Convex piece adapted to main body of door frame, molded door and method for preparing molded door

A door frame and main body technology, which is applied in the field of the preparation of molded doors, can solve the problems of limited strength of molded doors, lack of stereoscopic visual effects, complicated processing procedures, etc., and achieves the effects of reducing damage, convenient and quick assembly, and speeding up production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

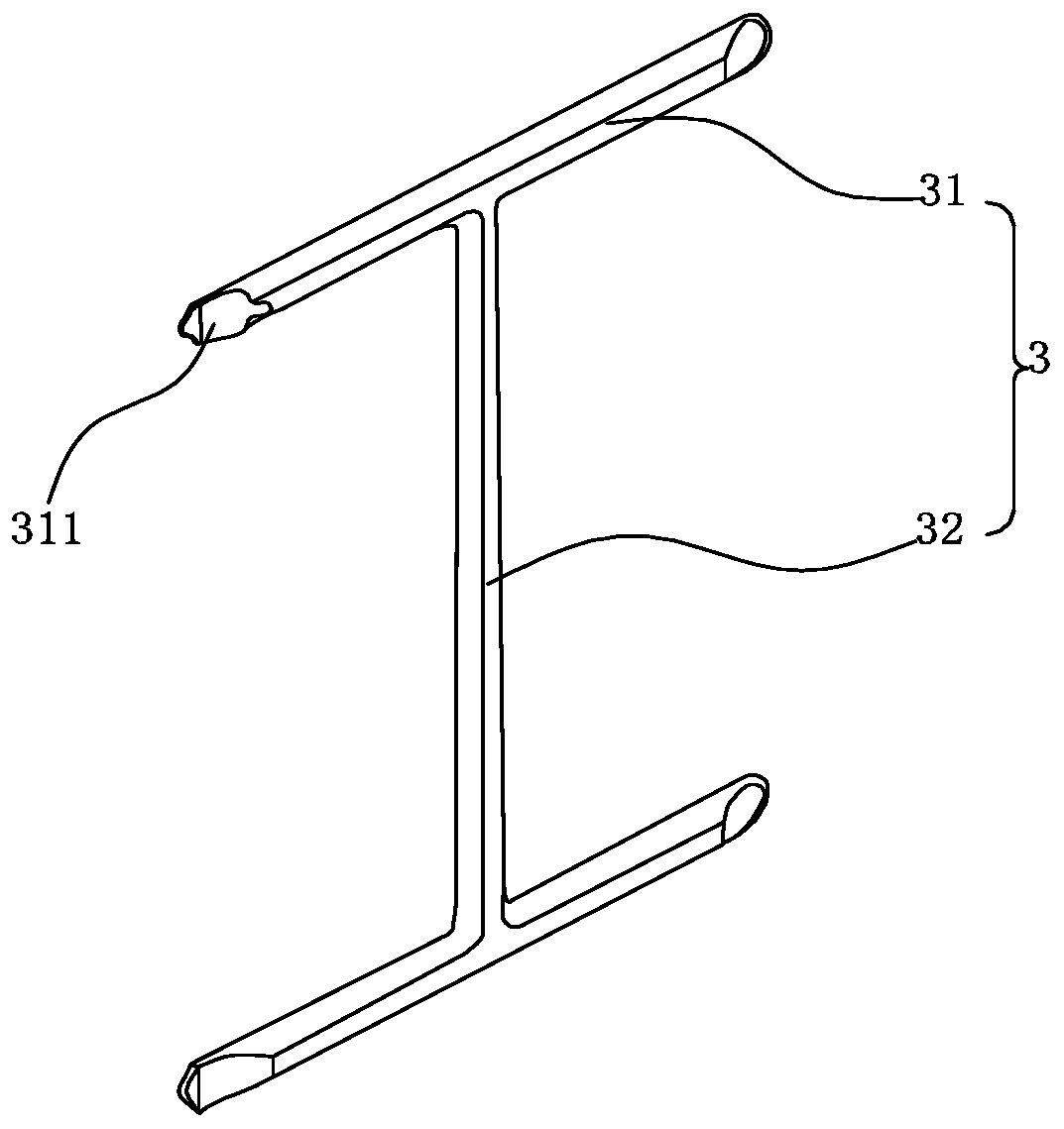

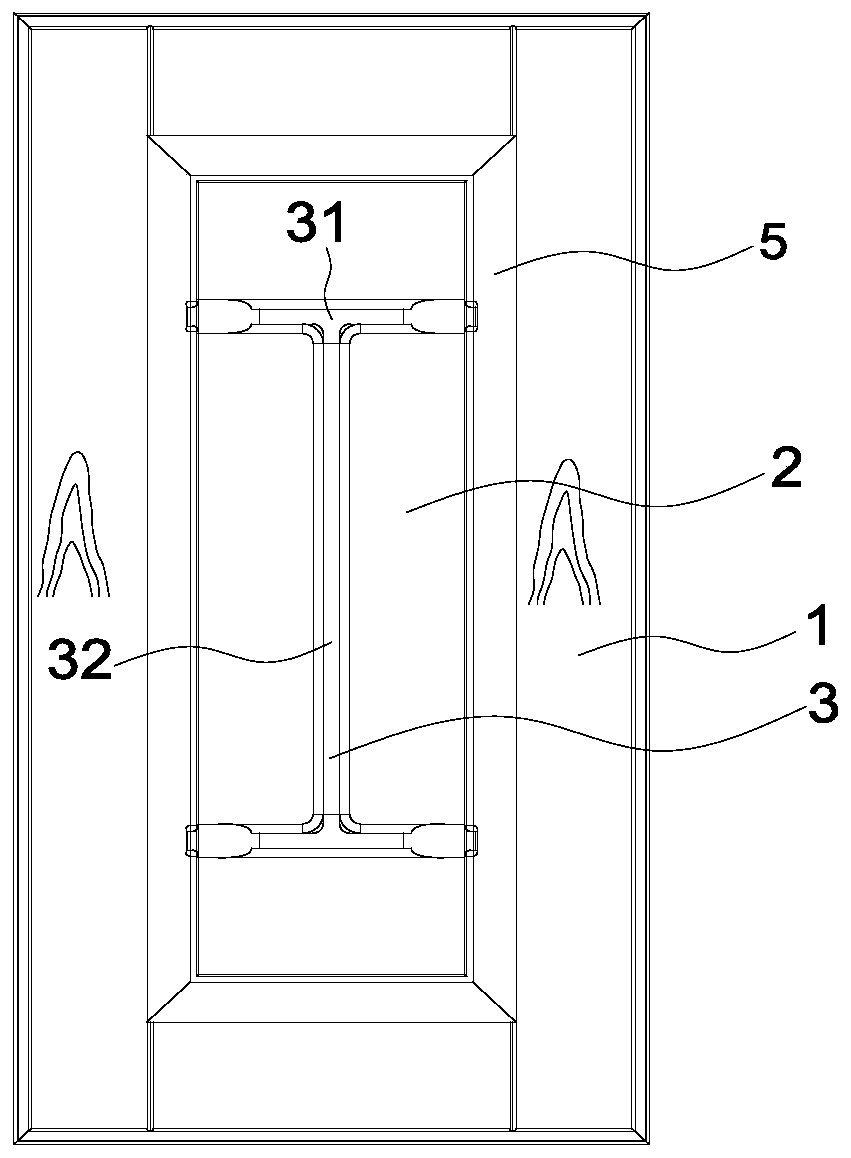

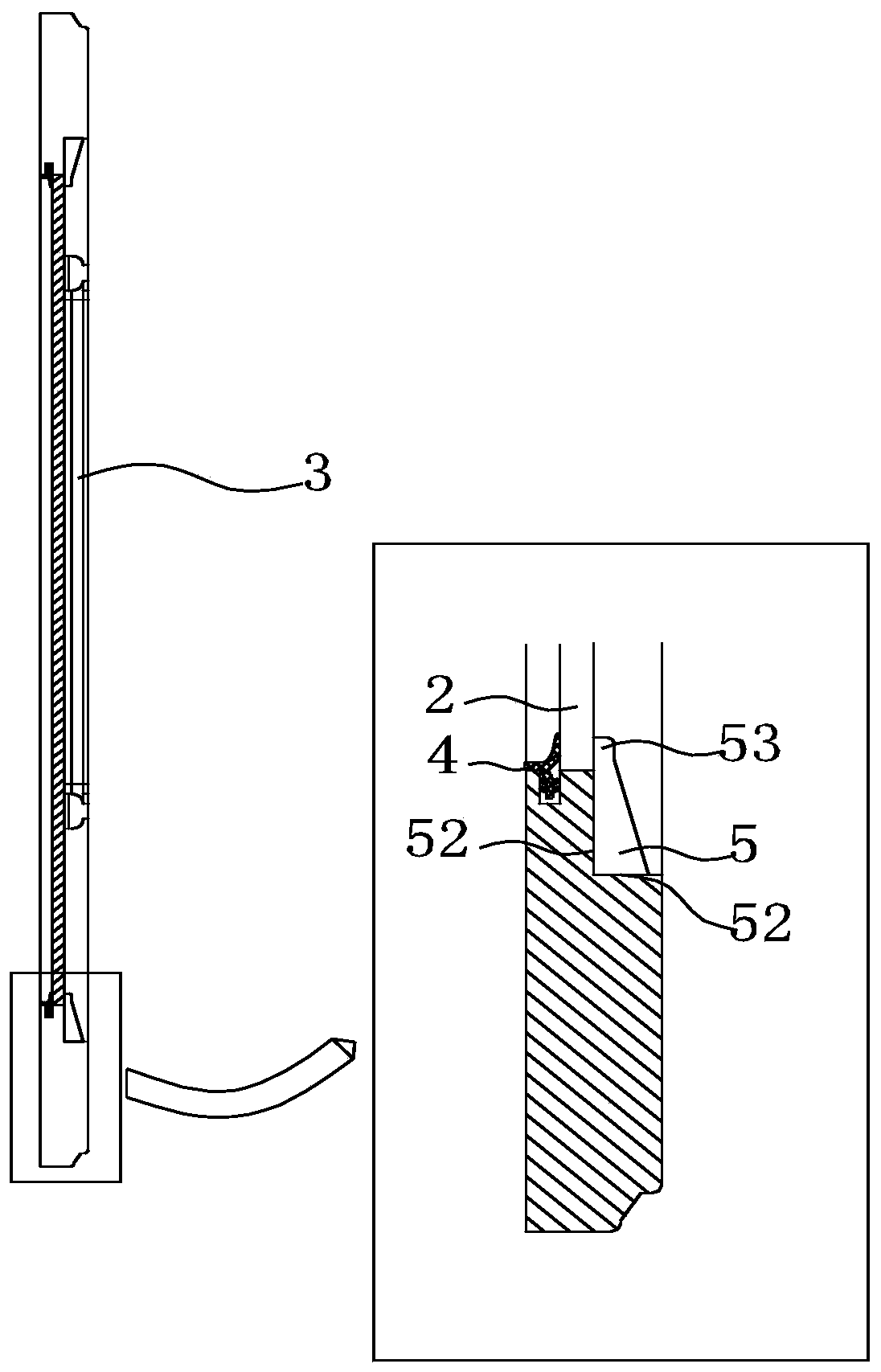

[0042] Such as figure 1As shown, it is a convex part of an embodiment of the present invention, the convex part is an I-shaped part 3, and the I-shaped part 3 includes two horizontal supports 31 and a vertical support 32, and the vertical support 32 The two ends are respectively connected with the middle parts of two transverse supports 31 , and the two transverse supports 31 and one vertical support 32 are integrally formed and are on the same plane. Tenons 311 are provided at both ends of the two transverse supports 31 , and the tenons 311 are heads extending from both ends of the transverse supports 31 . Thus, the two transverse brackets 31 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com