Automatic plate weight-balancing mechanism for computer to plate

A plate-making machine and counterweight technology, which is applied in printing plate preparation, printing, and balancing rotating bodies, etc., can solve the problems of low counterweight accuracy, troublesome counterweight adjustment, time-consuming and labor-intensive operation, etc., and achieve simple structure and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

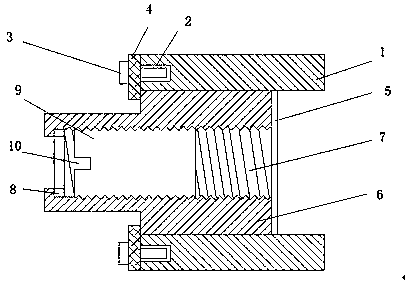

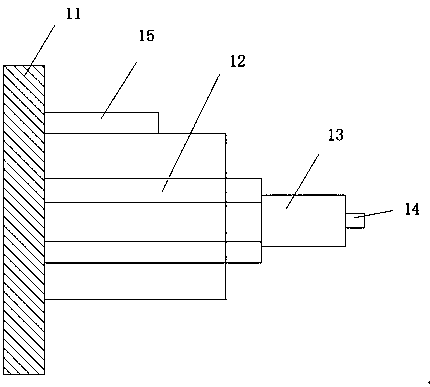

[0019] Such as Figure 1-2 As shown, the present invention provides a plate automatic counterweight mechanism for a direct plate-making machine, including a drum 1 and a mounting plate 11, a screw hole 2 is provided at the left end of the drum 1, and a retaining ring 4 is installed at the left end of the screw hole 2 through a fixing bolt 3. 1. There is a counterweight groove 5 in the middle, and a counterweight 6 is connected to one side of the counterweight trough 5. The middle part of the counterweight 6 is provided with a threaded hole 7. The left end of the threaded hole 7 is connected to a distance sensor 8, and a counterweight is installed in the threaded hole 7. 9. A groove 10 is provided at the left end of the counterweight 9, a cylinder 12 is installed in the middle of the mounting plate 11, and the right end of the cylinder 12 is connected to the adjusting rod 13, and the right end of the adjusting rod 13 is provided with a convex strip 14, and the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com