Insert-type needle bed for computerized flat knitting machines

A computerized flat knitting machine and panel-type technology, which is applied in the directions of knitting, weft knitting, textiles and papermaking, etc., can solve the problems of difficulty in transferring loops and joining loops, slow knitting speed, insufficient rational damping of knitting needles, etc. To achieve the effect of reducing the excessive swing of the needle tip, avoiding the different sizes of the needle grooves, and reducing the entry of dust into the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

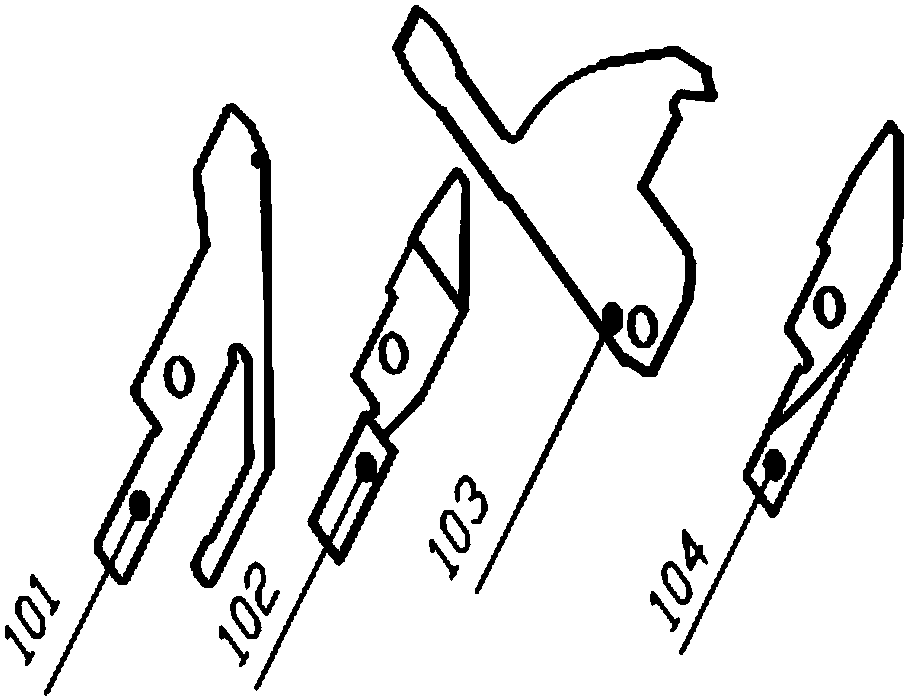

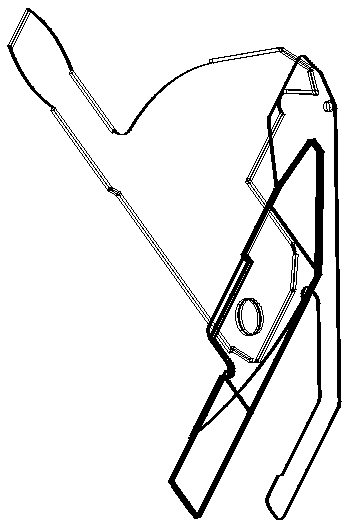

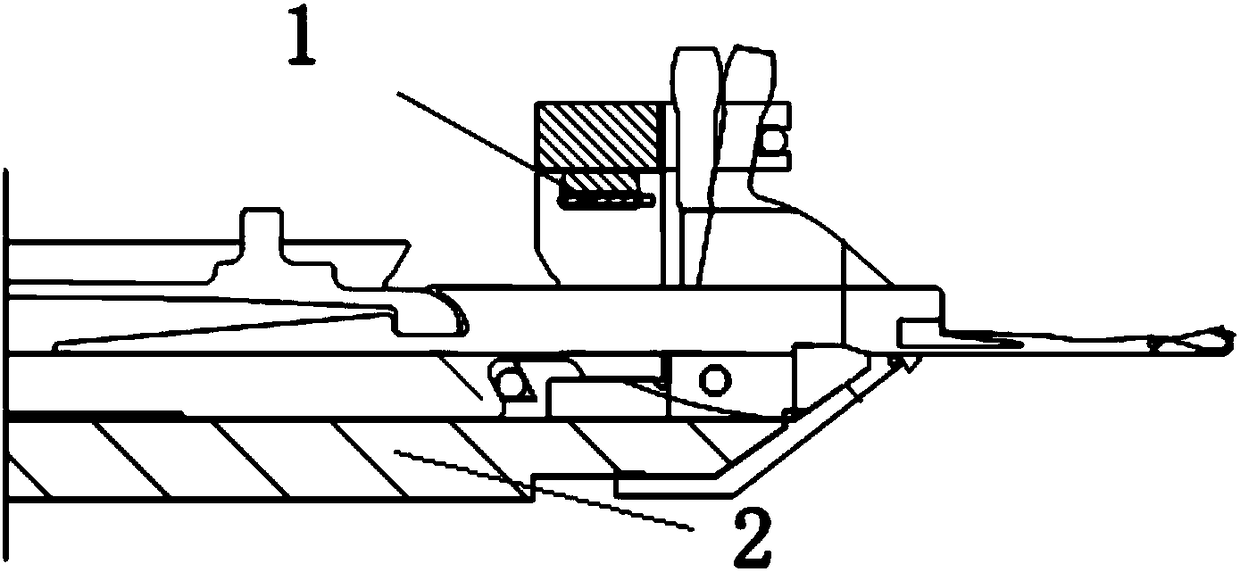

[0026] The invention will be further described below in conjunction with specific embodiments and accompanying drawings:

[0027] Refer to attached Figure 1-10 As shown, the invention: a panel type needle bed applied to a computerized flat knitting machine, including a panel type needle bed base plate 2 with a front needle track installation groove and a combined panel with a front needle track at the doffing port. The two side walls of the front needle track installation groove of the panel type needle bed base plate with the front needle track installation groove are provided with grooves 8 for reducing the thickness of the side walls. The bottom surface of the groove is arc-shaped, and the doffing The two sides of the needle track combined insert in front of the mouth are provided with arc bosses corresponding to the grooves, and the bottom surface of the arc bosses is in a matching arc shape.

[0028] A panel type needle bed applied to computerized flat knitting machines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com