Outlet rotation measuring mechanism for turbine performance test

A technology for exporting rotation and turbine performance, applied in the field of aero-engines and gas turbines, can solve the problems of air leakage of the rotating measuring mechanism, stuck rotating mechanism, damaged parts, etc., and achieves the effect of simple structure, easy processing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be explained in detail below.

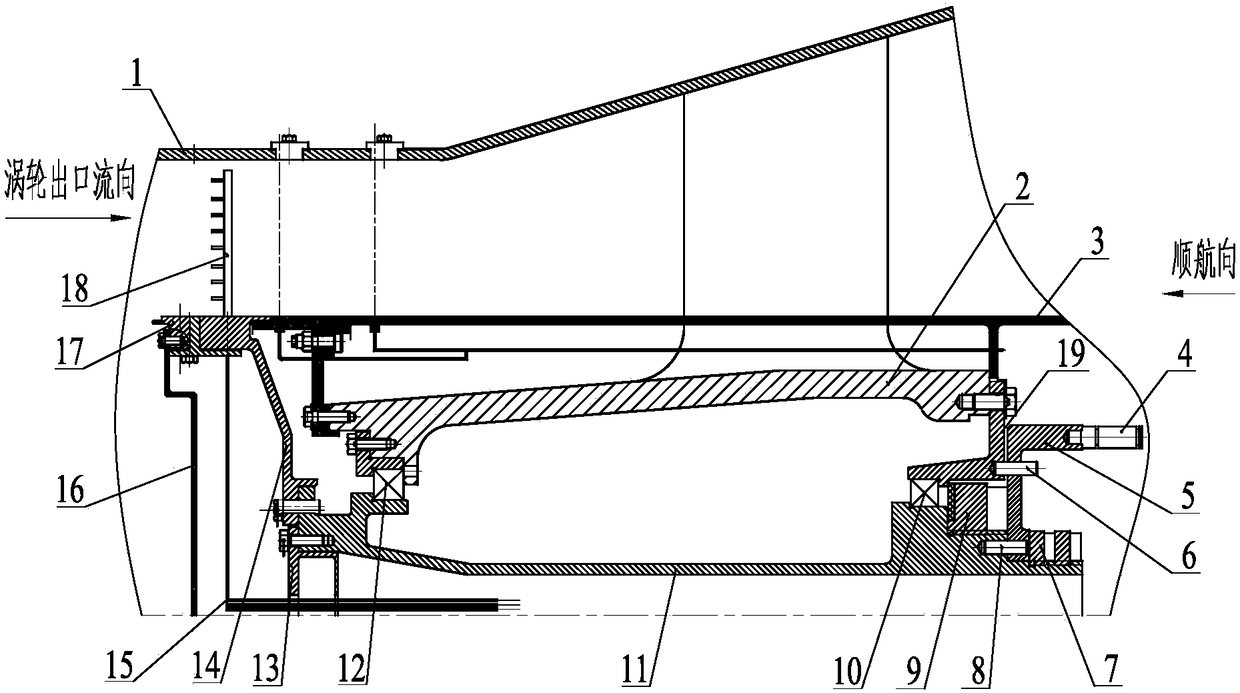

[0014] An outlet rotary measuring mechanism for turbine performance test is composed of an outer case (1), a load-bearing case (2), an inner case (3), a transmission crank (4), a force transmission plate (5), and a zero positioning Pin (6), compression threaded disc (7), power transmission pin (8), sealing block (9), rear bearing (10), torsion transmission shaft (11), front bearing (12), shaft center plug Block (13), rotating measuring disc (14), test pipeline (15), cavity sealing disc (16), flow channel sealing ring (17), rotating measuring probe (18), and bearing seat (19). Wherein, the outer casing (1) and the inner casing (3) are connected on the load-bearing casing (2), and the transmission crank (4) and the force transmission plate (5) are threadedly connected; the force transmission plate (5) ) and the torsion transmission shaft (11) are connected by the force transmission pin (8), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com