Spiral-plate-type heat exchanger with central heat-transfer strengthening effect

A technology of spiral heat exchange and heat transfer enhancement, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., and can solve problems such as low flow velocity, low heat exchange efficiency, and small heat transfer film coefficient , to achieve the effect of improving the ability to withstand external pressure, increasing the anti-fatigue ability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

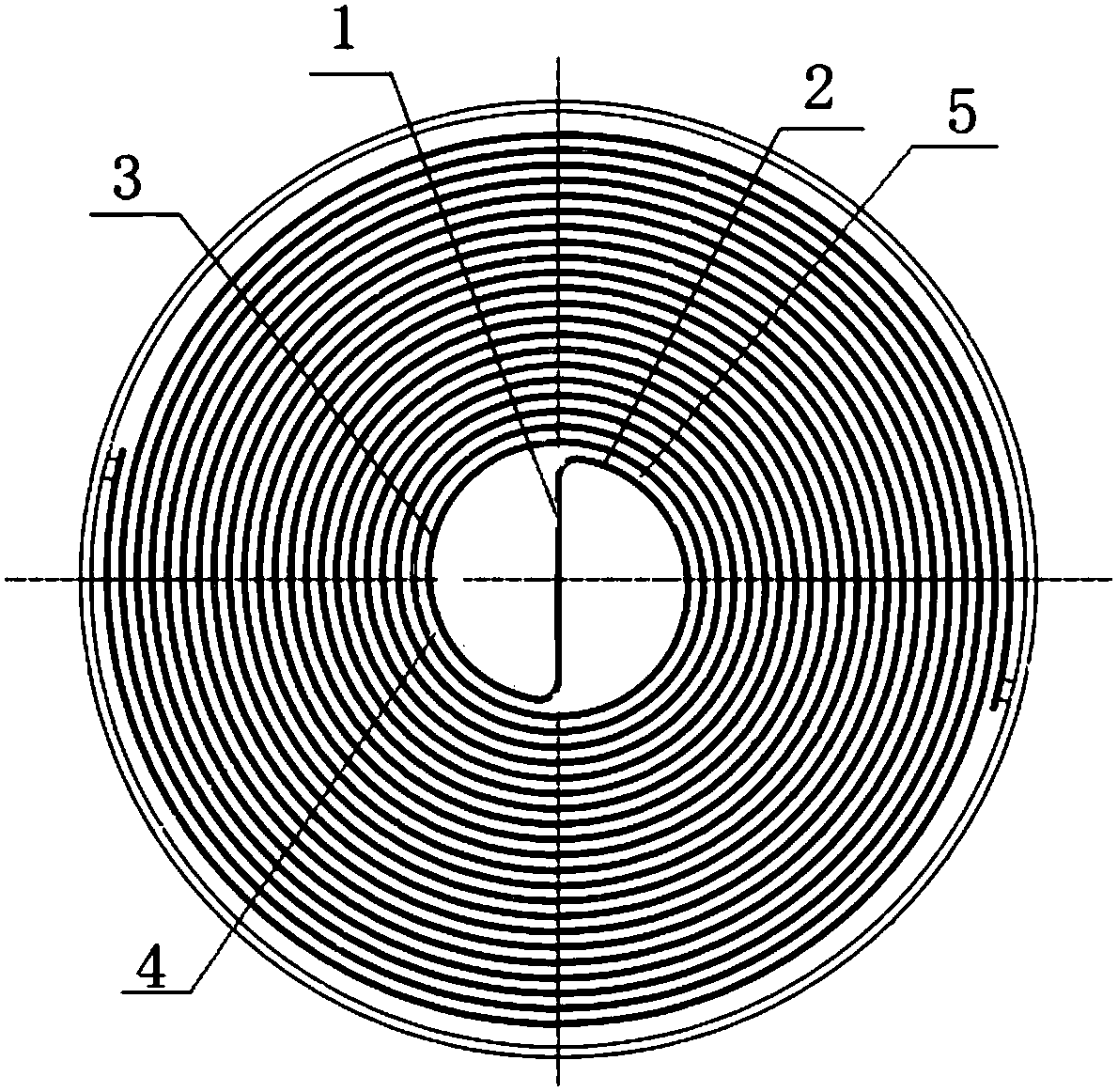

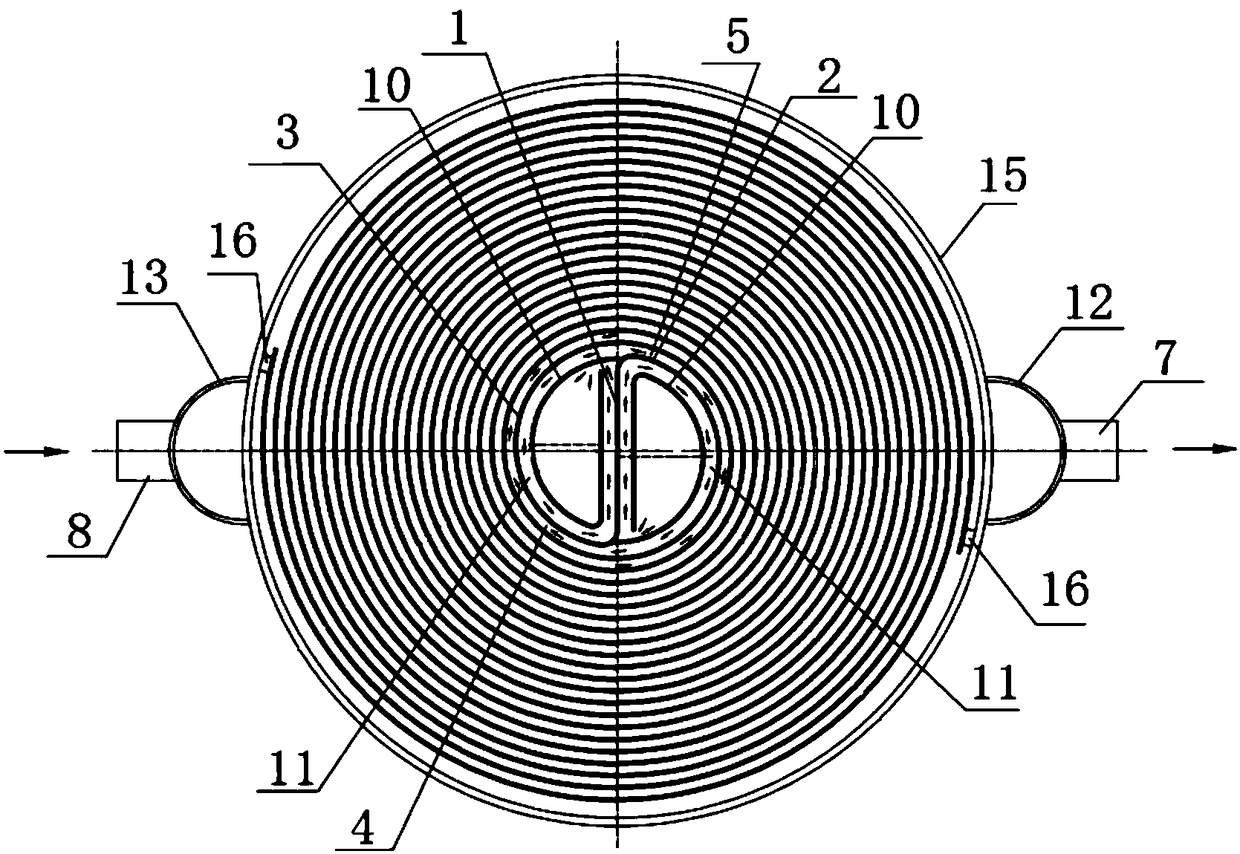

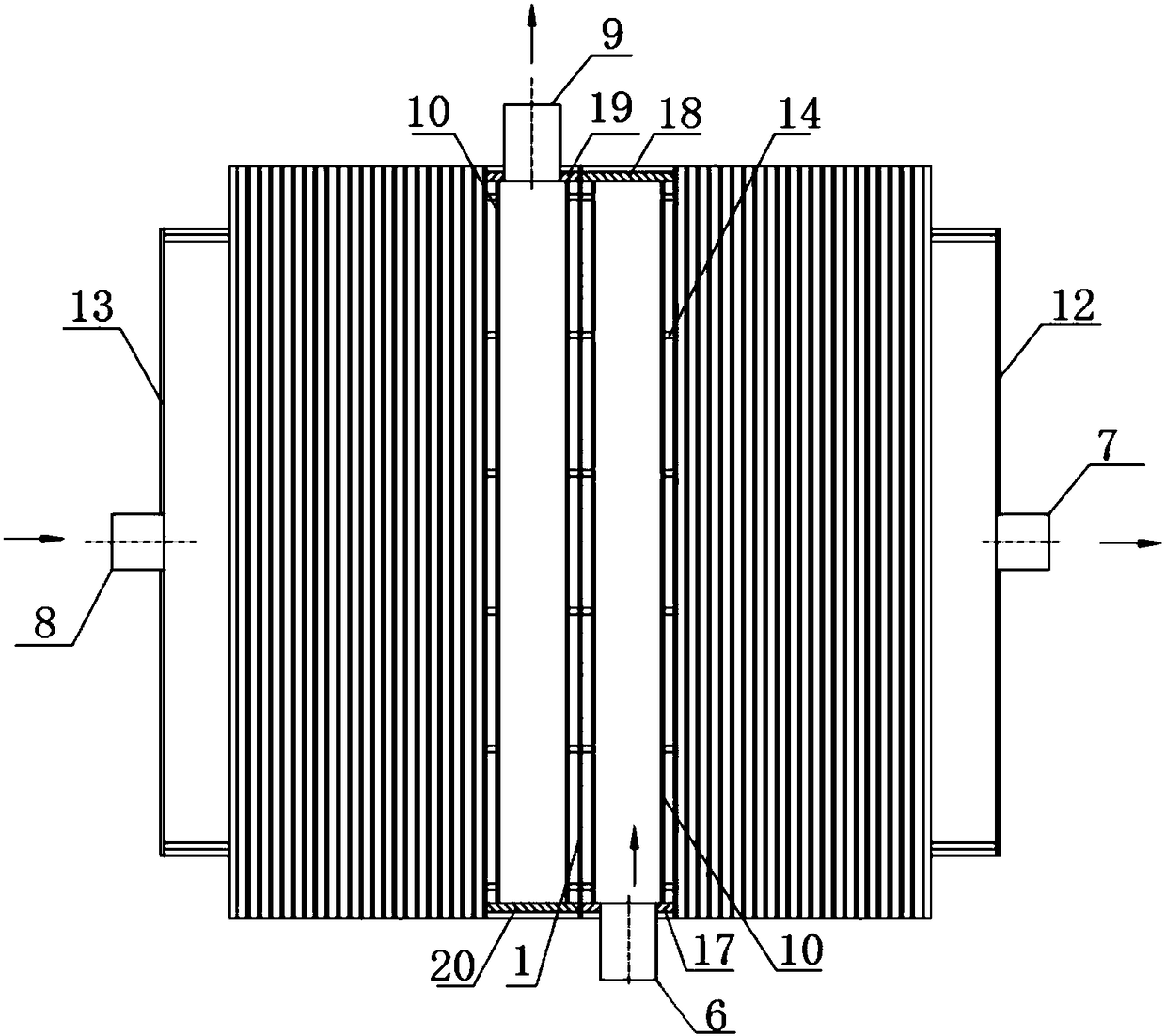

[0016] Such as figure 2 and image 3 The spiral plate heat exchanger with enhanced heat transfer in the center includes a central heat exchange plate 1, and the two sides of the central heat exchange plate 1 are respectively connected with the first spiral heat exchange plate 2 and the second spiral heat exchange plate 3 , the first spiral heat exchange plate 2 and the second spiral heat exchange plate 3 extend spirally and alternately toward the outer circle, forming a first spiral flow channel 4 for the first medium and a second spiral flow channel for the second medium The spiral flow channel 5, the ends and sides of the first spiral flow channel 4 and the second spiral flow channel 5 are independently sealed, and a circular cylinder 15 is sleeved on the outer circle of the spiral heat exchange plate, The cylinder body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com