Compound extractant for content detection of soluble substance in elastomer modified asphalt waterproof membrane and detection method

A technology of asphalt waterproof membrane and composite extractant, which is applied in the field of composite extractant and elastomer modified asphalt waterproof membrane soluble content detection, which can solve the anesthesia effect of the central nervous system, trigeminal nerve damage, and long extraction time etc. to achieve the effects of low temperature, shortened extraction time and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

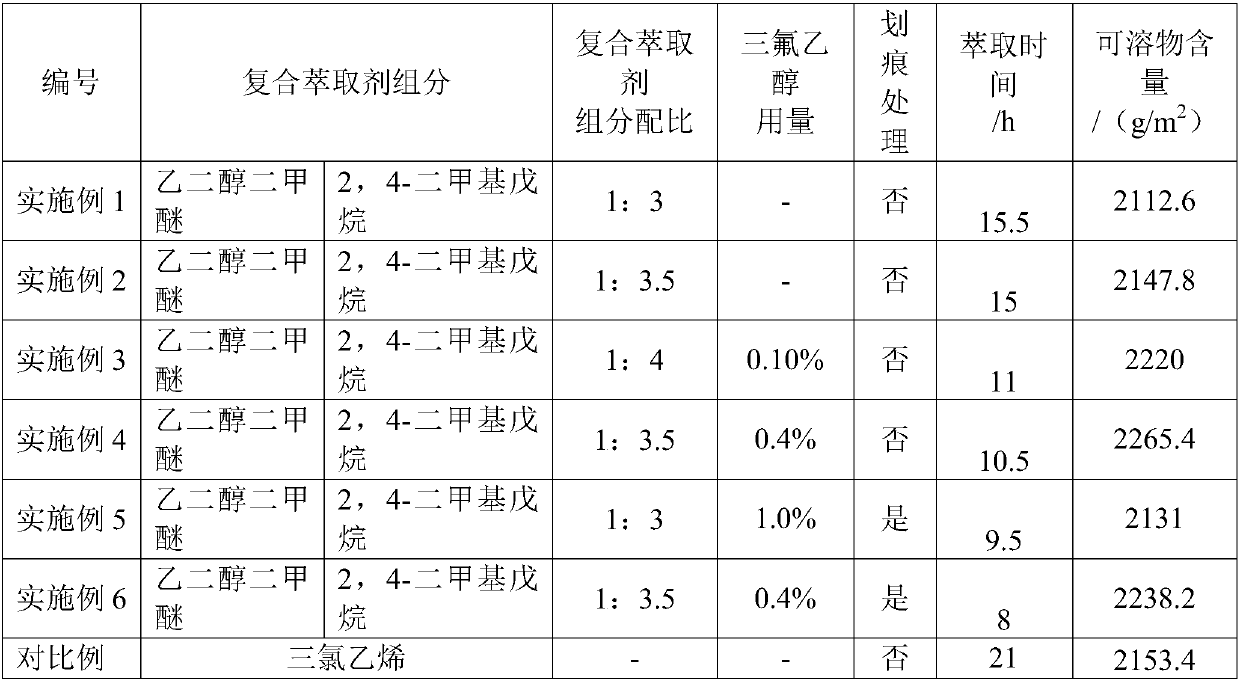

Embodiment 1

[0025] (1) Preparation of composite extractant: mix according to the mass ratio of ethylene glycol dimethyl ether and 2,4-dimethylpentane of 1:3, and prepare a composite extractant.

[0026] (2) Specimen preparation: cut the coiled material, and cut 3 square specimens with a size of (100±1)mm×(100±1) on the coiled material at least 100mm from the edge;

[0027] Before the test, the specimen should be placed for at least 20 hours under the conditions of (23±2)°C and a relative temperature of 30% to 70%.

[0028] (3) Wrap the test piece with dry filter paper, tie it up with a thread, and weigh its mass as M 1 ;Put the wrapped test piece into the extractor, the amount of compound extractant is 1 / 2~2 / 3 of the capacity of the flask, heat and extract in a water bath, and extract until the refluxing compound extractant turns light for the first time, be careful Take out the filter paper bag without breaking it, and place it in the air for more than 30 minutes to volatilize the compo...

Embodiment 2

[0031] Example 2 and Example 1 have the same preparation and extraction method of the test piece, the difference is: when preparing the composite extractant, the mass ratio of ethylene glycol dimethyl ether to 2,4-dimethylpentane is 1:3.5. Mix and prepare compound extractant. The test results are shown in Table 1.

Embodiment 3

[0033] Example 3 is the same as Example 1 in the preparation and extraction of the test piece, the difference is: when preparing the composite extractant, the mass ratio of ethylene glycol dimethyl ether to 2,4-dimethylpentane is 1:4. Mix and add 0.1% trifluoroethanol to the total mass of ethylene glycol dimethyl ether and 2,4-dimethylpentane to prepare a composite extractant. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com