Anti-loose screw

A technology of anti-loosening and screw application in the direction of screws, nuts, bolts, etc., which can solve the problems of complex and difficult forming molds, high cost, and difficult manufacturing, and achieve the effect of low mold cost, simple and cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

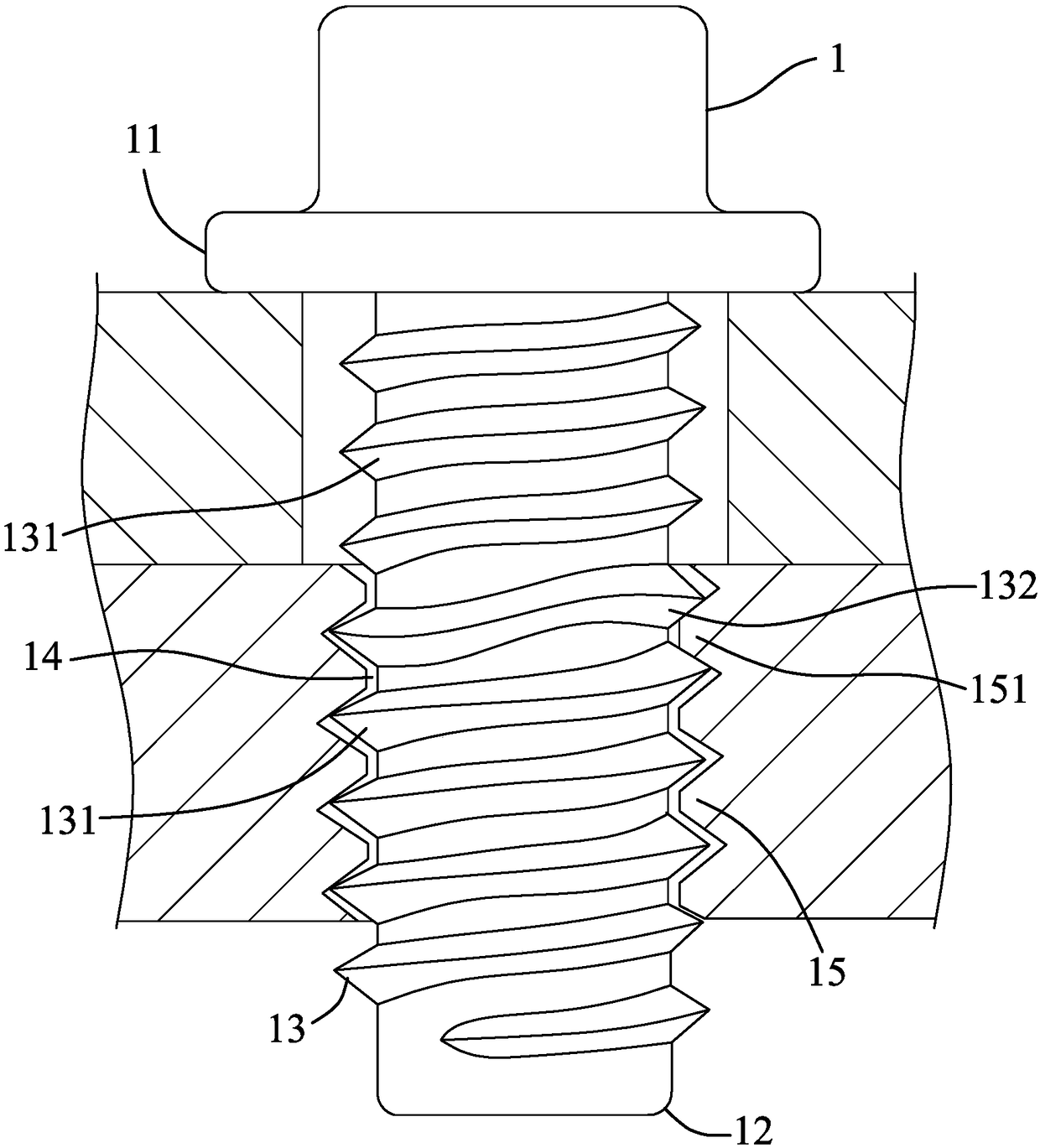

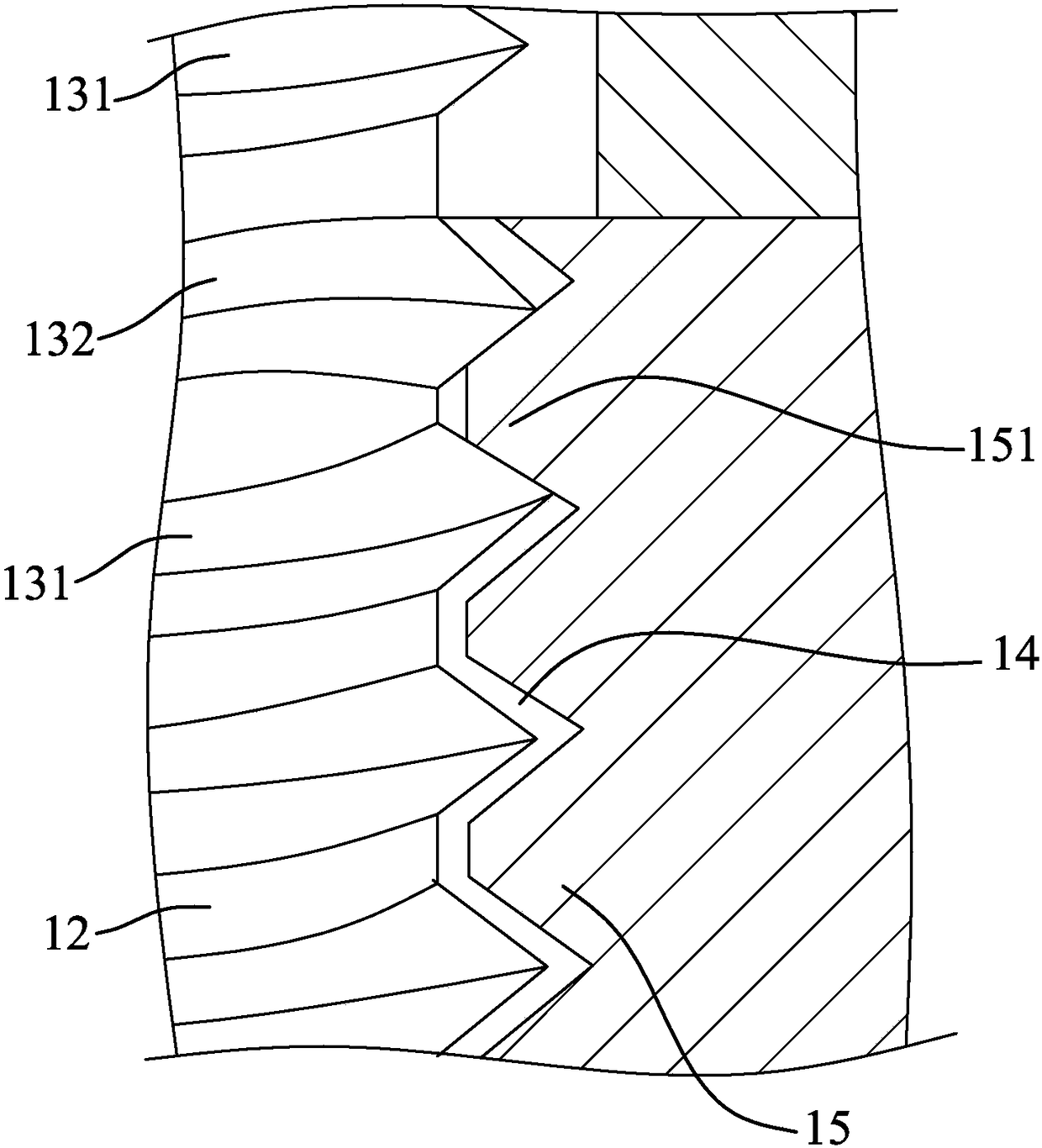

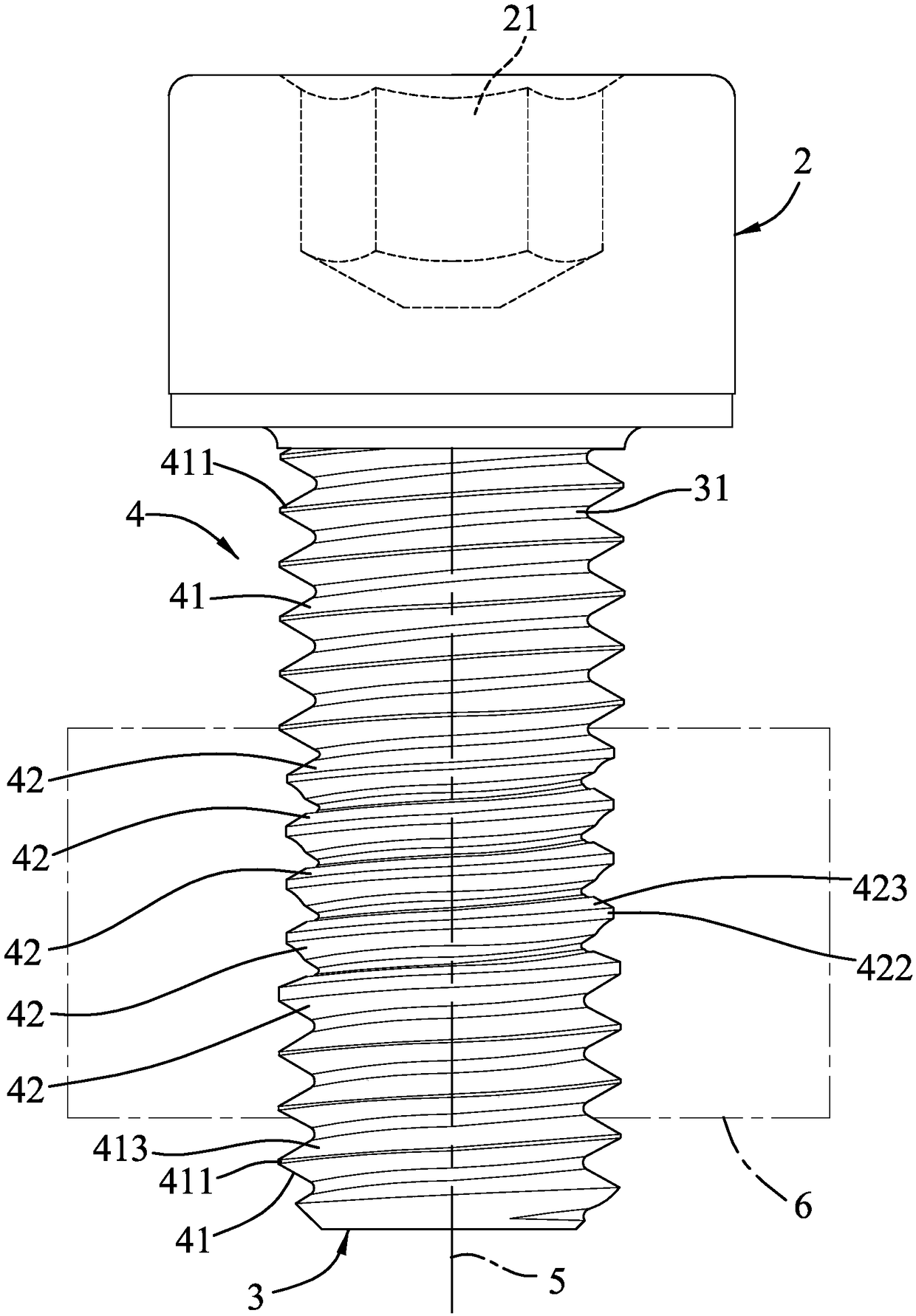

[0021] refer to image 3 and Figure 4 , an embodiment of the anti-loosening screw of the present invention includes a screw head 2, a screw body 3, and an anti-loosening thread 4, and defines a central axis 5 passing through the center of the screw head 2 and the screw body 3.

[0022] The screw head 2 includes a screw head groove 21 formed on one end surface, and the screw head groove 21 can be used for locking a tool such as a flat-shaped screwdriver or a cross-shaped screwdriver. In other variations of this embodiment, the screw head 2 can also be locked using other auxiliary tools such as a wrench or a finger, and it is not necessary to provide the screw head groove 21 .

[0023] The screw body 3 is a cylinder extending longitudinally along the central axis 5 from an end surface of the screw head 2 opposite to the screw head groove 21 , and includes an outer peripheral surface 31 around the central axis 5 .

[0024] The anti-loosening thread 4 is helically disposed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com