Adhering method and liquid crystal display screen adhered by adhering method

A liquid crystal display and liquid crystal box technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of air bubbles, air bubbles cannot be discharged by rubber rollers, etc., to eliminate air bubbles, reduce rework rate, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

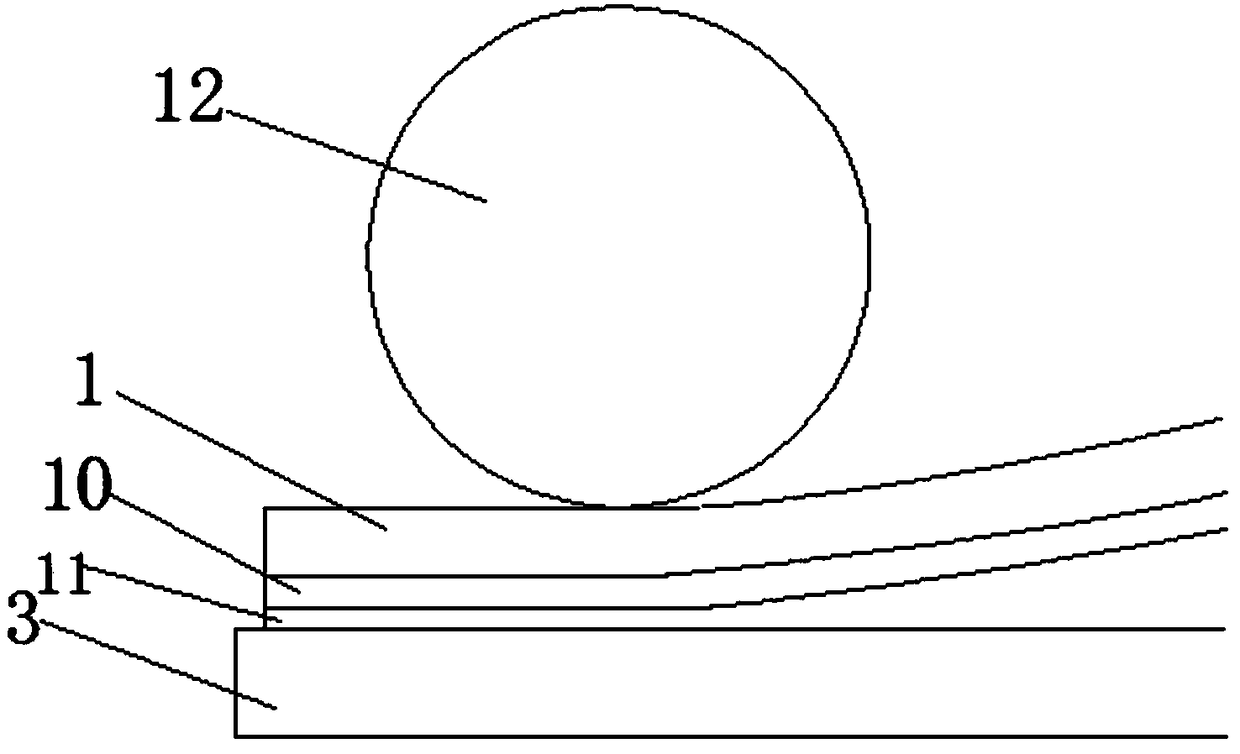

[0027] like figure 1 As shown, a fitting method, including

[0028] S1: Optical adhesive 10 is adhered to the lower surface of the polarizer, and the bonding environment is controlled to be in a dust-free state, and the ambient temperature is controlled between 18° and 26°; in this embodiment, the ambient temperature is controlled at 22°, Under this environment, the storage effect of the optical glue 10 is the best; the optical glue 10 is set as a solid OCA optical glue;

[0029] S2: Control the downward pressure of the rubber roller 12, and its downward pressure is controlled between 0.1 and 0.2 MPa; in this embodiment, the pressure of the rubber roller 12 is controlled to be 0.1 MPa, and the downward pressure of the rubber roller 12 is relatively small to ensure rolling. There will be no indentation on the polarizer during the process; when the pressure is small, there is a certain gap between the polarizer and the glass substrate, and there will be air bubbles;

[0030] S...

Embodiment 2

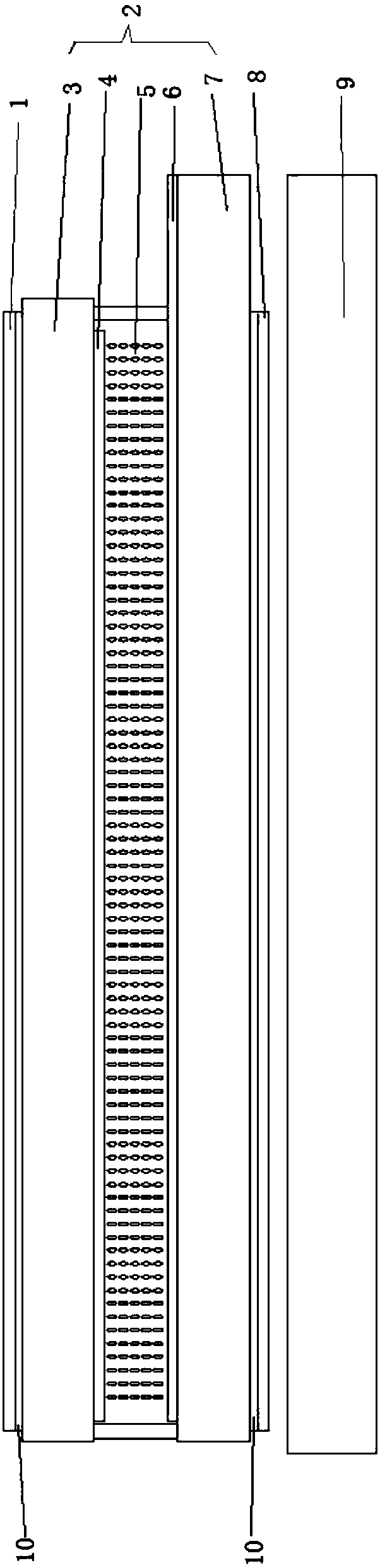

[0036] like figure 2 As shown, a bonded liquid crystal display screen, the liquid crystal display screen bonded by the bonding method in Embodiment 1, includes a surface polarizer 1, a liquid crystal cell 2, a bottom polarizer 8 and a backlight plate 9, the surface The polarizer 1 is arranged above the liquid crystal cell 2, the backlight plate 9 is arranged below the liquid crystal cell 2, and a bottom polarizer 8 is arranged between the backlight plate 9 and the liquid crystal cell 2; the liquid crystal cell 2 includes a surface glass substrate 3 , a liquid crystal layer 5 and a bottom glass substrate 7; the surface polarizer 1 is attached above the surface glass substrate 3 by the bonding method, and a bottom is attached on the lower surface of the bottom glass substrate 7 by the bonding method. Polarizer 8: The lamination method in Example 1 can reduce the air bubbles between the polarizer and the glass substrate. At the same time, OCA optical glue and OCR optical glue ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com