Polishing device of disk type parts

A technology for polishing and grinding disc parts, which is applied in the field of parts processing, can solve the problems of low processing efficiency, slow processing speed, and affecting the quality of parts, so as to improve the grinding accuracy and processing efficiency and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

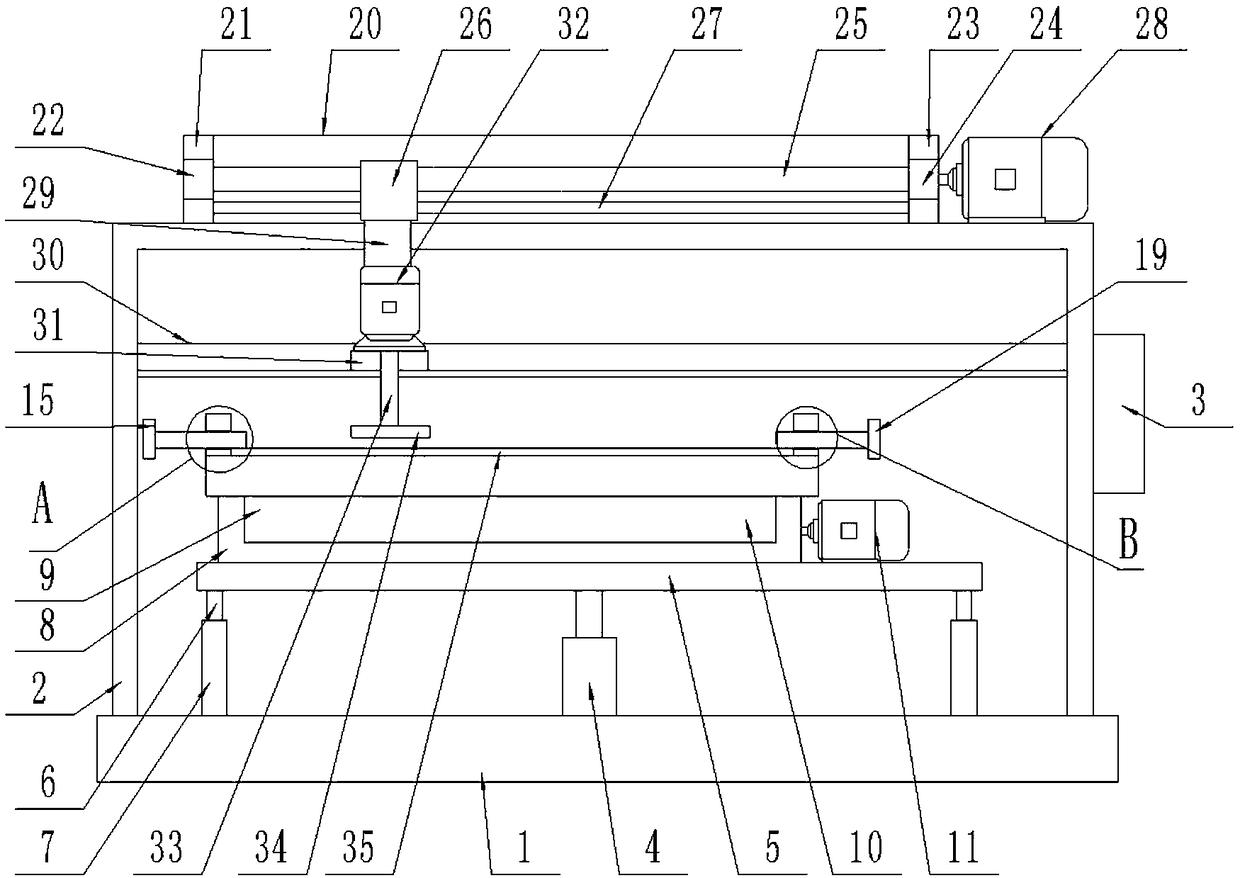

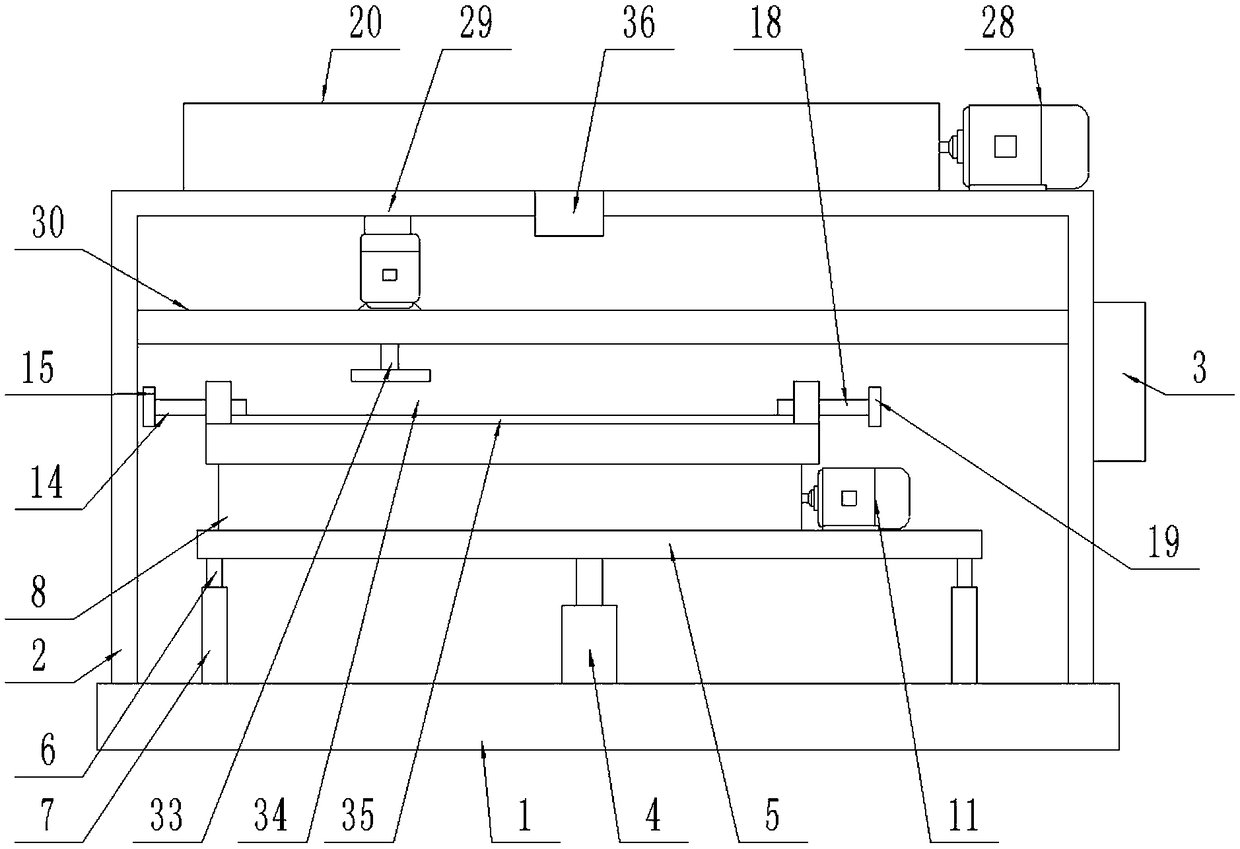

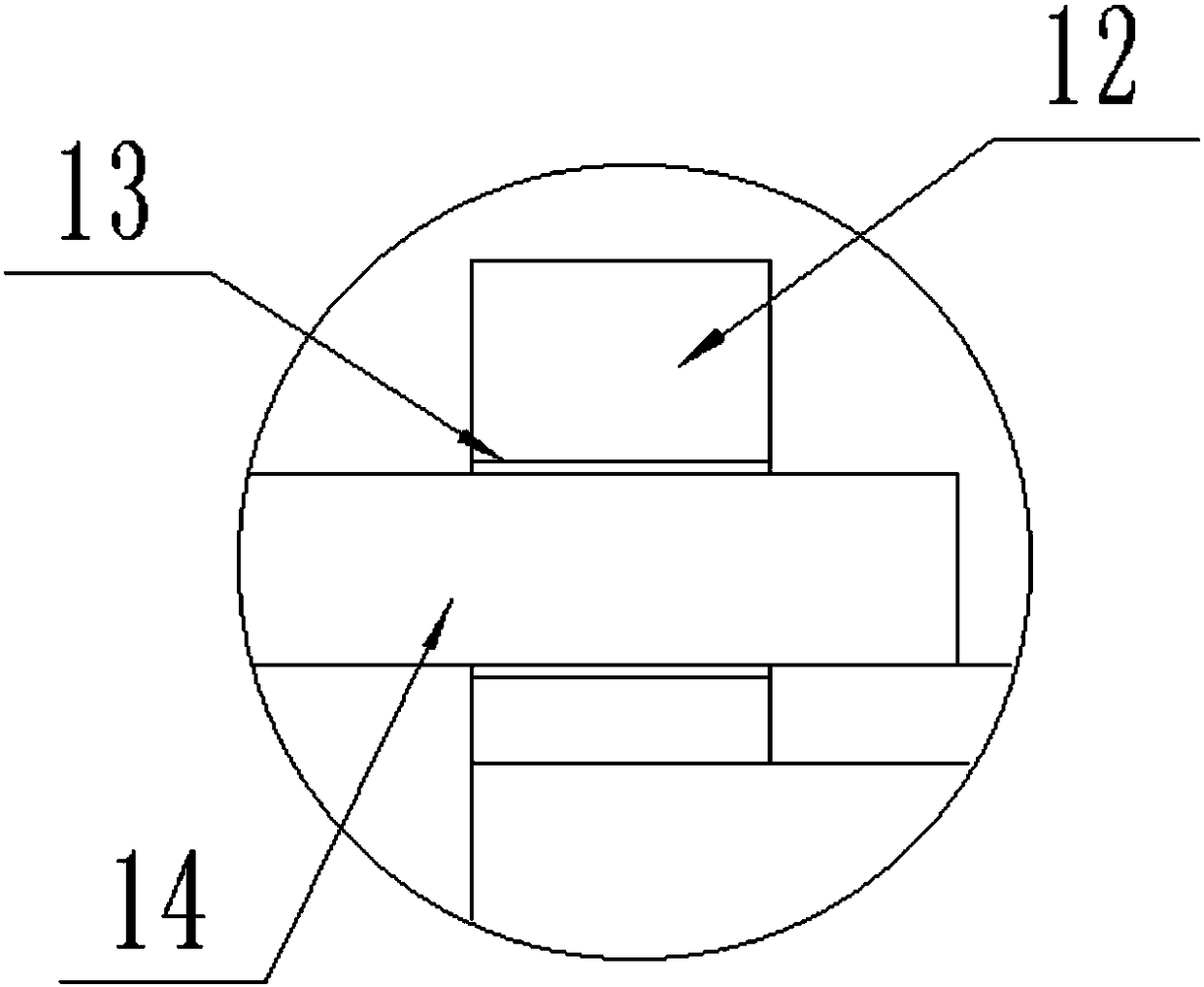

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a polishing and grinding device for disk parts includes a base 1, a gantry frame 2, a rotary mechanism, a locking mechanism, a grinding mechanism, a traverse mechanism, a lifting mechanism and a controller 3, and the lifting mechanism is fixed on the The servo cylinder 4 on the base 1, the lifting plate 5 fixed on the telescopic end of the servo cylinder 4, the positioning rods 6 fixed at the four corners of the lower end of the lifting plate 5, fixed on the base 1 and positioned at the positioning The positioning sleeve 7 directly below the rod 6 is jointly constituted, and the slewing mechanism is composed of a slewing base 8 fixed on the lifting plate 5, a slewing support 9 embedded on the slewing base 8, and the slewing support 9 The connected revolving platform 10 and the reduction motor 11 connected with the slewing support 9 are jointly constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com