High-efficiency and high-temperature ventilation and heat exchange device

A heat exchange device, high temperature technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of low strength of ventilation heat exchange plate, waste of ventilation pipe material, poor cooling effect, etc., and achieve heat insulation Good effect, shorter cooling time, faster cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

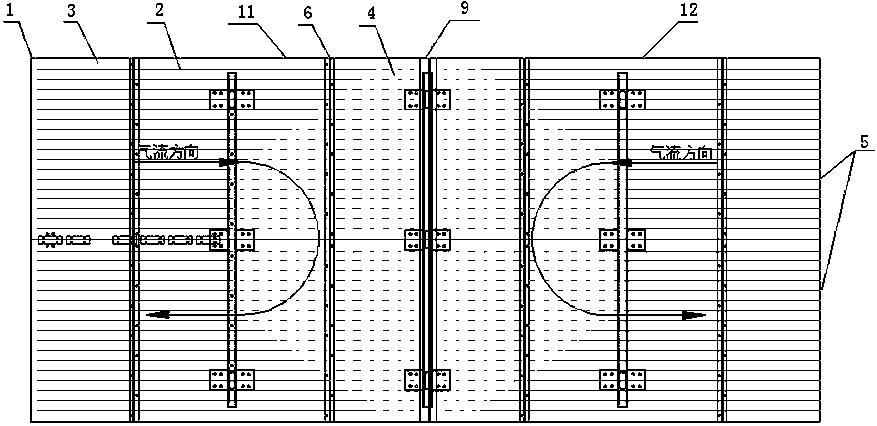

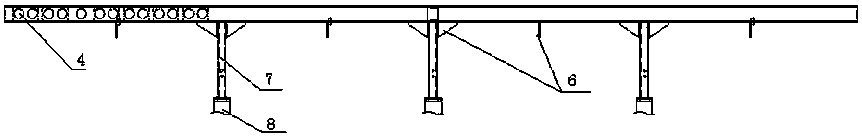

[0038] like figure 1 and figure 2 Shown: a high-efficiency high-temperature ventilation and heat exchange device, including a ventilation heat exchange plate 1, the ventilation heat exchange plate 1 is a hollow plate, and the middle part of the ventilation heat exchange plate 1 is provided with a longitudinally arranged partition plate 9 with gaps, and the ventilation heat exchange plate 1 The hot plate 1 is divided into two parts, the first independent plate body 11 and the second plate body 12. A plurality of partition ribs 2 are arranged in the cavities of the first plate body 11 and the second plate body 12, and the cavity is divided into multiple parts. There are three air ducts 3, and a plurality of ventilation holes 4 are provided on each partition rib 2 near the side of the partition plate 9, so that the gas flow direction in the first plate body 11 and the second plate body 12 is distributed in a U-shaped path.

[0039] Specifically, the ventilated heat exchange pla...

Embodiment 2

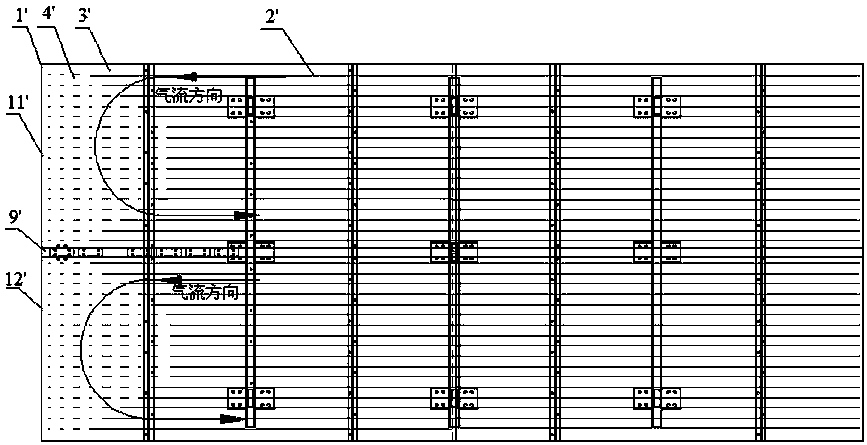

[0047] like image 3 As shown: the difference from Example 1 is: a high-efficiency high-temperature ventilation heat exchange device, including a ventilation heat exchange plate 1', the ventilation heat exchange plate 1' is a hollow plate, and the middle part of the ventilation heat exchange plate 1' is provided with a horizontal The partition plate 9' with a gap divides the ventilation heat exchange plate 1' into two parts: the first plate body 11' and the second plate body 12', and the space between the first plate body 11' and the second plate body 12' A plurality of partition ribs 2' parallel to the partition plate 9' are provided in the cavity, and the cavity is divided into a plurality of air ducts 3'. The left ends of the first plate body 11' and the second plate body 12' are closed, and each The left side of the strip dividing rib 2' is provided with a plurality of ventilation holes 4', nitrogen enters from the right end of the first plate body 11' or the second plate ...

Embodiment 3

[0052] like Figure 4 Shown: the difference with embodiment 2 is that: the left end of the first plate body 11 " is closed, and the left side of each partition rib in the first plate body 11 " is provided with a plurality of ventilation holes 4 ", and the nitrogen gas flows from the first plate body The right end of the body 11" enters, and the setting of the ventilation hole 4" makes the gas flow in the first plate body 11" distributed in a U-shaped path.

[0053] The right end of the second plate body 12 "is closed, and the right side of each partition rib in the second plate body 12" is provided with a plurality of ventilation holes 4", nitrogen enters from the left end of the second plate body 12", and the ventilation holes 4" The setting makes the gas flow in the second plate body 12" distributed in a U-shaped path.

[0054] That is, the air flow directions of the first plate body 11 ″ and the second plate body 12 ″ are opposite.

[0055] Other structures are with embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com