Glue application device

A plastic box and gluing technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as reducing the quality of gluing, and achieve the effect of improving gluing efficiency and good overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below by means of embodiments and in conjunction with the accompanying drawings.

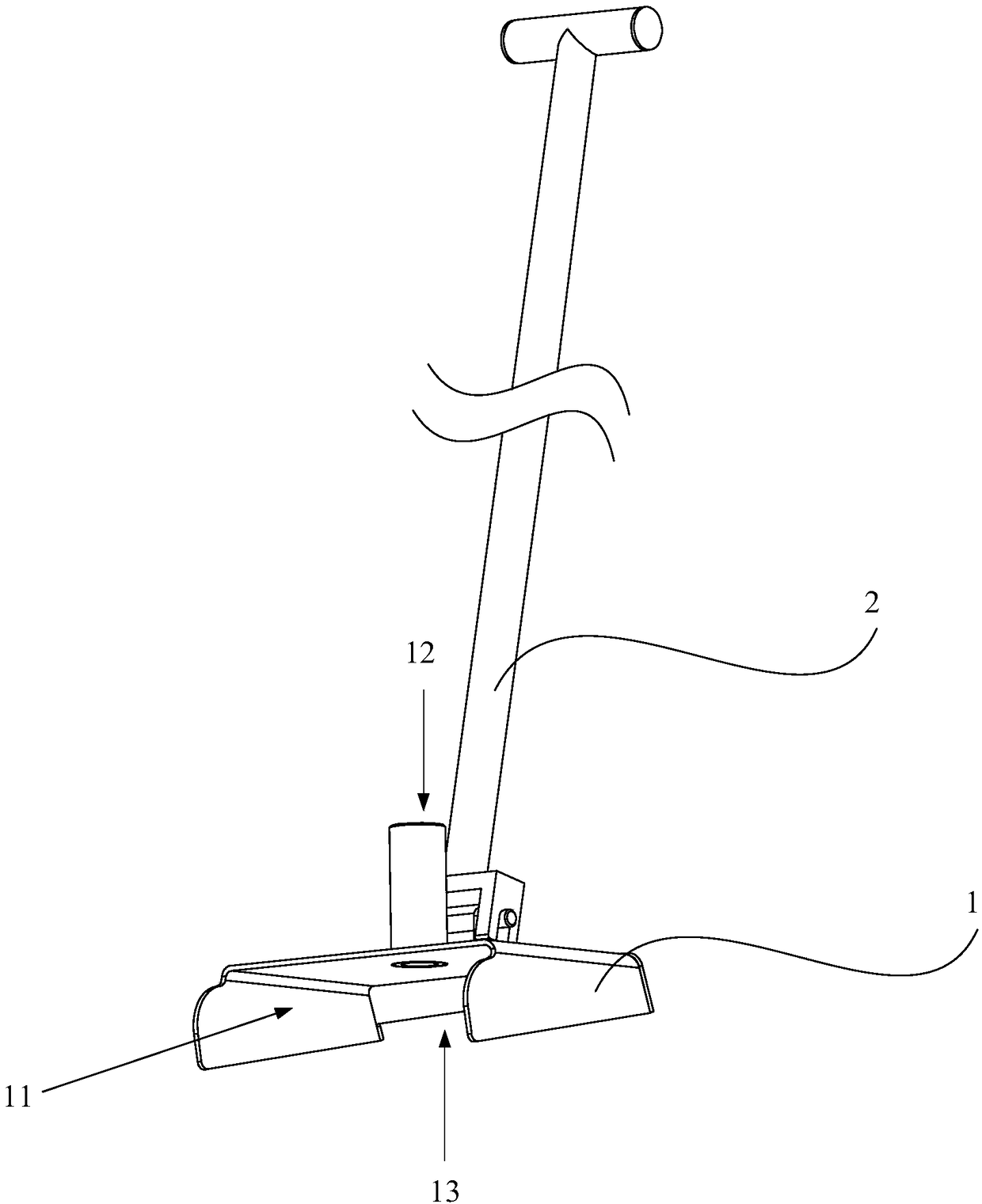

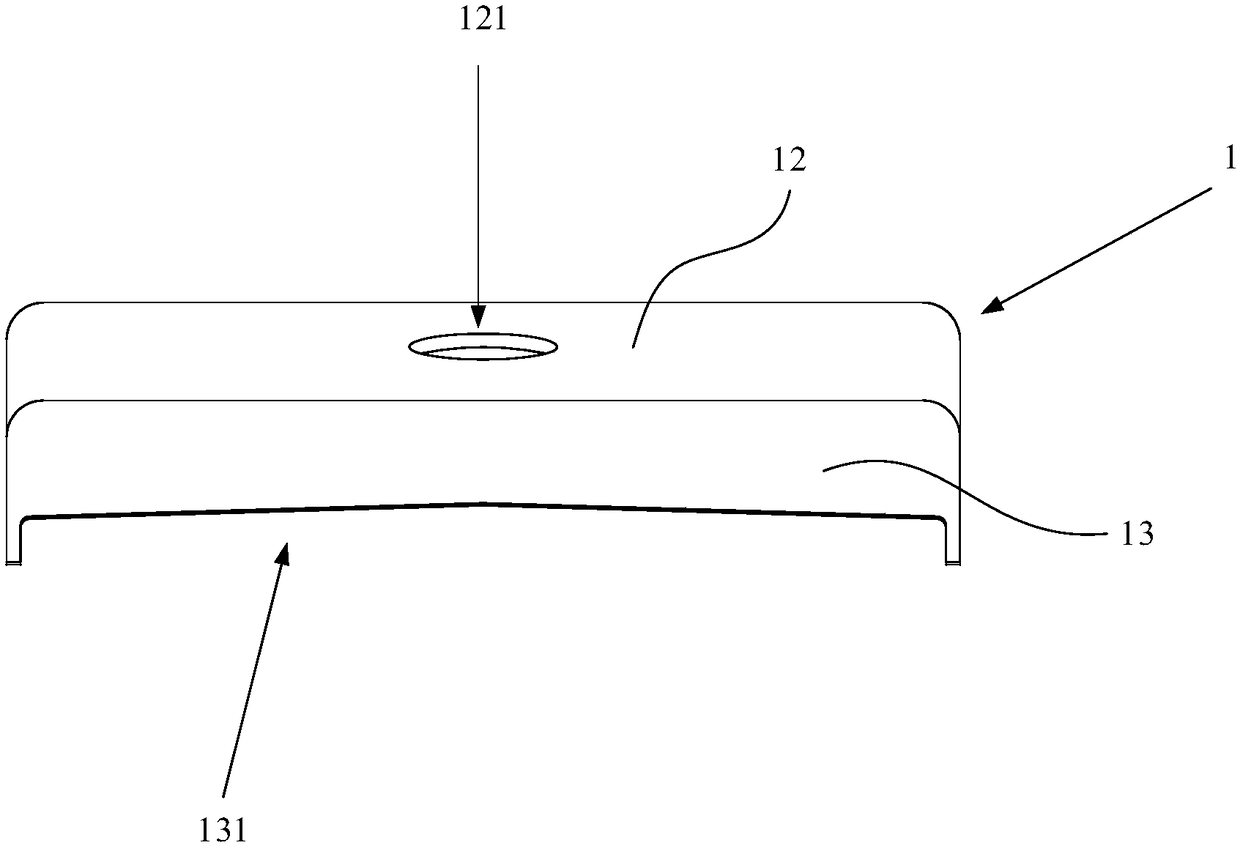

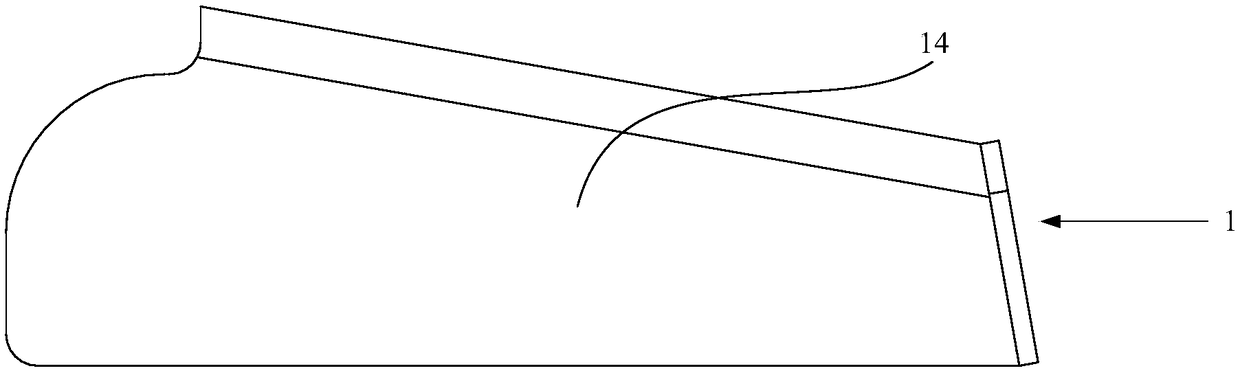

[0041] Such as Figure 1-2 As shown, the gluing device includes a gluing box 1 and a push rod 2 , and the pushing rod 2 is connected to the gluing box 1 . The gluing box 1 is integrally formed, so that the gluing device has a good overall structure, thereby avoiding long-term use and reducing the quality of gluing. There is no joint structure on the gluing box 1. Therefore, the defect of joint failure or instability caused by the curing of the epoxy structural adhesive in the joint structure in the prior art is avoided, thereby ensuring the stability of the glue after long-term use. quality. The glue box 1 is surrounded by a cavity 11 , the top surface 12 of the glue box 1 is provided with a glue inlet 121 , and the glue inlet 121 communicates with the cavity 11 . The bottom surface of the gluing box 1 is opened to form a bottom opening. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com