Integrated modular small pressurized water reactor of steam generator

A steam generator and modular technology, which is applied in the field of reactor design, can solve the problems of pressure vessel failure increase, etc., and achieve the effects of reducing openings, improving thermal efficiency, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

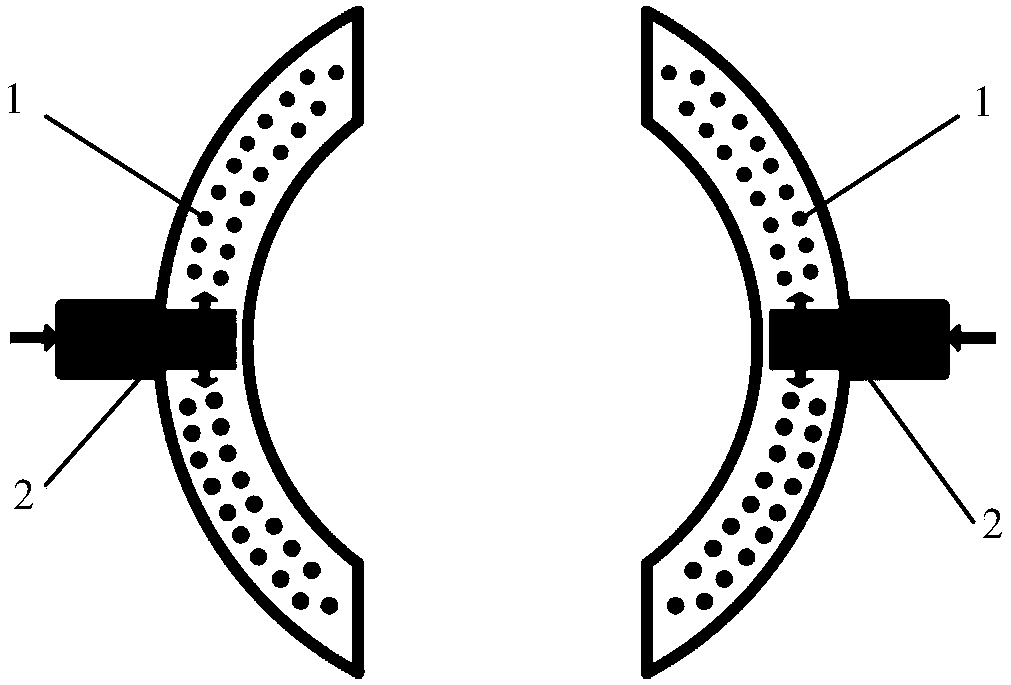

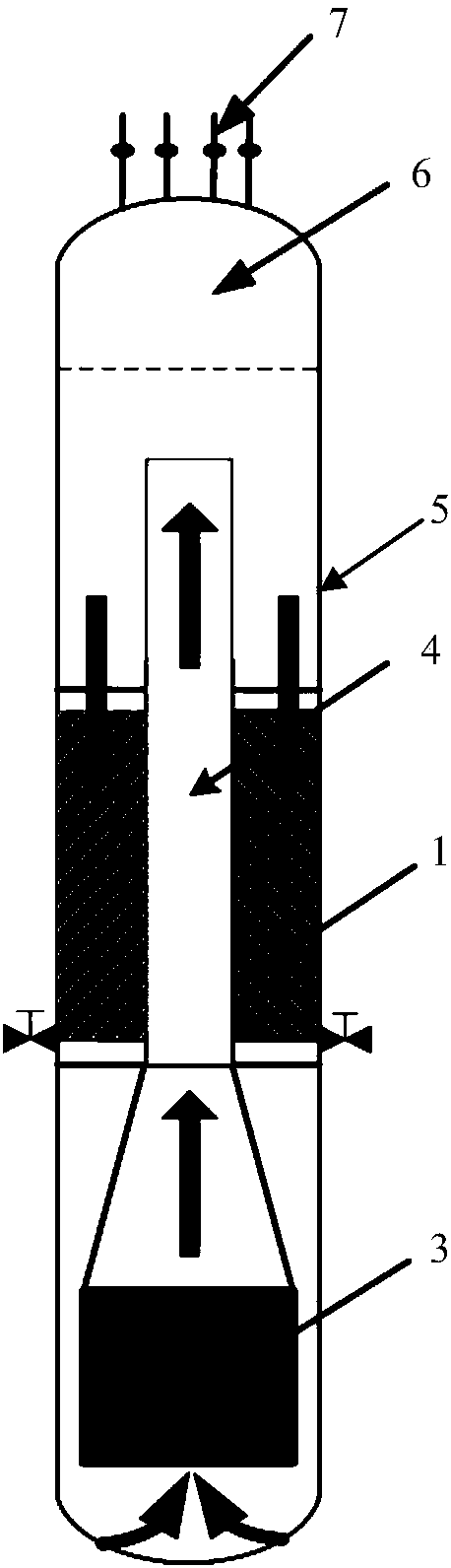

[0019] This embodiment adopts the double helix structure steam generator heat transfer tube with coaxial double inlets, such as figure 1 As shown, the heat transfer tube of the double helix structure is provided with two symmetrical feed water inlets, and each feed water inlet is respectively connected to a group of heat transfer tubes through a feed water header. Its design can make full use of the annular space from the rising section of the core to the inner wall of the pressure vessel, integrate the steam generator in the reactor pressure vessel, dilute the concept of the steam generator, and design it as a casing pressure vessel. Through material innovation and equipment innovation, improving the manufacturing precision of pressure vessels and steam generators can promote the modularization, standardization and batch development of small pressurized water reactors.

[0020] The innovative design of the present invention mainly includes: a double helical tube type direct-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com