Novel anti-torsion small drill collar joint

A drill collar, a new type of technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of fishing tools and drilling tools falling into the well, small undercut torque, and serious scale sticking in the center pipe, so as to improve the operation success rate and Safety, avoiding undercut problems, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

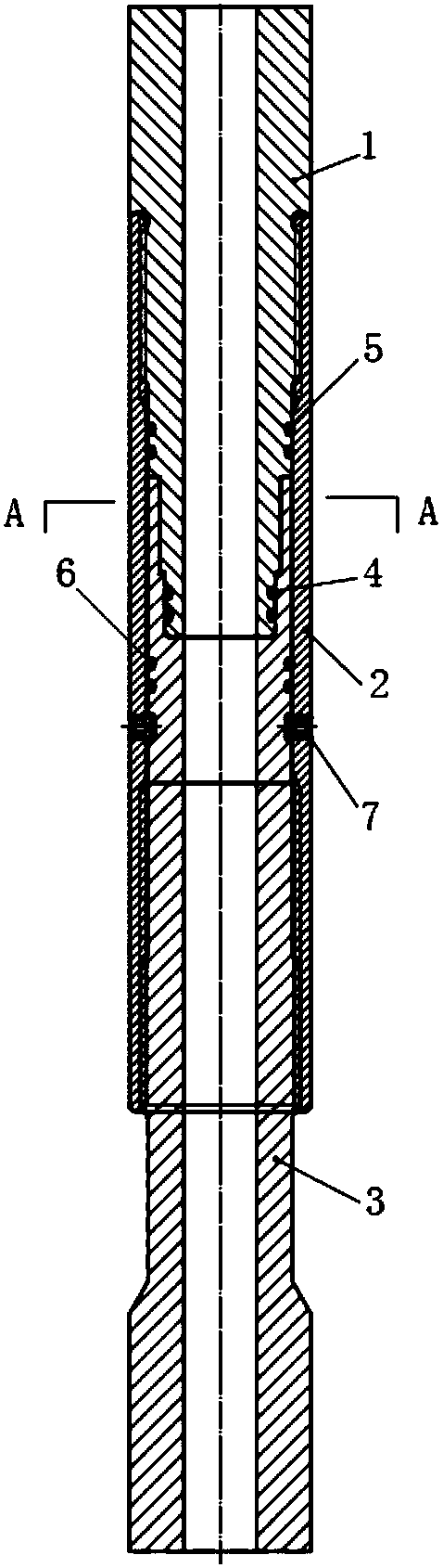

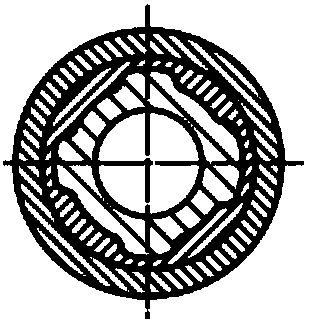

[0020] Such as figure 1 and figure 2 As shown, the new torsion-resistant small drill collar joint of the present invention includes a connecting sleeve 2, an upper joint 1 is arranged inside the upper end of the connecting sleeve 2, and a lower joint 3 is arranged inside the lower end of the connecting sleeve 2. The upper joint 1 and the lower joint 3 are connected by splines and spline grooves, which can ensure that the upper joint 1 and the lower joint 3 do not rotate relative to each other, and can withstand relatively large torques, ensuring that the connecting threads no longer bear external torques. The contact surfaces of the upper joint 1 and the lower joint 3 are provided with a first sealing ring 4 to ensure sealing. The connecting sleeve 2 and the upper joint 1 are threadedly connected, and can bear the tension pressure. The contact surface of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com