Raw material measuring device and preparation blending device and preparation blending system

A technology of configuration device and raw material quantity, applied in the field of medical devices, can solve the problem that liquid raw materials are not easy to mix evenly, and achieve the effect of saving configuration time, ensuring configuration quality, and easy to stir evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

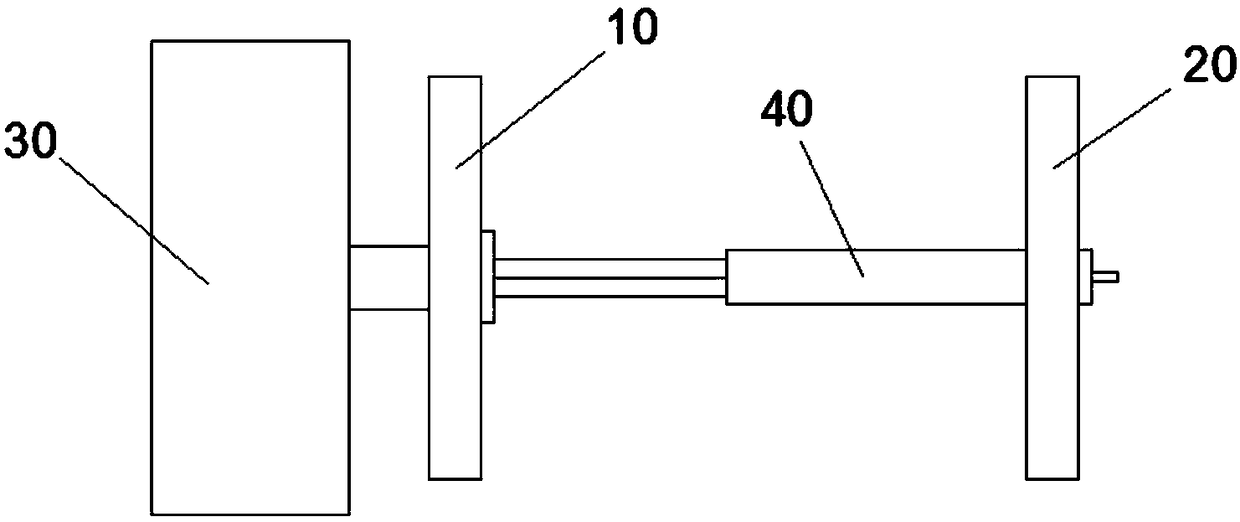

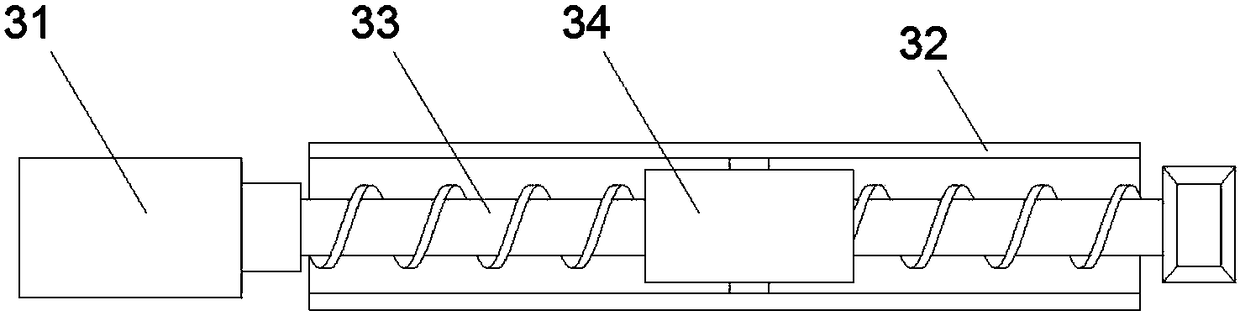

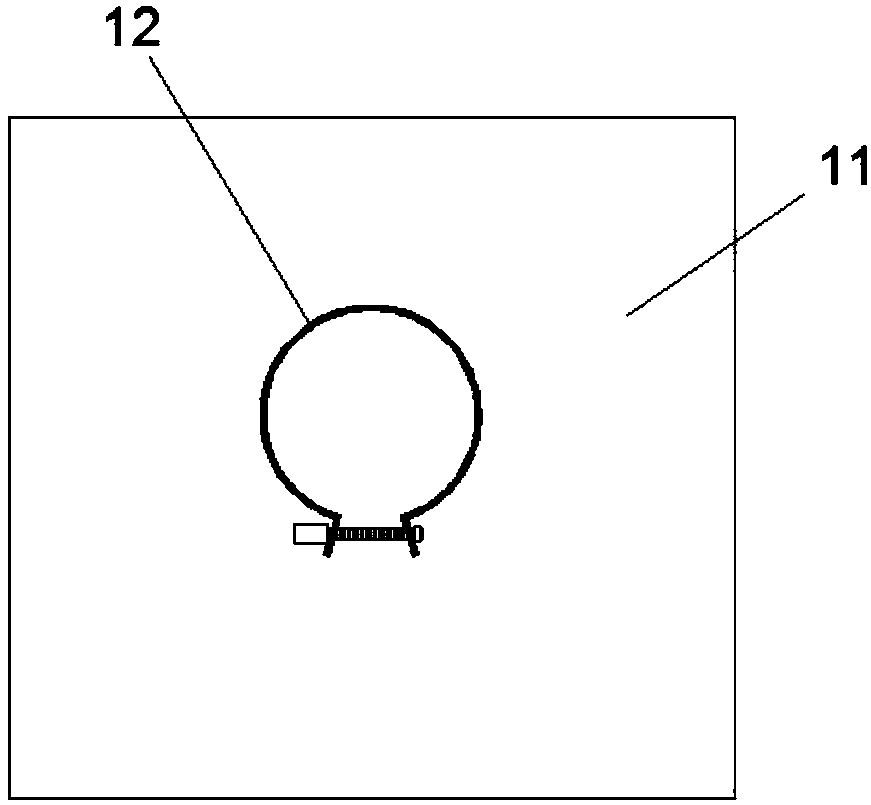

[0058] see figure 1As shown, the present embodiment provides a raw material measuring device, including a mobile module 10, a fixed module 20 and a drive module 30, between the mobile module 10 and the fixed module 20 for installing a syringe 40, the drive module 30 It is used to drive the moving module 10 to move towards the fixed module 20 to compress the syringe 40 so that the liquid material in the syringe 40 is squeezed out. When in use, the driving module 30 drives the mobile module 10 to compress the distance between the mobile module 10 and the fixed module 20 in an appropriate amount, and squeeze out the liquid material in the syringe 40 in an appropriate amount to realize the measurement of the liquid material.

[0059] Based on the above structure, this embodiment provides the following specific implementation modes. Under the premise of not conflicting with each other, several specific implementation modes can be combined arbitrarily to form a specific structure of...

Embodiment 2

[0065] see Image 6 with Figure 7 As shown, this embodiment provides a preparation configuration device, including at least two raw material measuring devices provided in Embodiment 1, as well as an information receiving module 70 , a controller and a base 60 . The at least two raw material measuring devices are installed on the base 60, the information receiving module 70 is used to receive the formulation information of the preparation and transmit it to the controller, the controller is used to The number of items controls the corresponding number of raw material measuring devices to measure liquid raw materials. When in use, the user can input formulation information to the formulation configuration device through the information receiving module 70, and then the controller controls the corresponding raw material measuring devices to start simultaneously to extrude one, two or more appropriate liquid raw materials at the same time.

[0066] In order to prevent the syrin...

Embodiment 3

[0079] see Figure 11 As shown, this embodiment provides a preparation configuration system, including a server and at least one preparation configuration device provided in Embodiment 2. The preparation configuration device is connected to a server through a communication module, the preparation configuration device is used to transmit the preparation formula information collected by the information receiving module 70 to the server, and the server is used to receive and store the preparation formula information. The preparation configuration system records each prepared preparation through the server, and the supervision of the configuration process is further strengthened, so that configuration records can be retrieved and traced to ensure configuration quality.

[0080] Wherein, the communication module can choose NRF24L01 chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com