Liquid level measurement device for flotation machine

A liquid level measurement device and flotation machine technology, which is applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc., can solve the problem of inability to timely and accurately control the liquid level, large adjustment errors, and large fluctuations in the liquid level Large and other problems, to achieve the effect of novel structure, long service life, and improve precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

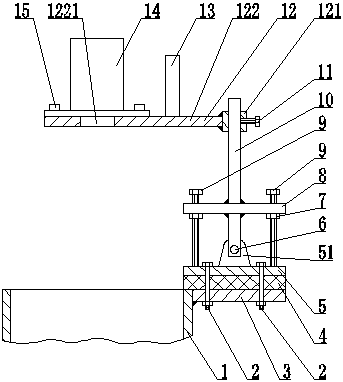

[0007] see figure 1 , the present invention includes a filter cartridge 1, a connecting plate 3, a shock absorbing rubber 4, a base 5, a rotating shaft 6, a positioning plate 8, a sliding rod 10, a sliding seat set screw 11, a sliding seat 12, a take-up post 13, a laser ranging Instrument 14, several base bolts 2, several lock nuts 7, several adjusting screws 9 and several hexagon socket head cap screws 15, the upper surface of the base 5 is welded with ear plates 51, and the sliding seat 12 includes sliding Cover 121 and flat plate 122, the left part of the flat plate 122 is provided with a circular hole 1221, the connecting plate 3 is welded on the right side of the filter cartridge 1, and the damping rubber 4 is clamped on the connecting plate by the base bolt 2 3 and the base 5, the slide bar 10 is connected with the ear plate 51 through the rotating shaft 6, the positioning plate 8 is welded on the slide bar 10, the adjusting screw 9 is mounted on the positioning plate 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com