Lubrication system oil way structure of vertical type high speed case

A technology of lubrication system and high-speed box, which is applied in the direction of gear lubrication/cooling, transmission box, and components with teeth. The effect of improving the lubrication effect and the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

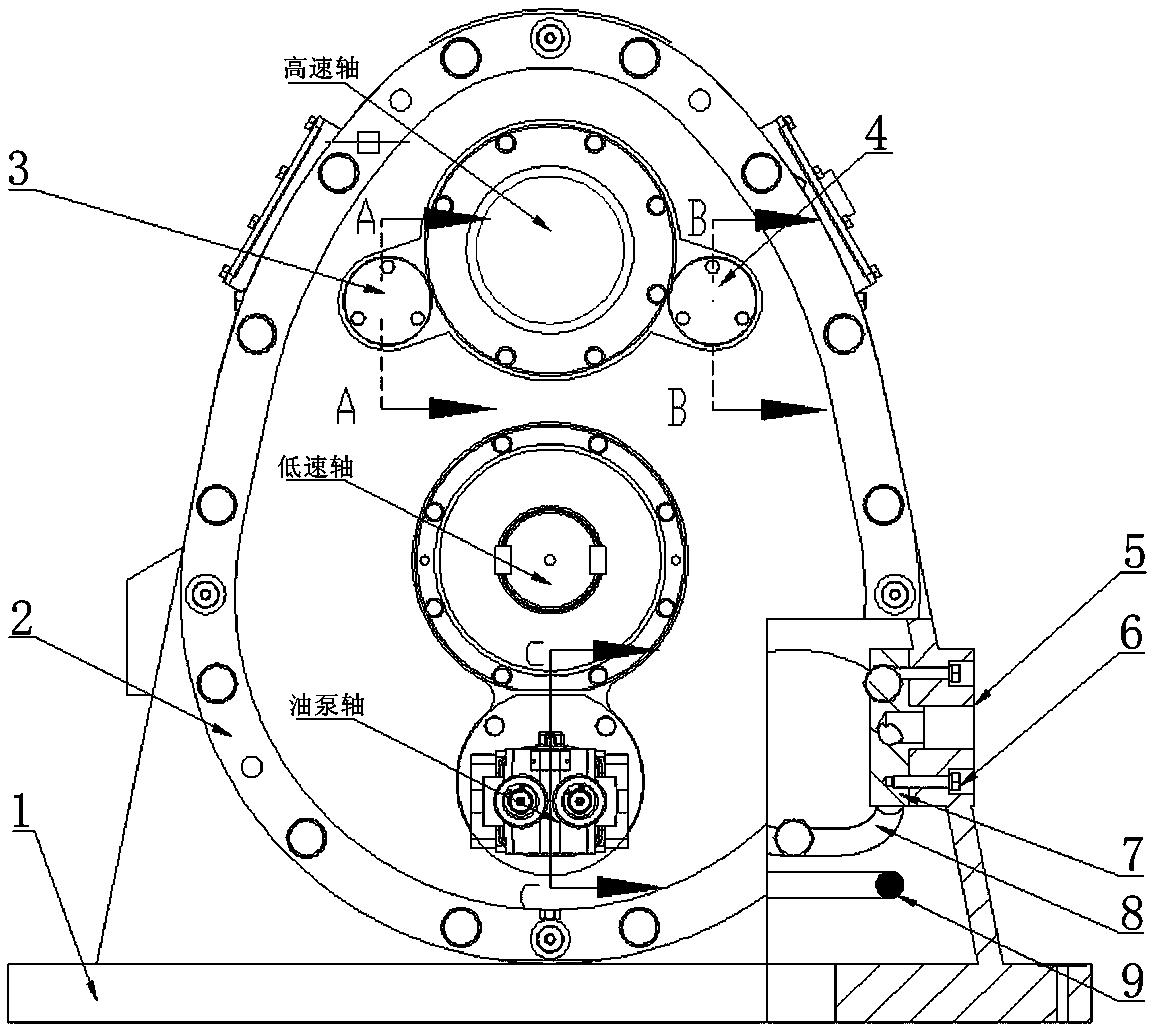

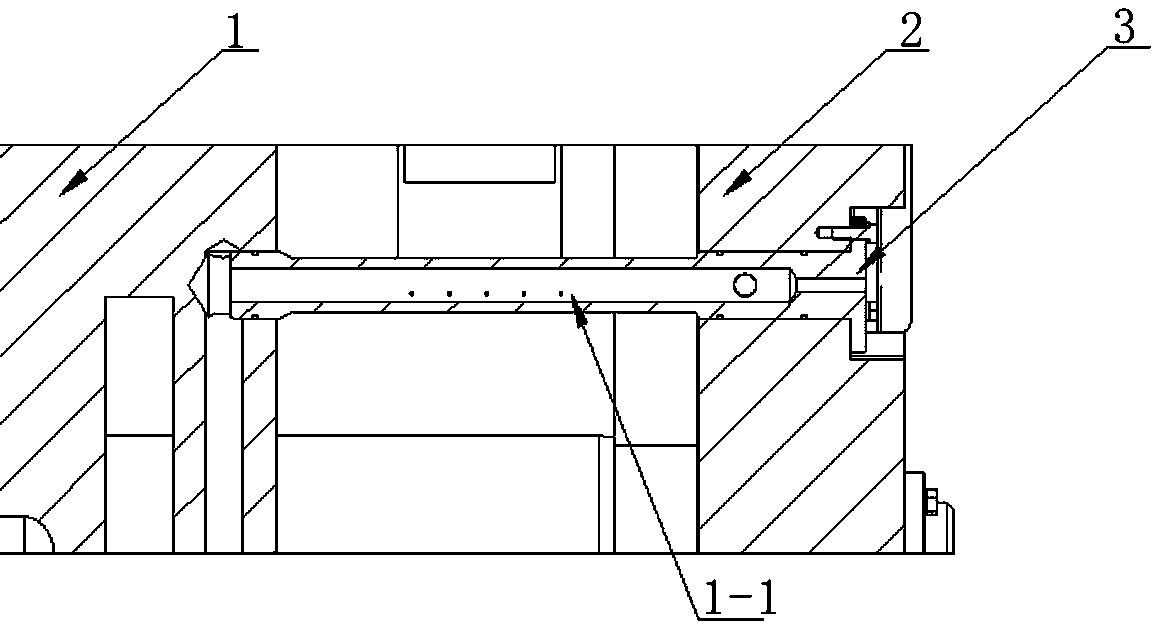

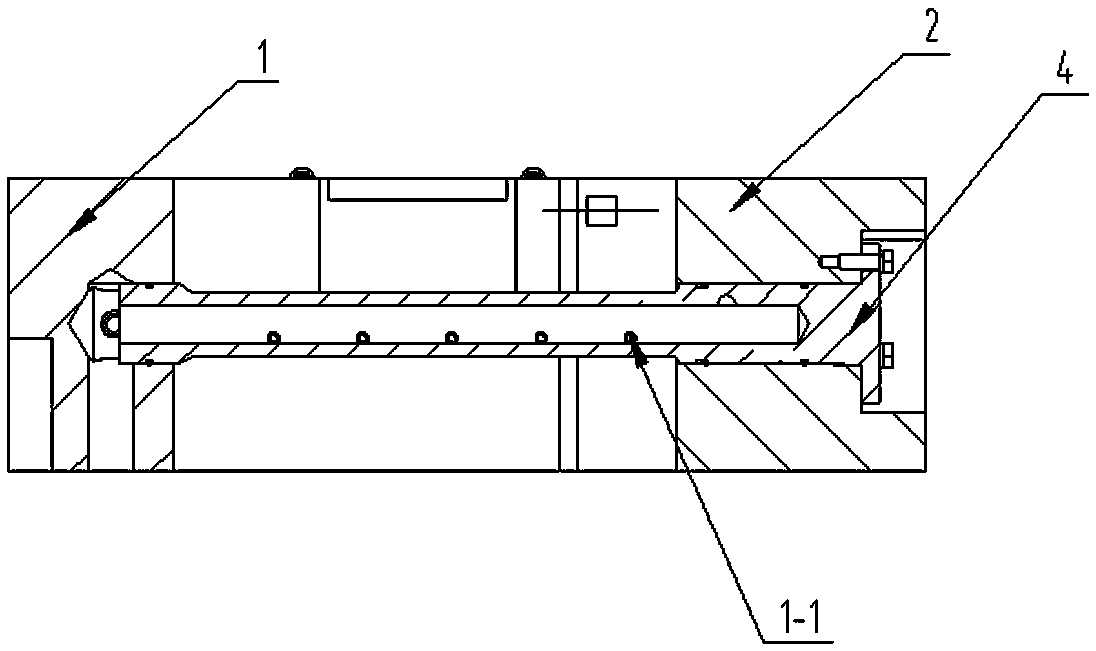

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-6 As shown, the lubricating system oil circuit structure of a vertical high-speed box according to the present invention mainly includes a box body 1, a box cover 2, an oil injection pipe, an oil inlet 5, a bolt 6, an oil distributor 7, a steel pipe, Plug 10 and pipe joint 11, the box body 1 is connected with the box cover 2 to form a front and rear sub-box structure of the gearbox with the high-speed bearing seat hole on the top and the low-speed bearing seat on the bottom; the fuel injection pipe is fixed on the box by bolts. The oil distributor 7 is installed inside the box through bolts 6 and connected to the oil inlet 5. The steel pipe and pipe joint 11 connect the oil distributor 7 with the inside of the box. The oil passage is connected.

[0019] As shown in the figure, the fuel injection pipe includes a first fuel injection pipe 3 and a second fuel inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com