Calibration method of turntable rotation center of industrial CT system in offset scanning mode

A scanning mode and rotation center technology, applied in the field of rotation center calibration of industrial CT system turntables in offset scanning mode, can solve the problem of difficult to achieve rapid and accurate calibration of the projection position of the rotation center, and achieve shortened algorithm running time and strong anti-noise performance. , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0035] Before describing the method for calibrating the rotation center of the turntable of the industrial CT system in the offset scanning mode provided by the present invention, the standard fan beam scanning mode will be explained first.

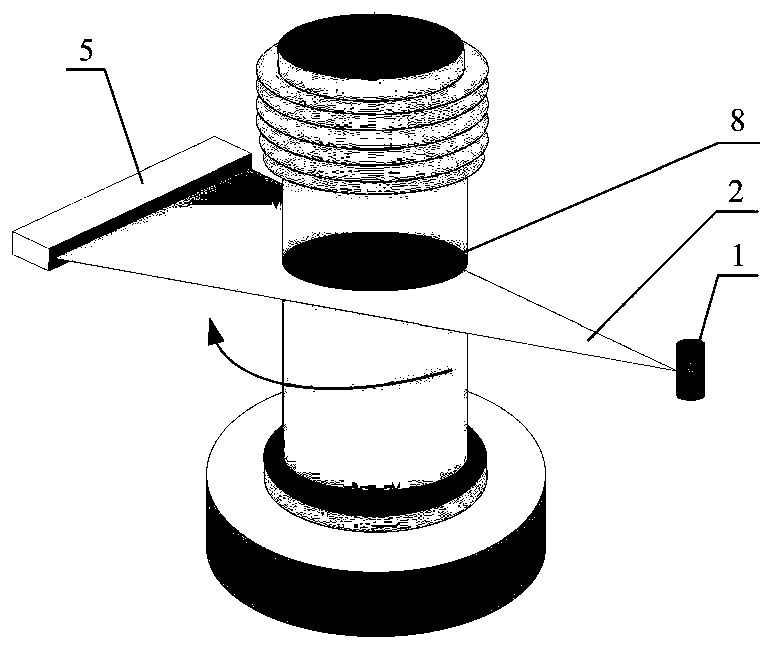

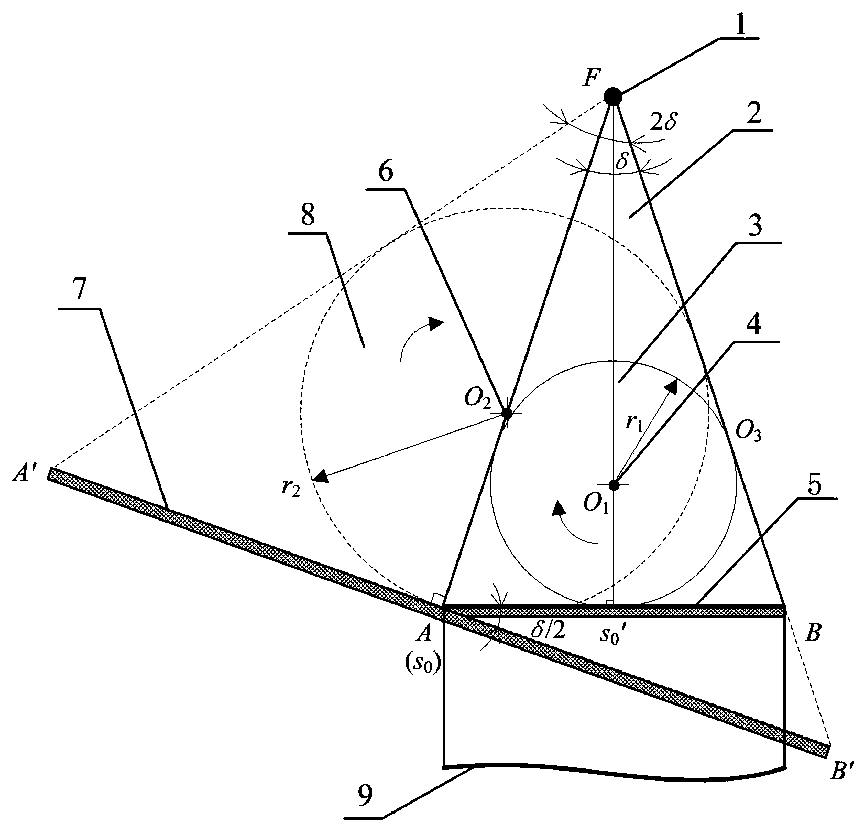

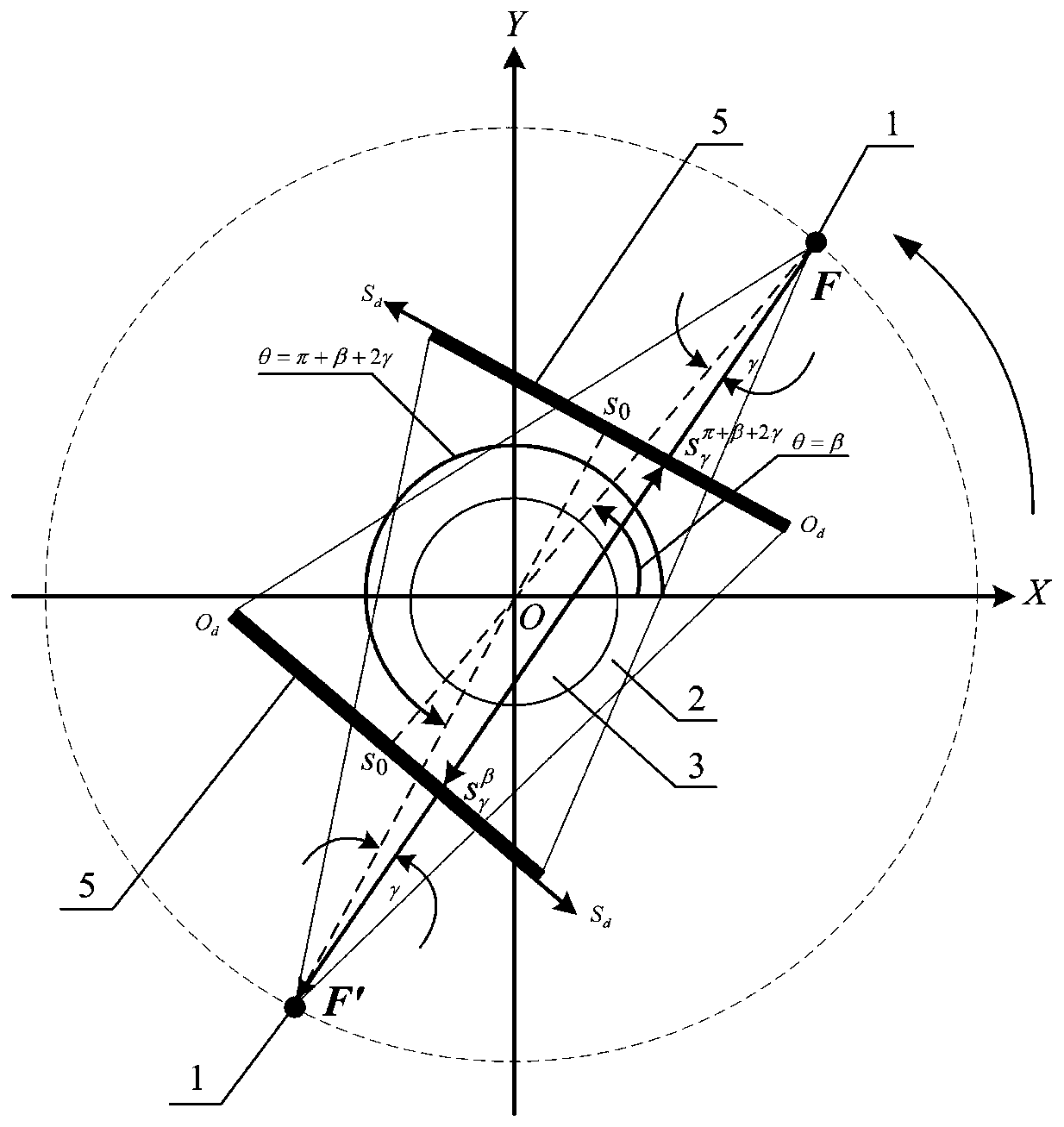

[0036] image 3 is the equivalent schematic diagram of the standard fan beam scanning mode in the prior art, such as image 3 As shown, during standard fan beam scanning, when the line connecting the radiation source 1 and the rotation center O is perpendicular to the detector 5, the radiation source 1 and the detector remain stationary, and the scanned slice rotates 360° around the rotation axis. This scanning process is equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com