Adjustable-type precise sorting fixture

An adjustable and jig technology, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of manual grasping difficult to keep up with the rhythm, unable to keep up with the rhythm of labor intensity, labor intensity of workers, etc., to achieve versatility and Strong practicability, reliable performance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

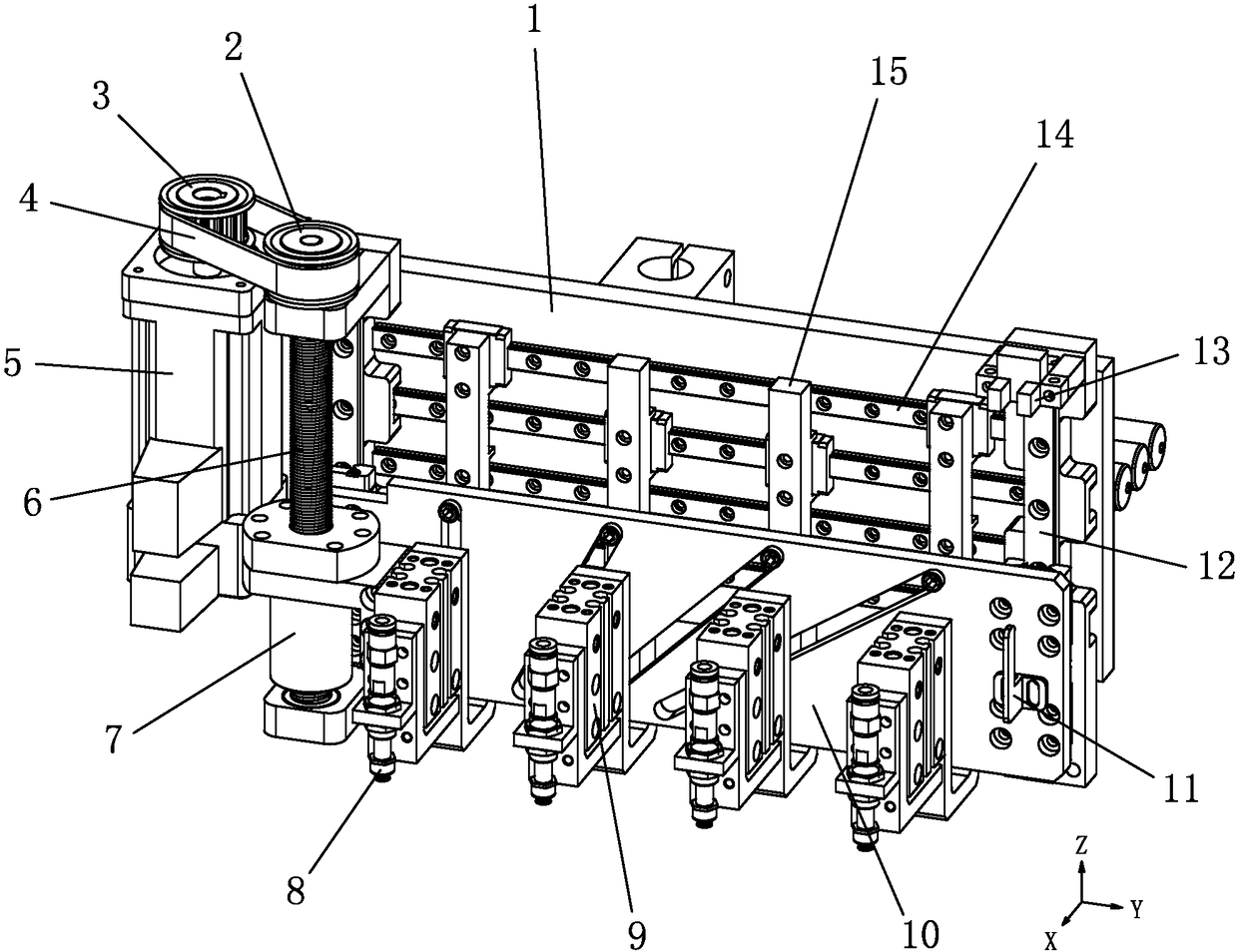

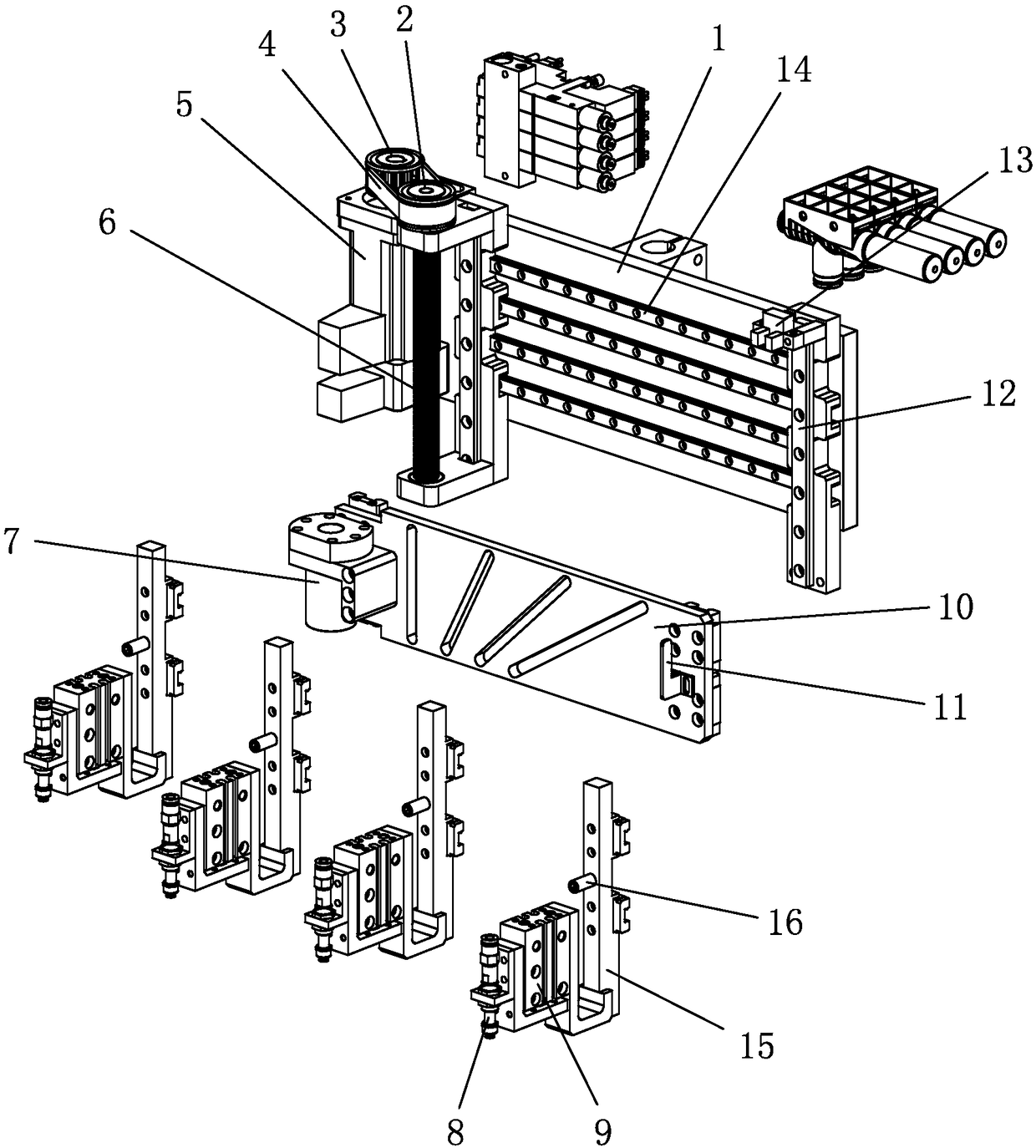

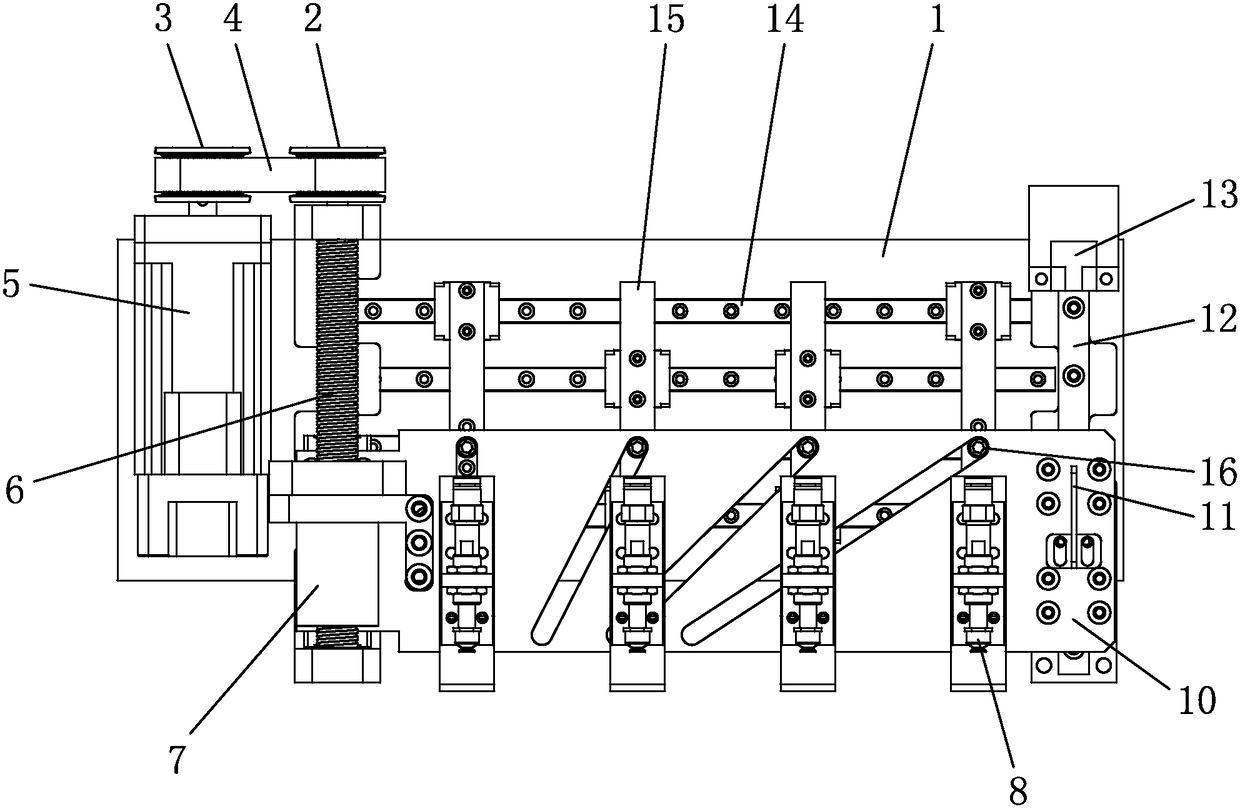

[0021] see Figure 1-Figure 6 , this adjustable precision sorting fixture includes a fixture carrier plate 1 used to connect to the robot, and a drive mechanism, an adjustment mechanism, and more than two grasping units respectively arranged on the fixture carrier plate 1. This embodiment is provided with four Grabbing unit; the driving mechanism is arranged on one side of the fixture carrier plate 1; the adjustment mechanism includes a guide plate 10 sliding on the front of the fixture carrier plate 1, and the driving mechanism drives the guide plate 10 to reciprocate and slide along the Z axis; the grabbing unit includes sliding on the fixture carrier plate 1 The transplanting bracket 15 on the front of the plate 1, the guide plate 10 is provided with a guide groove matching with the grasping unit, and the transplanting bracket 15 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com