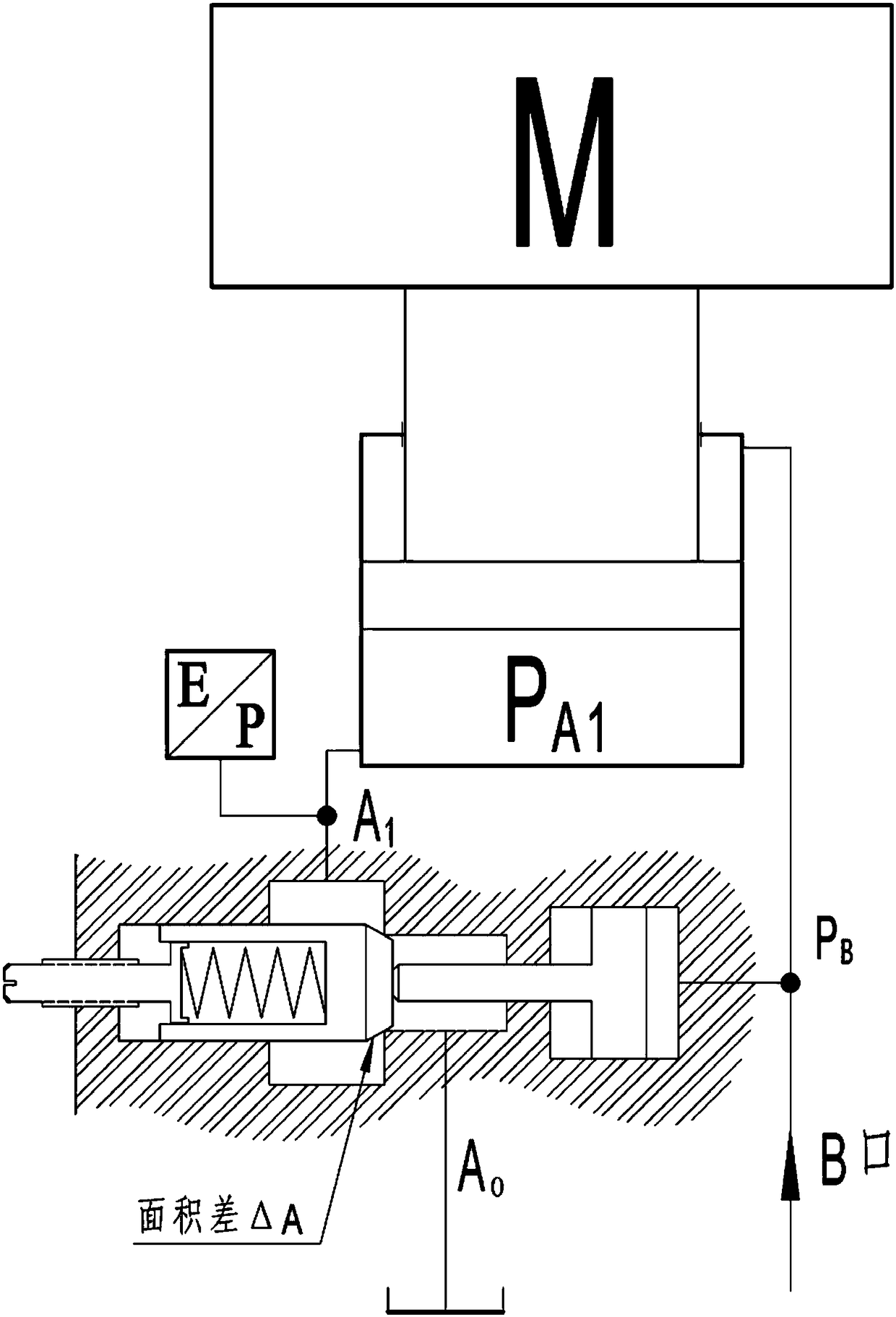

[0052] A balanced load balancing method using the above-mentioned ultra-high pressure balanced load balancing valve, comprising:

[0053] S1: Oil inlet jacking state, such as Figure 4 As shown: Oil flows in from the upper oil port A0, passes through the channel 51 of the valve core 5, pushes the conical valve seat spring device 11, and flows into the lower oil port A1;

[0054] S2: proportional control landing state, such as Figure 6 As shown: oil enters from the pilot control port B0, the black part in the figure is the oil, push the valve core 5 to adjust upward, overcome the pressure regulating spring device 2, and make the valve core 5 and the conical valve seat spring device 11 produce a proportional force The opening makes the pressure oil from the lower oil port A1 flow into the upper oil port A0 proportionally. As the control oil pressure of the pilot control port B0 increases, the proportional opening becomes larger, and the pressure oil from the lower oil port A1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com