Cylindrical casting surface polishing device

A technology for cylindrical castings, which is applied in the direction of grinding drive devices, grinding machines, grinding racks, etc., can solve the problems of reducing work efficiency, grinding castings, and uneven grinding of casting surfaces, so as to improve work efficiency and realize The effect of mechanization and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

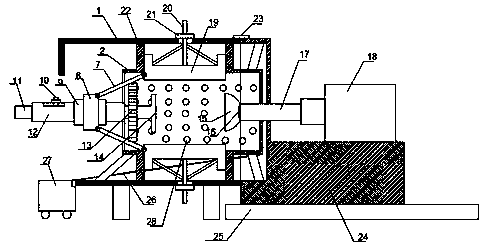

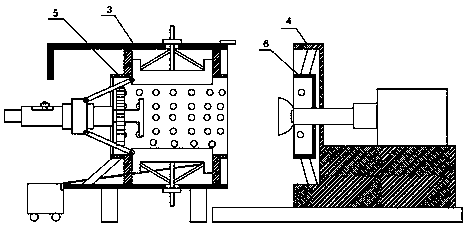

[0015] The present invention will be further described in detail below in conjunction with the drawings:

[0016] Such as figure 1 As shown, a cylindrical casting surface grinding device of the present invention includes a transverse cylindrical outer cylinder 1. A transverse cylindrical inner cylinder 2 is provided in the outer cylinder 1. The outer cylinder 1 is divided into left and right outer The tube 3 and the outer right tube 4, the inner tube 2 is divided into an inner left tube 5 and an inner right tube 6, which can be docked left and right, the outer left tube 3 is connected with the inner left tube 5, and the outer right tube 4 is connected with the inner right tube 6. A base 24 is connected to the right side of the outer right cylinder 4, a drive motor 18 is arranged above the base 24, and left and right extending rails are laid under the base 24. The drive motor 18 is drivingly connected to a rotating shaft 17, and the end of the rotating shaft 17 passes through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com