Electronically-controlled automatic shaping mechanism for ceramic wall and floor tile patterns

A technology for wall and floor tiles and ceramics, which is applied in the direction of manufacturing tools and supply devices, etc. It can solve the problems that it is difficult to control the same pattern texture of ceramics, the pattern of ceramics is easy to deform, and the production efficiency is low, so as to solve the problem of simple cloth pattern and single technology Difficulties, diversification of fabric patterns, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

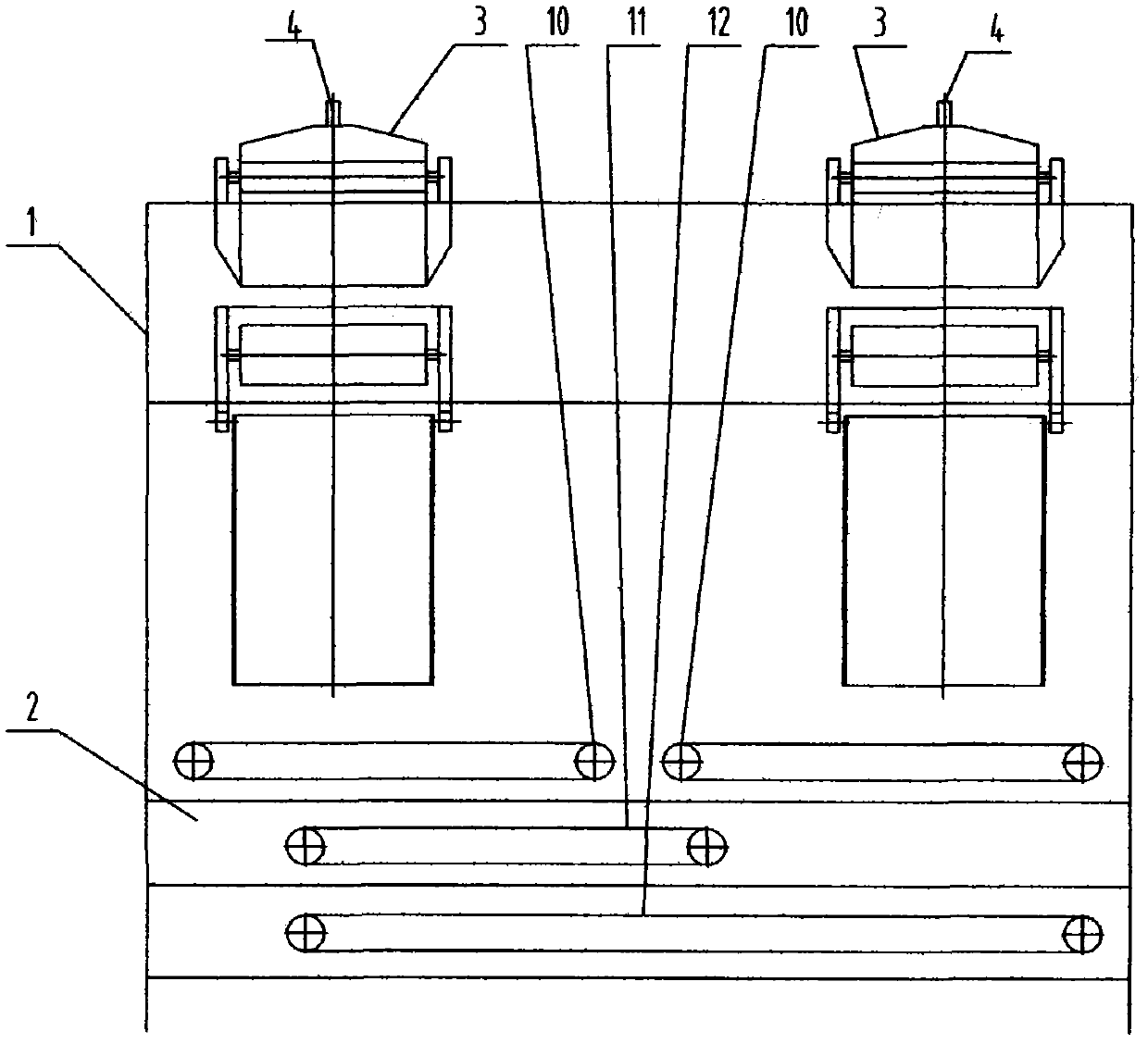

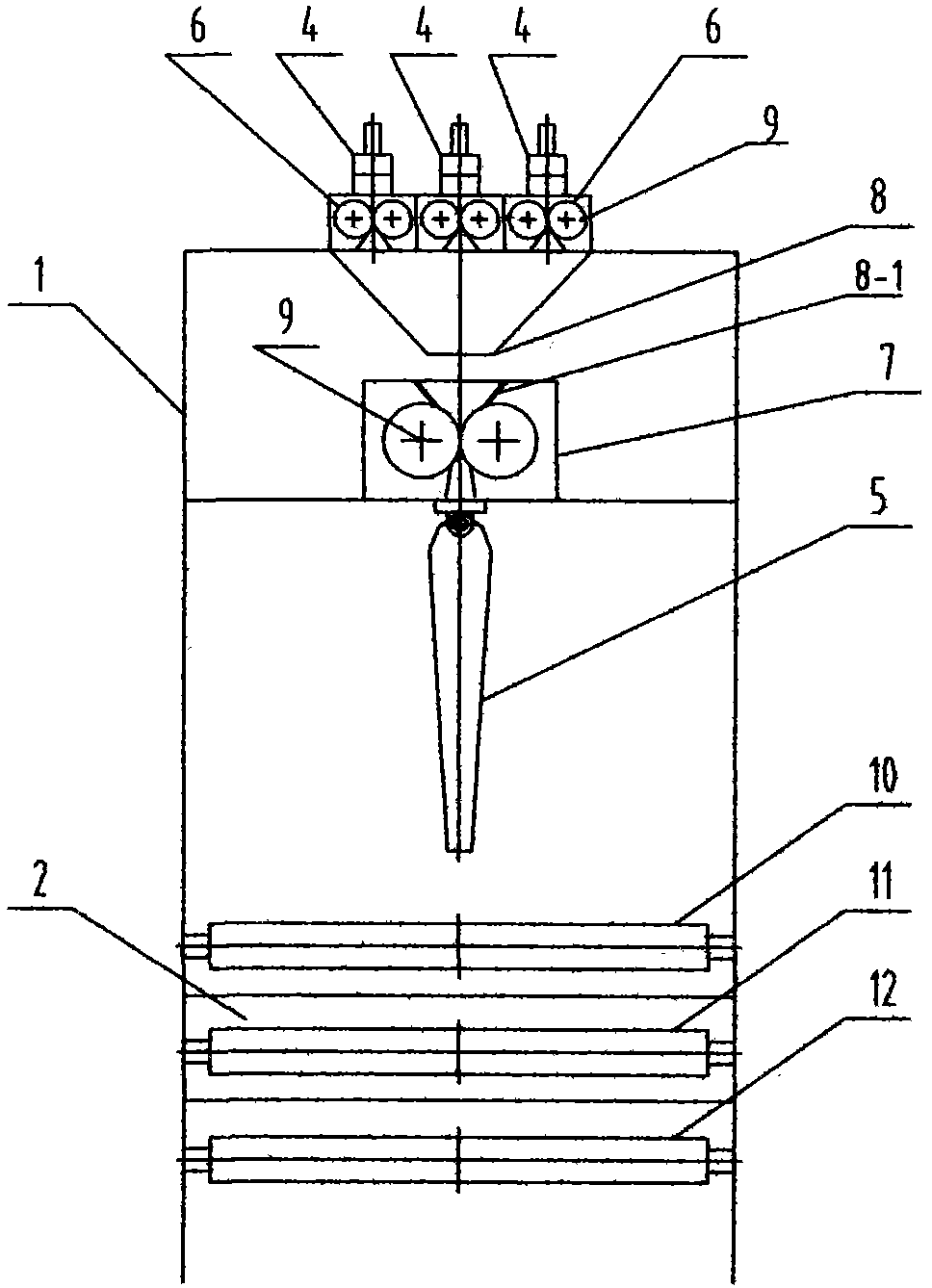

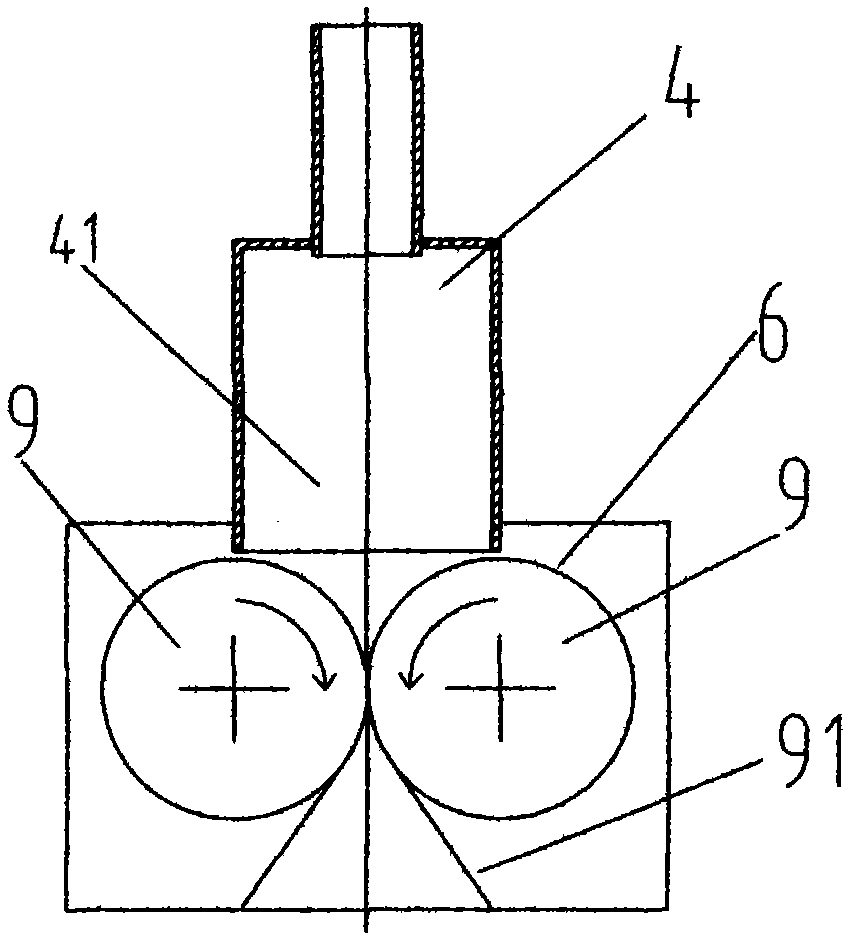

[0024] Such as Figure 1 to Figure 6 The automatic molding mechanism for the pattern of electrically controlled ceramic wall and floor tiles shown includes a frame 1 and a conveyor belt 2 . The frame 1 is provided with one or more groups of feeding assemblies 3, and the conveyor belt 2 is divided into a feeding belt 10, an aggregate belt 11 and a forming belt 12, and the feeding belt 10, the aggregate belt 11 and the forming belt 12 It is arranged under the spreading mechanism 5 in sequence from top to bottom, that is, the feeding belt 10 is set under the spreading mechanism 5, and the aggregate belt 11 is located under the feeding belt 10 and corresponds to the feeding position of the feeding belt 10. The forming belt 12 is located at the feeding position of the poly material belt 11 below the poly material belt 11. The control systems of the described feeding assembly 3 and the drive belt 2 are all connected to a computer-controlled operating system, and the feeding assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com