Micro-extraction method based on phase transition properties of temperature-sensitive polymers

A temperature-sensitive polymer and polymer technology, applied in the field of micro-extraction, can solve the problem of low extraction rate and achieve high extraction rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

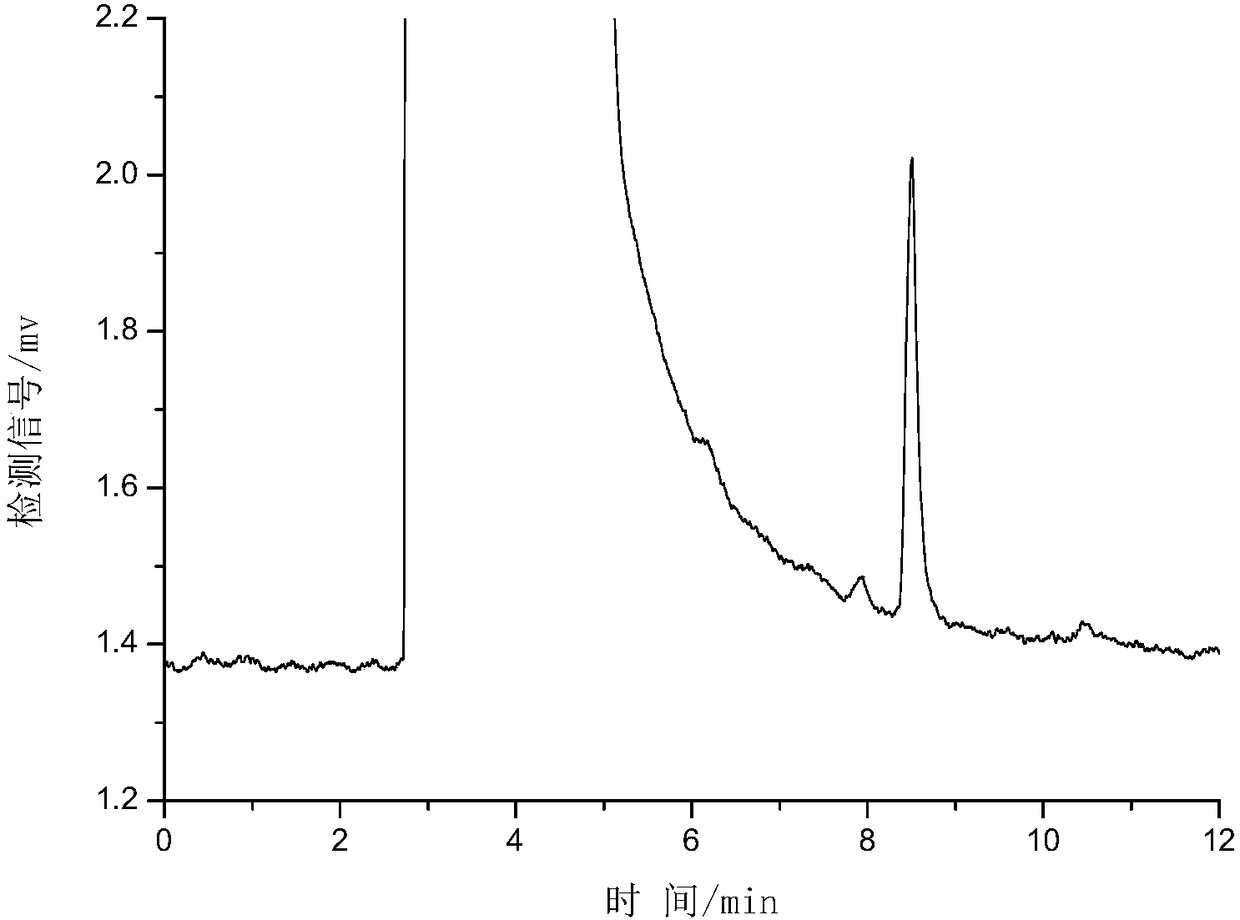

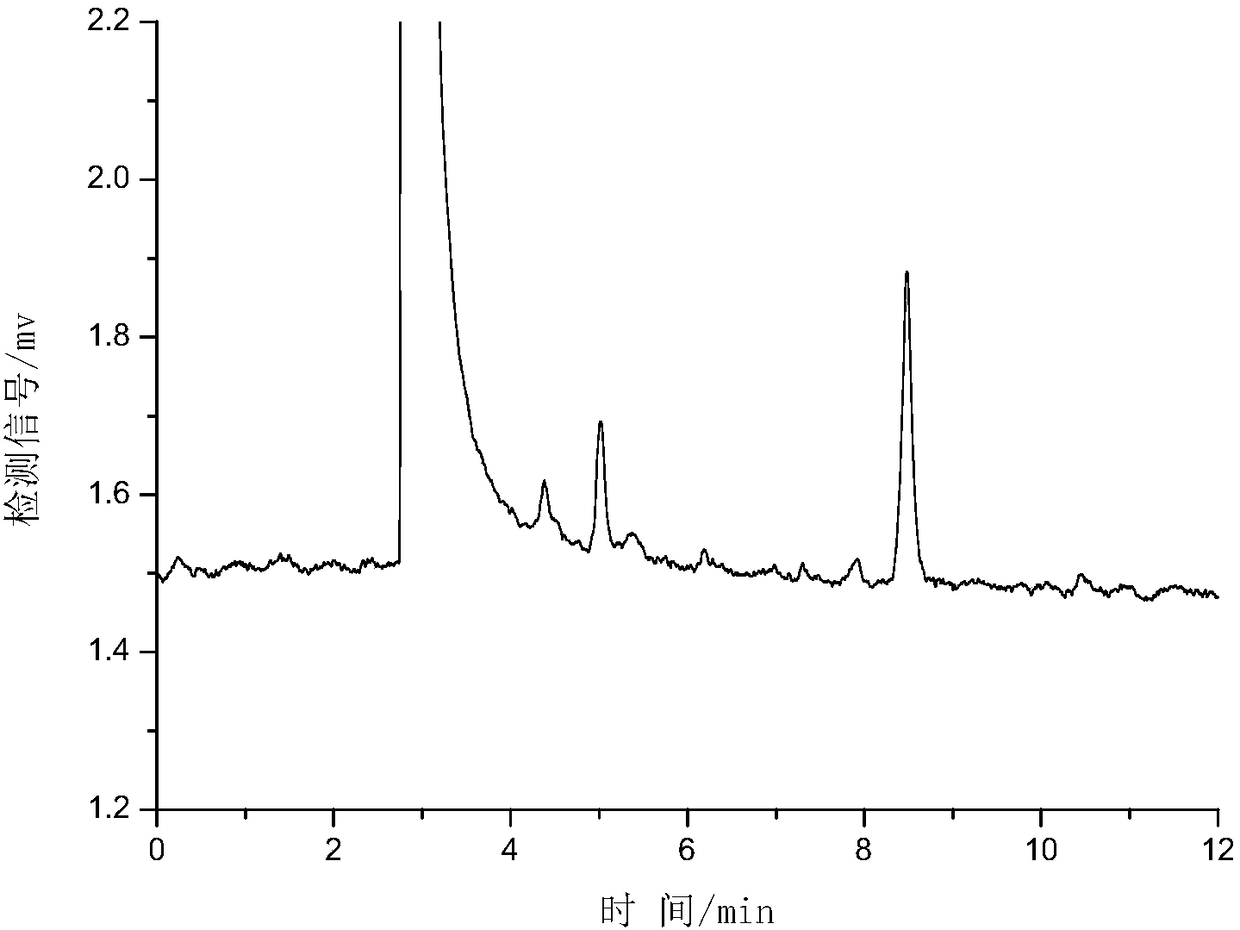

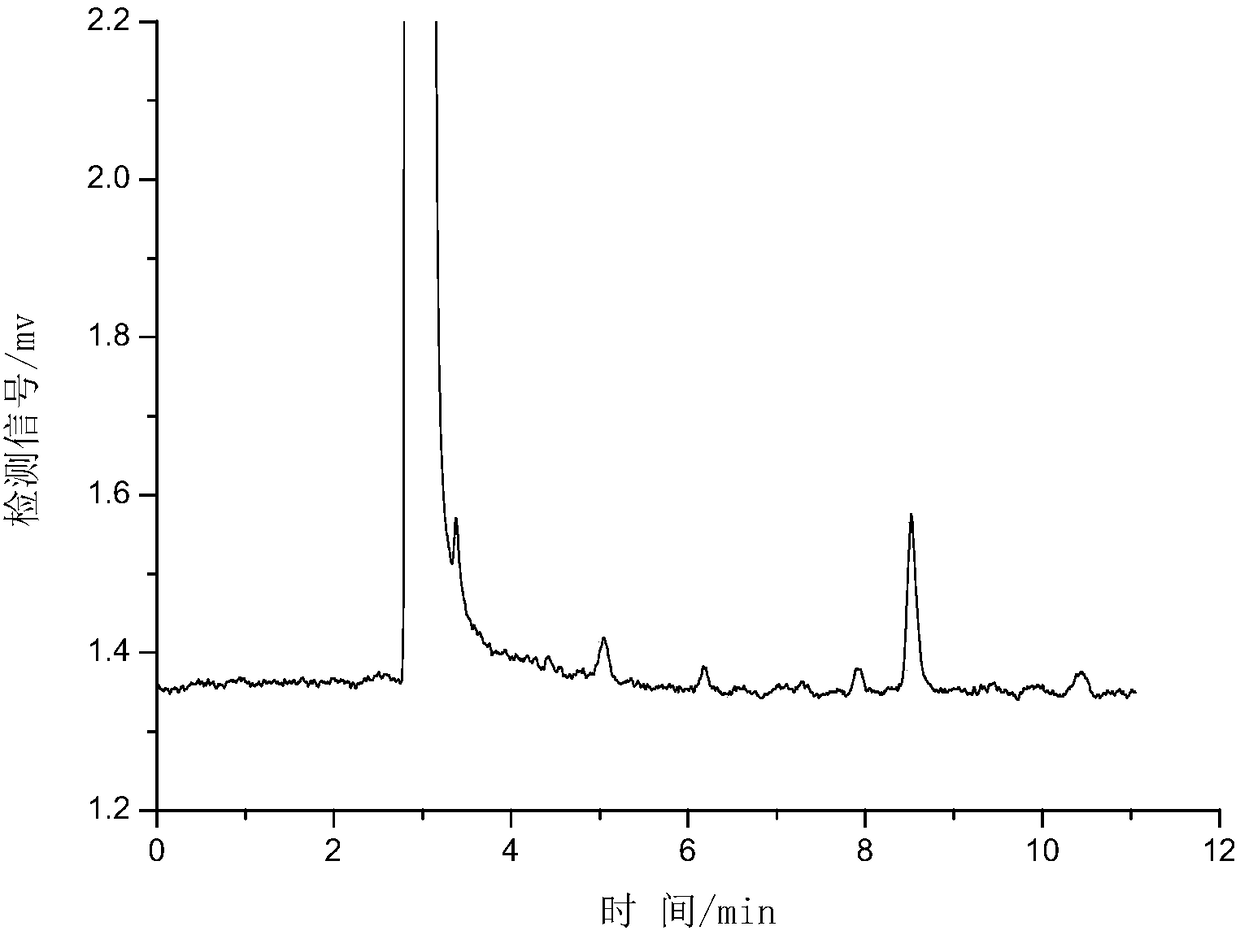

Image

Examples

Embodiment

[0020] A kind of micro-extraction method based on temperature-sensitive polymer phase transition property, comprises the steps:

[0021] 1. Add 20mL of water sample containing dibutyl phthalate and 10mg of β-CD-PNIPAM to the colorimetric tube to form a mixed aqueous solution; the concentration of dibutyl phthalate in the water sample is 1ug / mL , the concentration of β-CD-PNIPAM in the mixed aqueous solution is greater than the concentration of dibutyl phthalate;

[0022] 2. Put the colorimetric tube into a 40°C water bath. Since β-CD-PNIPAM is a temperature-sensitive polymer, the solution turns from clear to cloudy after heating. Add 2g of sodium sulfate to make the cloudy liquid form a solid-phase substance and a liquid Two phases, the solid phase material is collected by centrifugation, and the solid phase material is the solid phase material formed after the polymer β-CD-PNIPAM absorbs the organic pollutant dibutyl phthalate.

[0023] 3. Add 200 uL of ethyl acetate to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com