Laser cutting machine

A technology of laser cutting machine and laser cutting head, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., and can solve the problems of automatic cutting and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

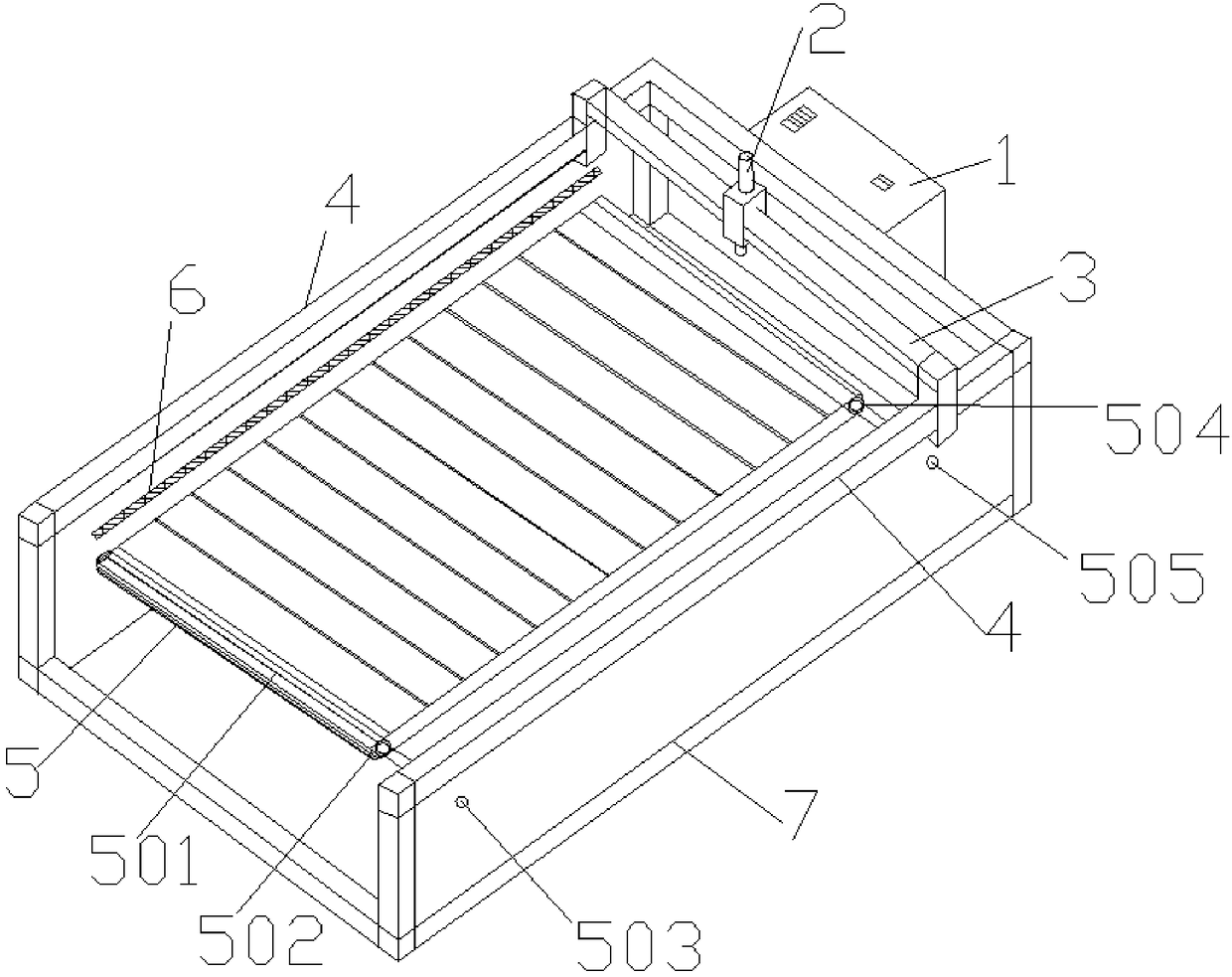

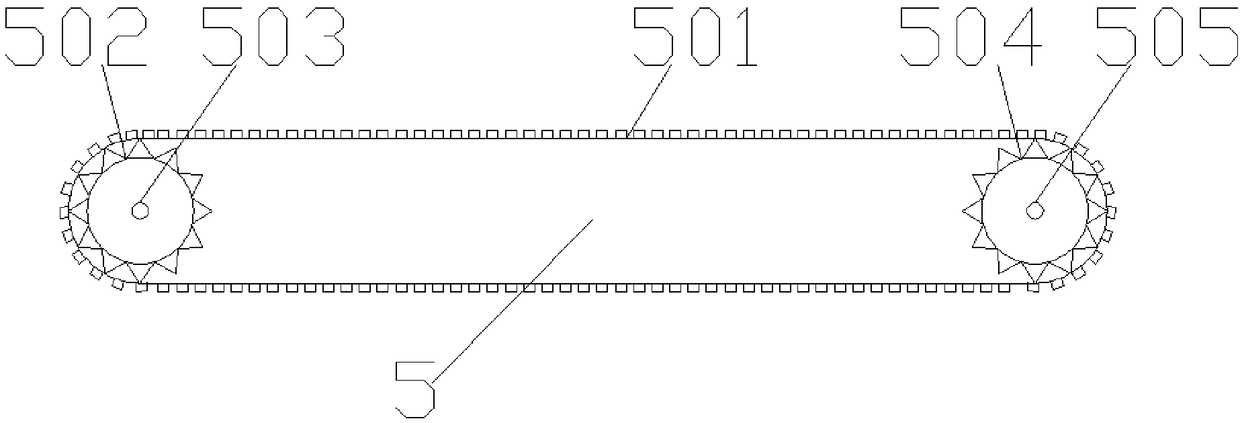

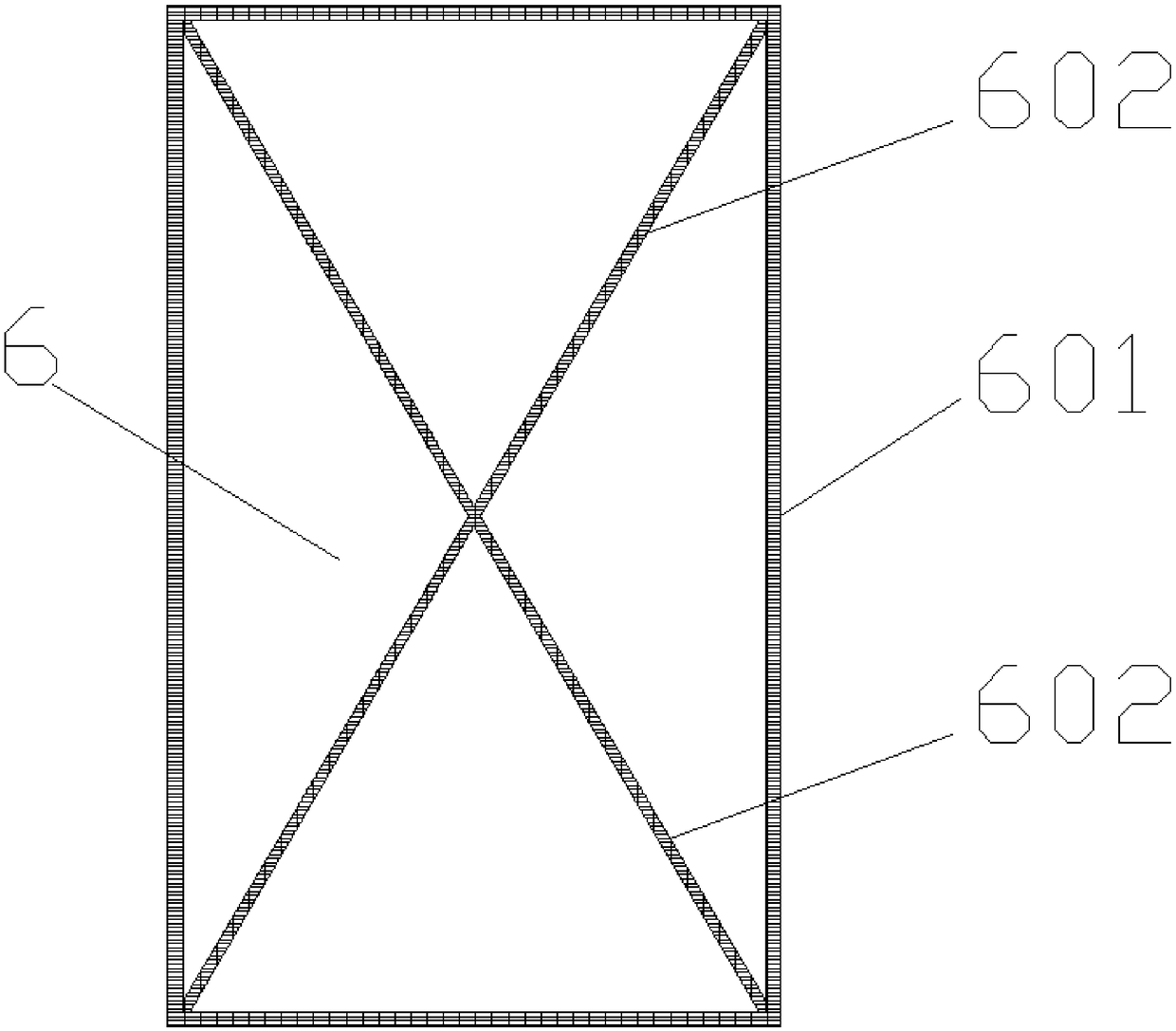

[0016] Such as Figure 1 to Figure 3 As shown, a laser cutting machine includes a base 7, a controller 1, a laser cutting head 2, a cross arm 3, a slide rail 4, and a workbench 6. A workbench 6 is installed on the base 7, and the slide rail 4 is installed on On the base 7, the cross arm 3 is erected on the slide rail 4 and can move back and forth on the slide rail 4. The laser cutting head 2 is installed on the cross arm 3 and can move up and down; the laser cutting machine also includes an automatic unloading mechanism 5 , the automatic blanking mechanism 5 is installed on the base 7 and below the workbench 6. The automatic blanking mechanism includes a crawler belt 501, a main transmission gear 502, a main transmission shaft 503, an auxiliary transmission gear 504, an auxiliary transmission shaft 505, and the main transmission Shaft 503 and auxiliary transmission shaft 505 are all installed on the base 7, main transmission gear 502 and auxiliary transmission gear 504 are eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com