Control method and device of electronic cigarette as well as electronic cigarette

A control method and technology of electronic cigarettes, which are applied in the fields of tobacco, smoker’s supplies, applications, etc., can solve problems such as inability to produce smoke, affect user’s taste, and waste, so as to avoid scorching or not being atomized, and improve the effective utilization rate , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

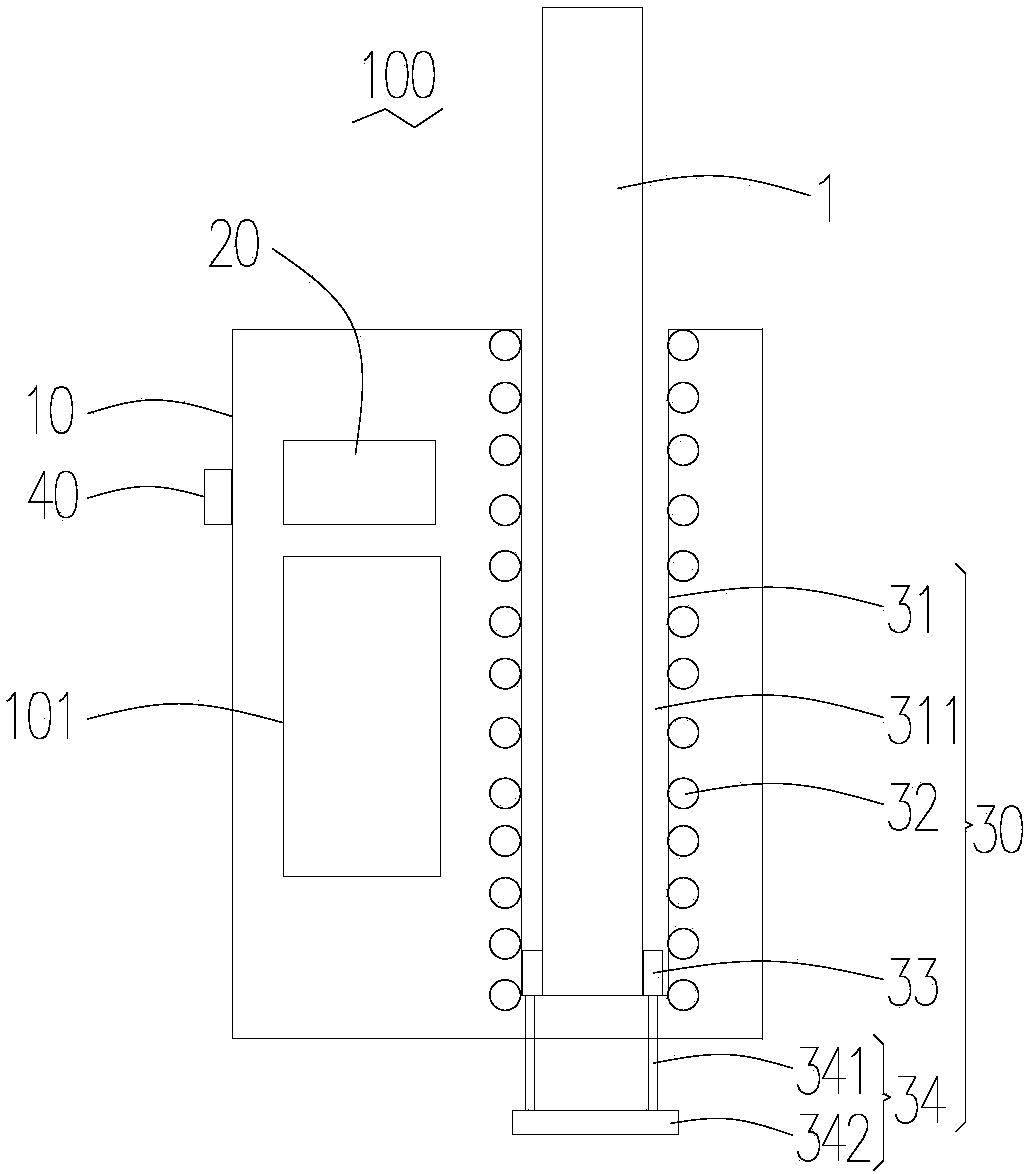

[0065] see figure 1 Embodiment 1 of the present invention provides an electronic cigarette 100. The electronic cigarette 100 includes an atomization assembly 30 and a power supply device 101 electrically connected to the atomization assembly 30. When in use, the power supply device 101 electrically drives the atomization assembly 30 to work. , so that the atomizing assembly 30 heats the tobacco product 1 to generate smoke for use by the user.

[0066] The electronic cigarette 100 also includes a housing 10 . The atomization assembly 30 is installed on the shell 10, the cigarette key 40 is installed on the shell 10, the controller 20 is arranged in the shell 10, the controller 20 is electrically connected with the cigarette key 40, the power supply 101 and the atomization assembly 30, The power supply unit 101 is provided inside the casing 10 . It can be understood that, in other unshown embodiments, at least one of the controller 20 , the cigarette button 40 and the power su...

Embodiment 2

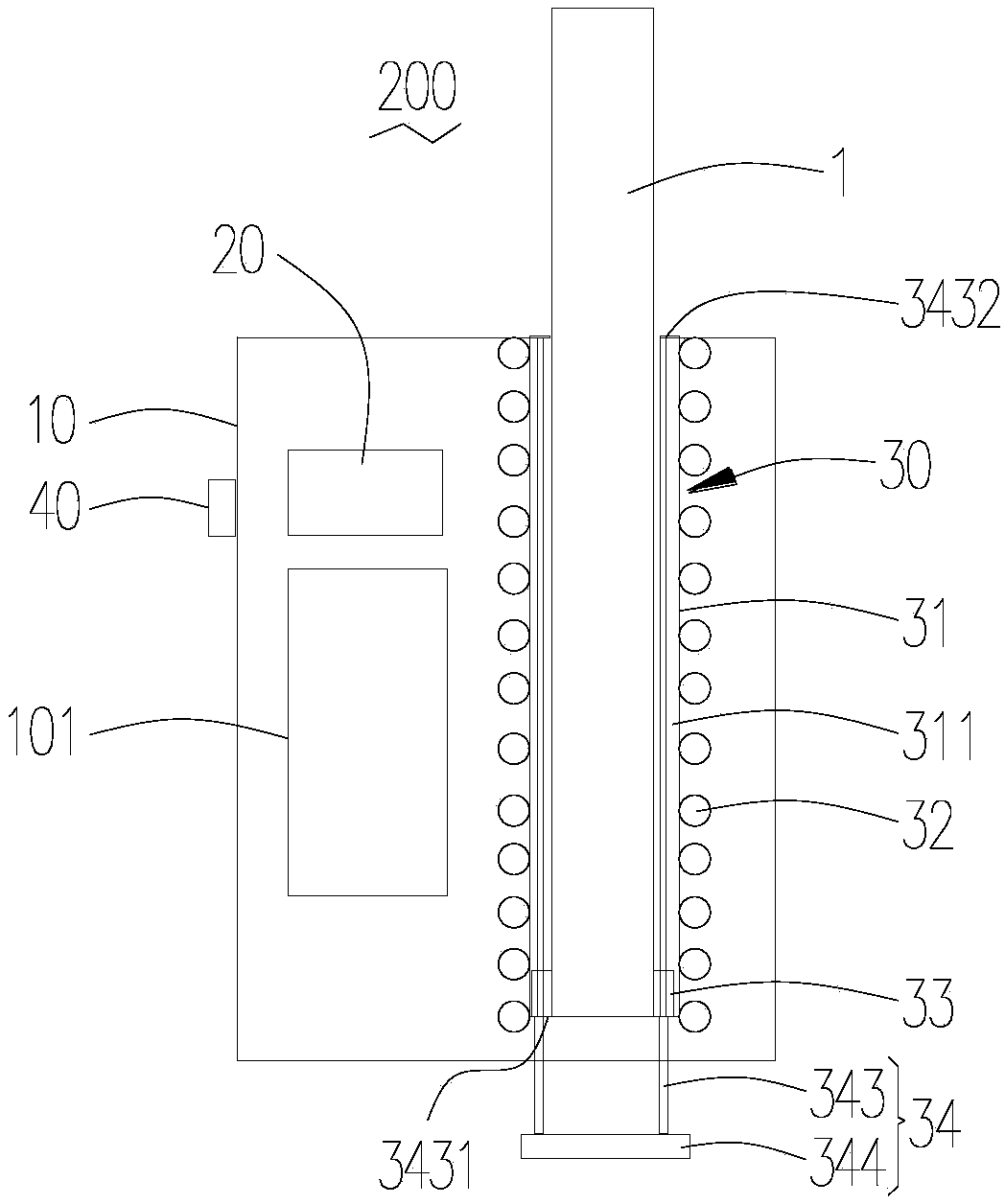

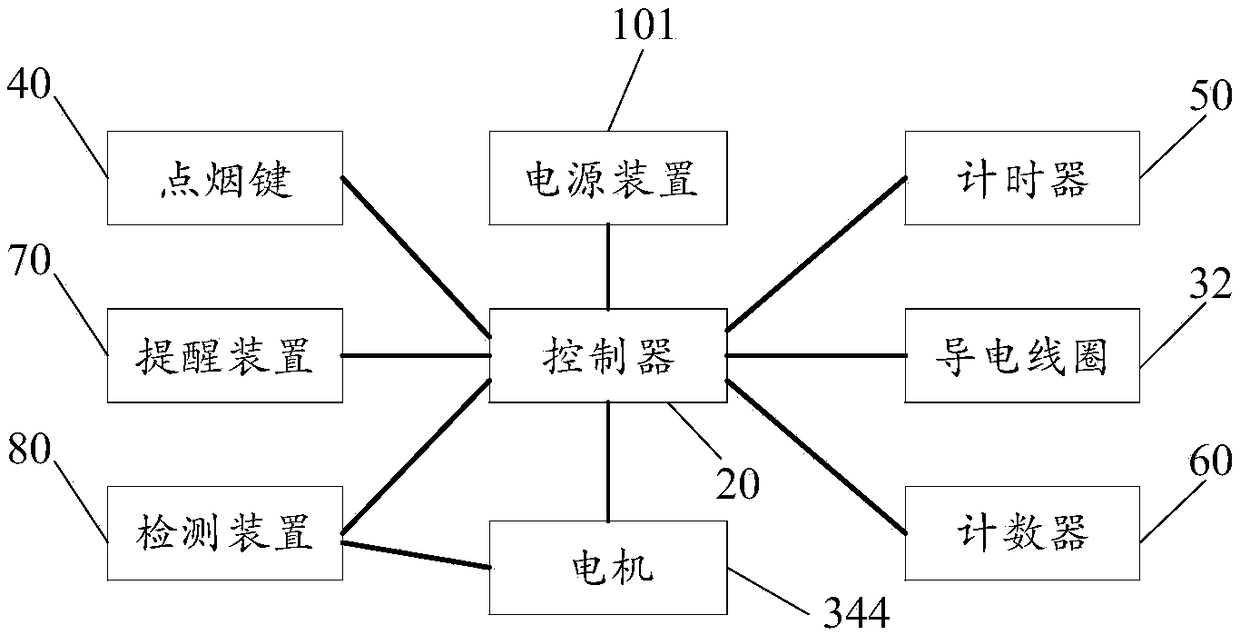

[0081] see figure 2 , image 3 The difference between the electronic cigarette 200 provided by the second embodiment of the present invention and the electronic cigarette 100 provided by the first embodiment is that the driving mechanism 34 in the atomization assembly 30 of the second embodiment drives the heating element 33 to move in an automatic manner, Specifically, the electronic cigarette 200 also includes a reminder device 70, a timer 50 and a counter 60, and the controller 20, the cigarette button 40, the power supply device 101, the conductive coil 32, the timer 50, the counter 60, the reminder device 70 and the driving mechanism 34 are electrically connected.

[0082] In this embodiment, the driving mechanism 34 includes a screw 343 and a motor 344 that drives the screw 343 to rotate, and the motor 344 is electrically connected to the controller 20 . The screw 343 is rotatably accommodated in the gap between the inner wall of the atomizing chamber 311 and the oute...

Embodiment 3

[0093] Embodiment 3 of the present invention provides a method for controlling an electronic cigarette. In this embodiment, the method for controlling an electronic cigarette is applied to an electronic cigarette 200 for illustration. Figure 4 As shown, the control method of the electronic cigarette may include:

[0094] Step 410, when the cigarette lighting signal is received, the cumulative heating duration of the part corresponding to the tobacco product in the heating zone where the heating element is currently located is acquired.

[0095] Among them, the cigarette lighting signal can be the pressing signal generated when the cigarette lighting button on the electronic cigarette is pressed, it can also be the airflow signal detected by the sensor (set in the airway connected to the mouthpiece) for detecting airflow, or it can be received by a microphone. The received voice control signals will not be described here one by one.

[0096] The implementation of this step ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com