Heat exchange system adopting cold source control method to realize intelligent constant temperature and control method of heat exchange system

A technology of heat exchange system and heating system, applied in the field of intelligent constant temperature heat exchange system, which can solve the problems of large temperature difference in the outlet temperature of warm boiled water, easy breeding of bacteria, occurrence of intestinal diseases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

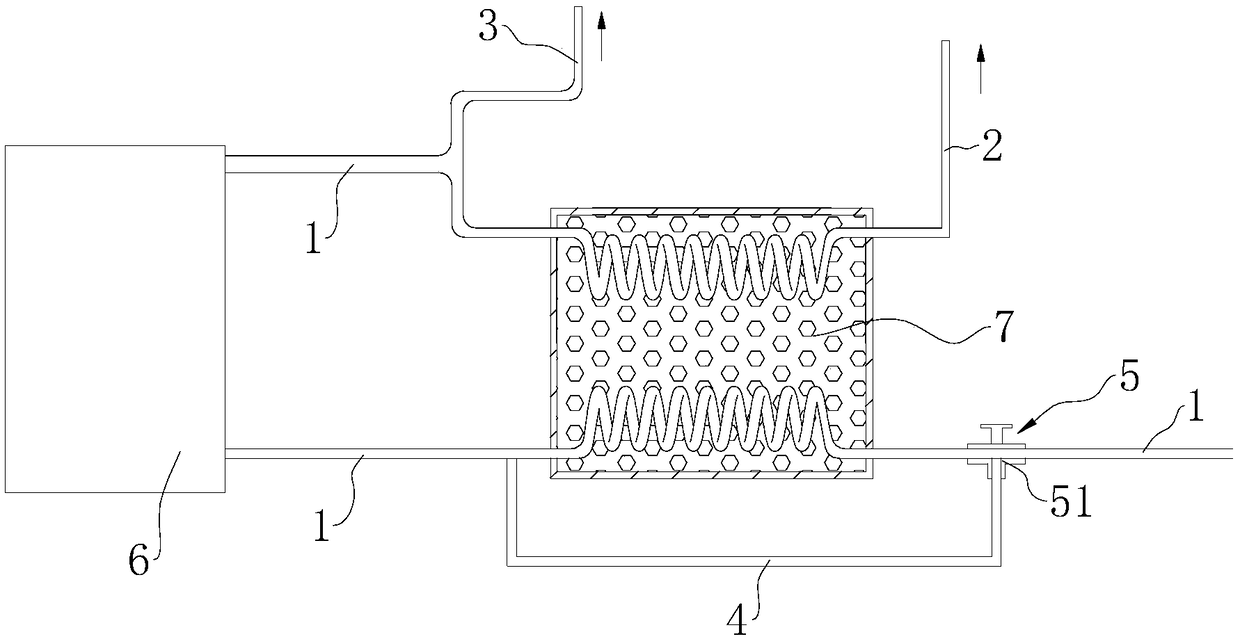

[0071] Embodiment 1: A heat exchange system that adopts cold source control method to realize intelligent constant temperature, such as figure 1 and 2 As shown, it includes a heating system 6, a heat exchange system 7, and a liquid inlet pipe 1 that passes through the heat exchange system 7 and the heating system 6 in turn and is used to introduce the liquid to be heated. One end of the liquid inlet pipe 1 extending out of the heating system 6 communicates with a The hot liquid pipe 3 and the warm liquid pipe 2, the warm liquid pipe 2 passes through the heat exchange system 7 and through the heat exchange system 7, the high-temperature liquid inside the warm liquid pipe 2 is heat-exchanged into a medium-temperature liquid, and the liquid to be heated passes through the liquid inlet pipe 1 in sequence. After the heat exchange system 7 and the heating system 6, the heating system 6 heats the liquid in the liquid inlet pipe 1 into a high-temperature liquid, and then enters the ho...

Embodiment 2

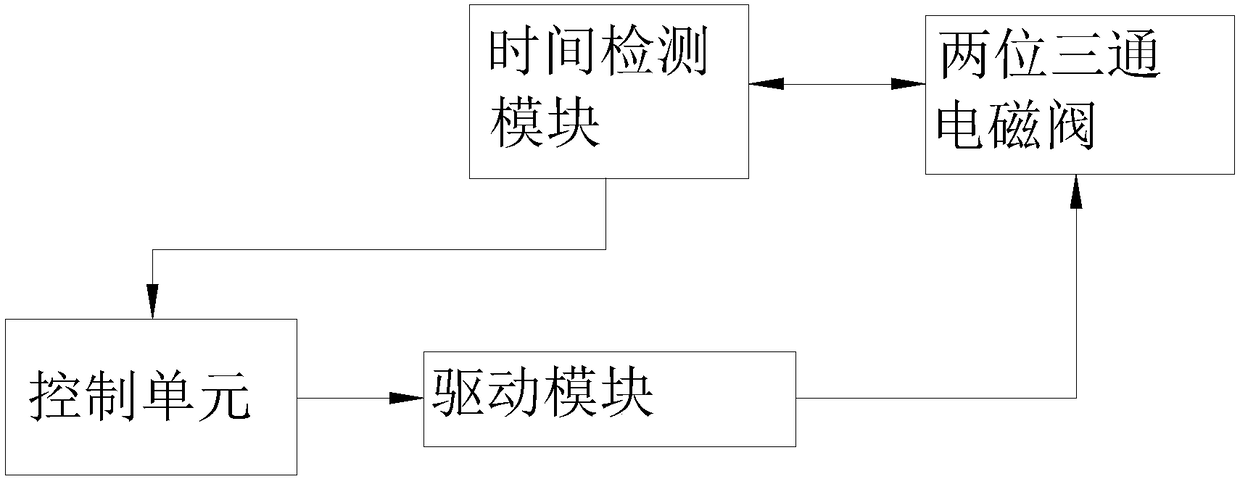

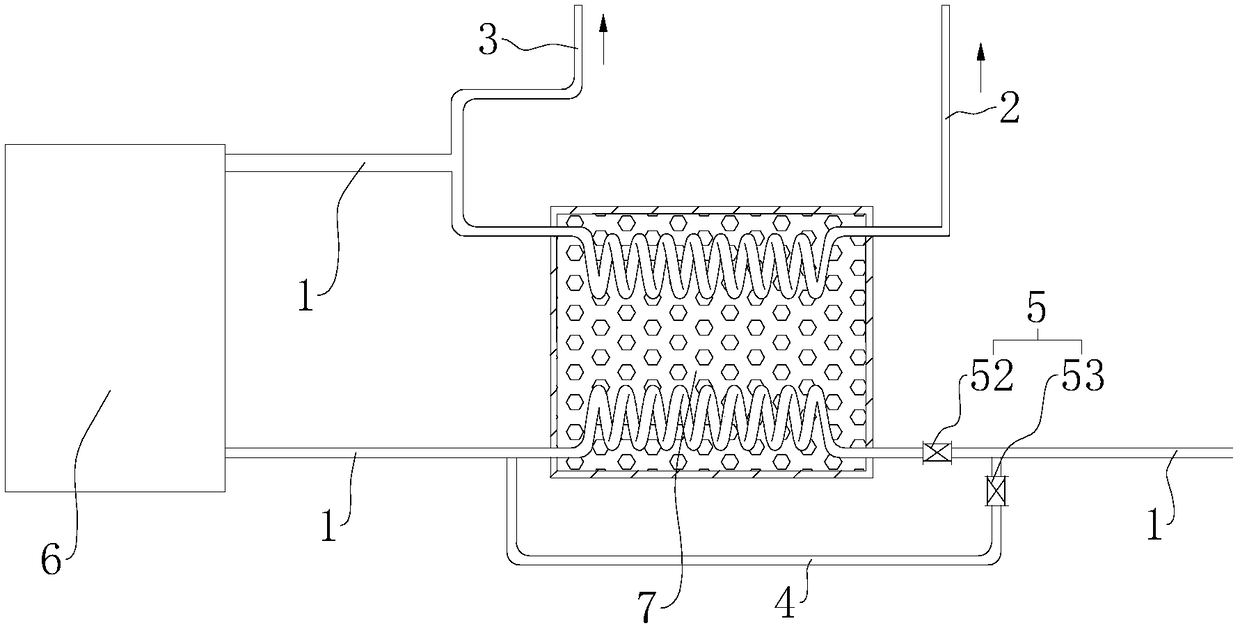

[0077] Embodiment 2: A heat exchange system that adopts cold source control method to realize intelligent constant temperature, such as image 3 and 4 As shown, the difference from Embodiment 1 is that the solenoid valve 5 includes a solenoid valve 1 52 and a solenoid valve 2 53, and the solenoid valve 1 52 is arranged on the liquid inlet pipe 1 between the heat exchange box and the temperature control branch pipe 4, The solenoid valve two 53 is arranged on the temperature control branch 4; the control system includes a drive module, a time detection module and a control unit, the control unit controls the working state of the drive module, and the drive module controls the opening and closing of the solenoid valve one 52 and the solenoid valve two 53, Then, the duration of opening and closing of the solenoid valve 2 53 is controlled by the time detection module; when the device is turned on, the solenoid valve 2 53 is opened to communicate with the temperature control branch ...

Embodiment 3

[0078] Embodiment 3: A heat exchange system that uses the cold source control method to realize intelligent constant temperature. The difference from Embodiment 1 is that, as Figure 5 and 6 As shown, the above solenoid valve 5 includes a proportional solenoid valve 1 54 and a proportional solenoid valve 2 55. The proportional solenoid valve 1 54 is arranged on the liquid inlet pipe 1 between the heat exchange box and the temperature control branch 4, and the proportional solenoid valve 2 55 is arranged on the The temperature control is in charge of 4; the control system includes a drive module, a time detection module and a control unit, the control unit controls the working state of the drive module, and the drive module controls the opening and closing of the proportional solenoid valve 1 54 and the proportional solenoid valve 2 55, and then passes the time detection The module controls the opening and closing duration of the proportional solenoid valve 2 55; when the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com