Scraper blade type slag discharging device

A scraper type, straight scraper technology, applied in the direction of lighting and heating equipment, can solve the problem of waste slag not being discharged, and achieve the effect of increasing the concentration and improving the thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

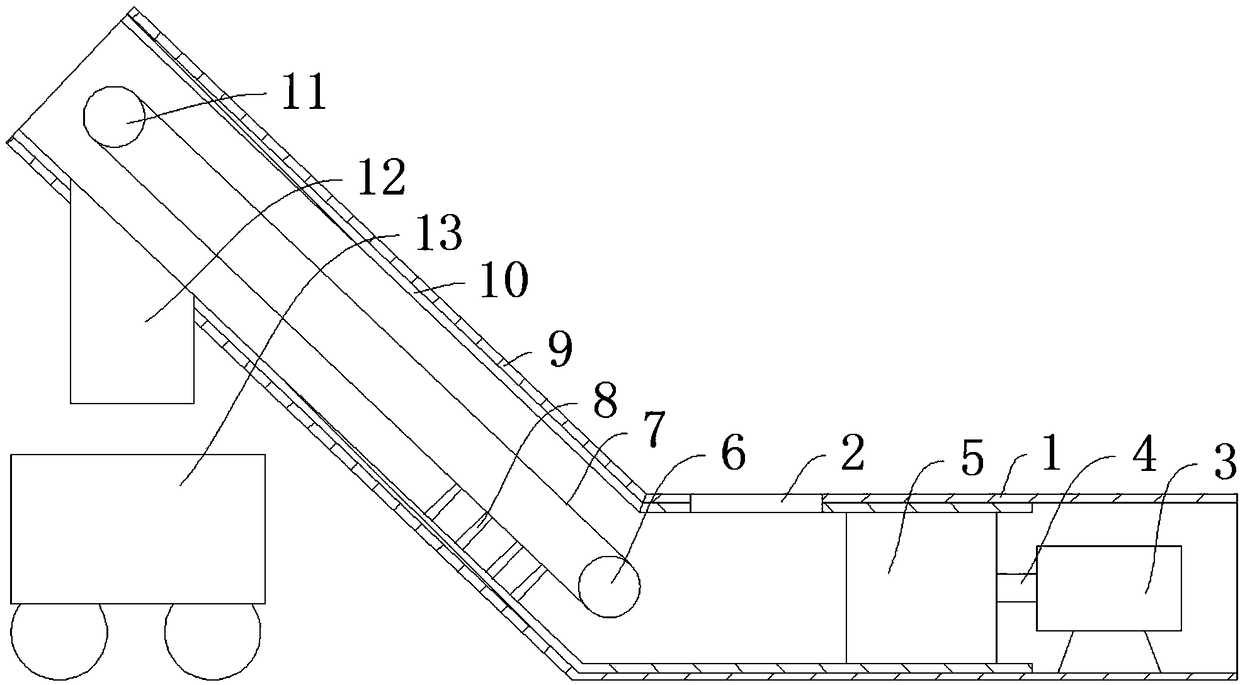

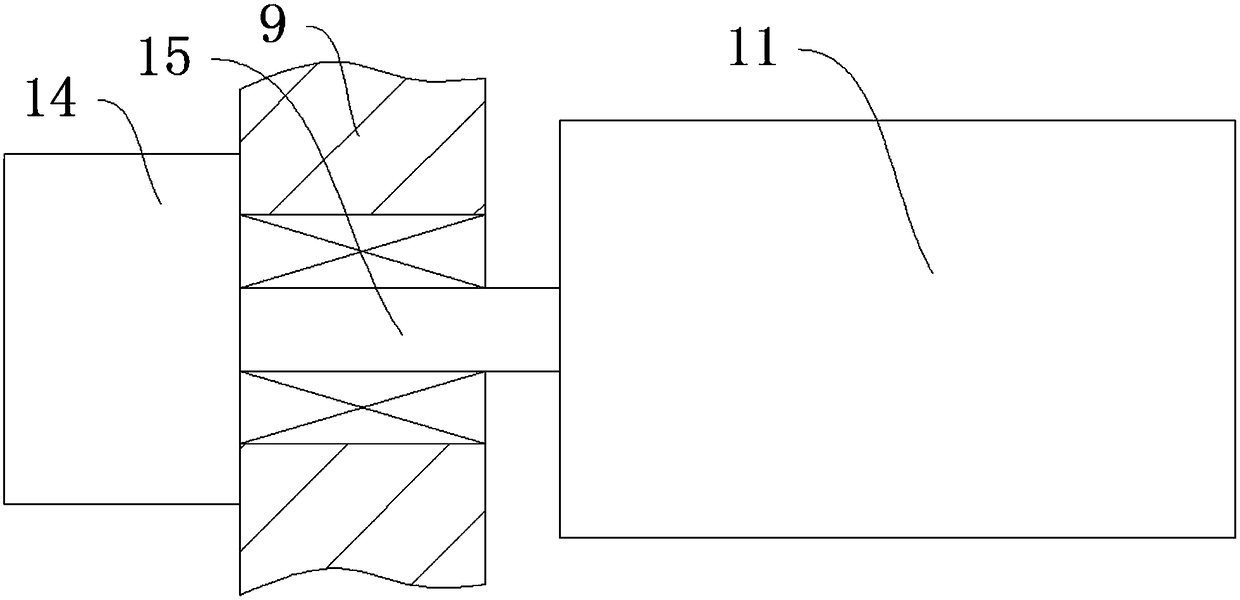

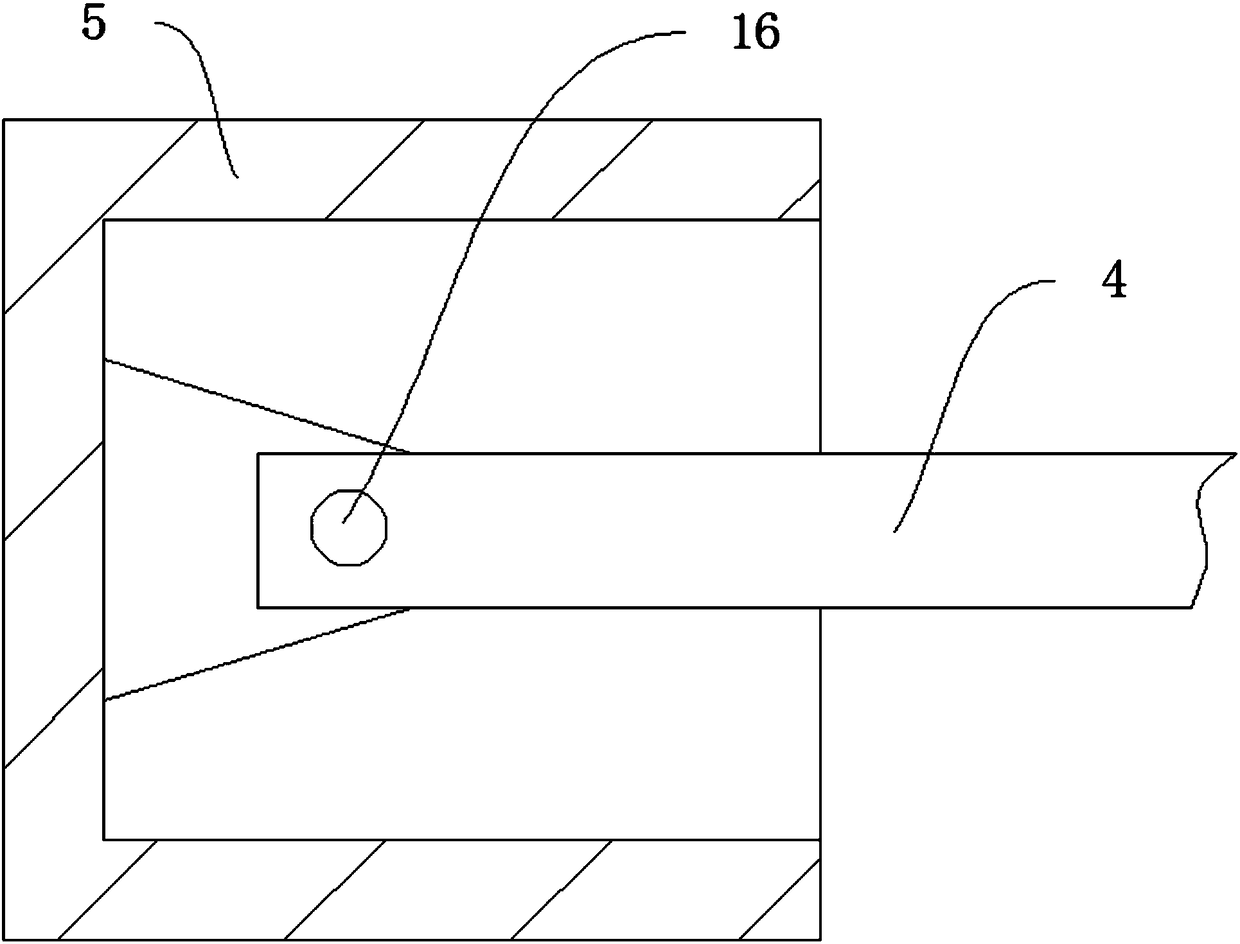

[0021] Such as Figure 1-Figure 3 As shown, a scraper-type slag discharge device includes a straight section 1, an oblique section 9, and a transport vehicle 13. A slag inlet 2 is arranged on the straight section 1, and the waste slag enters the passage of the straight section 1, and the straight section 1 is equipped with a hydraulic cylinder 3, which pushes the telescopic rod 4 to move. A telescopic rod 4 is arranged in front of the hydraulic cylinder 3 to drive the slag discharge head 5 to move. At the slag discharge head 5, a connecting pin 16 is arranged to connect the telescopic rod 4 and the slag discharge head 5. An oblique segment 9 is arranged in front of the straight segment 1, a passage for the waste slag to rise, and a motor 14 is arranged beside the oblique segment 9. Lift the power of the drive roller 11 to rotate, the motor 14 is provided with a drive shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap