Machining device for water-discharging electric-type crank-type metal pipe fitting pipe joint

A technology for processing devices and metal pipe fittings, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of unstable hand-held mode, low work efficiency, and poor connection, etc., and achieves good processing effect and smooth processing The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

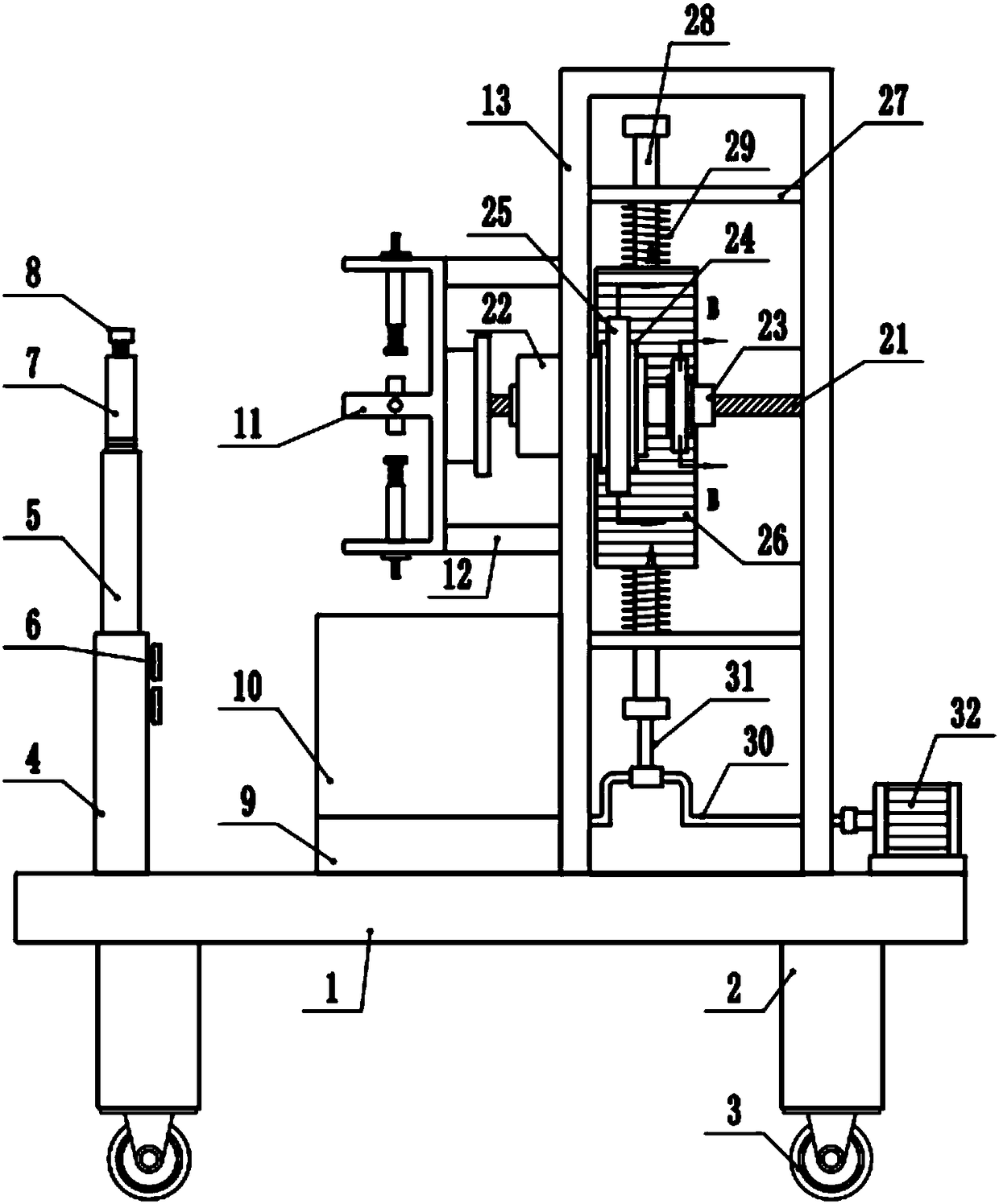

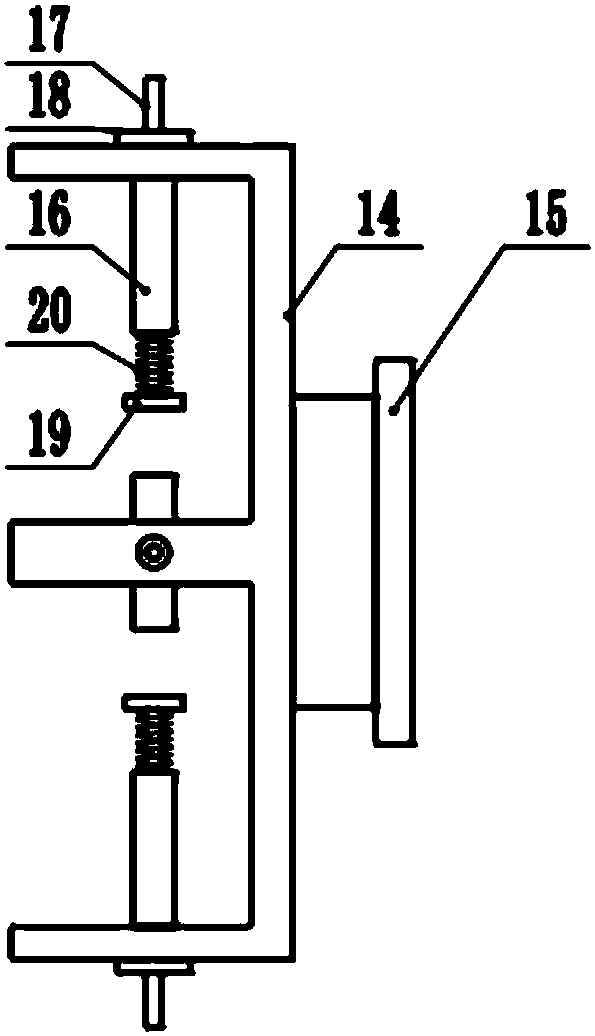

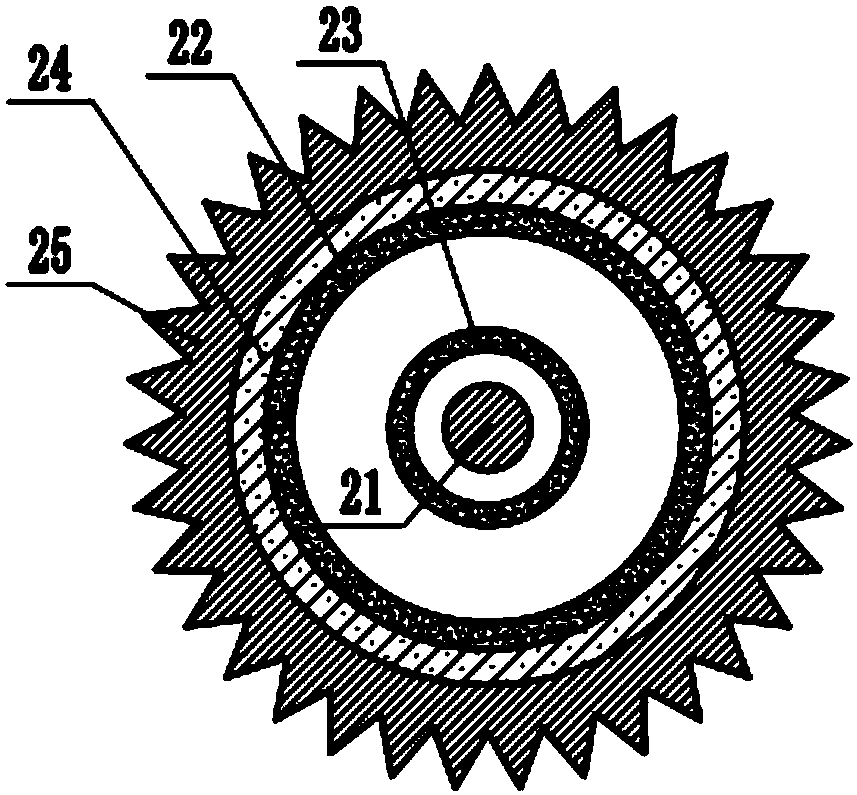

[0021] see Figure 1-4, an electric crank-type metal pipe joint processing device for launching, comprising a device body, the device body is provided with a base 1, the bottom of the base 1 is provided with a support column 2, and the support column 2 and the base 1 Fixedly connected by welding, the bottom of the supporting column 2 is provided with a walking wheel 3, the traveling wheel 3 and the supporting column 2 are fixedly connected by the action of a bracket, and a supporting structure is arranged on the base 1, and the supporting structure Set on the left side of the base 1, the supporting structure includes an outer adjustment cylinder 4, an inner adjustment cylinder 5, a fastening knob 6 and a positioning frame 7, and the bottom of the outer adjustment cylinder 4 is fixedly connected to the base 1 by welding, The inner adjustment cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com