Bucket wheel reclaimer applied to bulk cargo blending operation

A reclaimer and bucket wheel technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low mixing accuracy of bulk cargo, high overall cost, affecting promotion and use, etc., and achieve an effective mixing operation mode, The effect of broad application prospects and accurate and controllable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

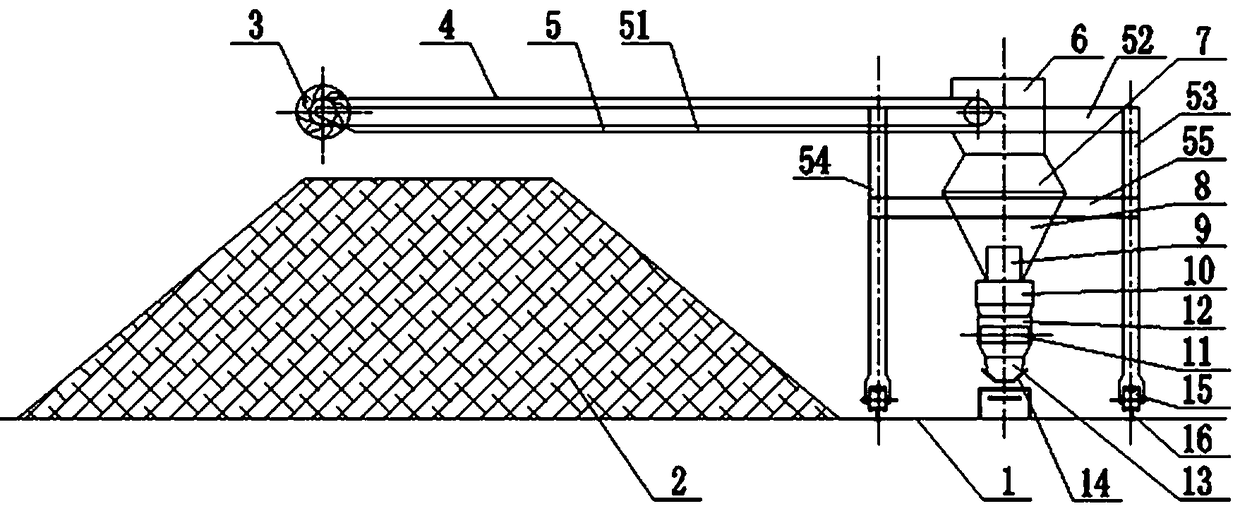

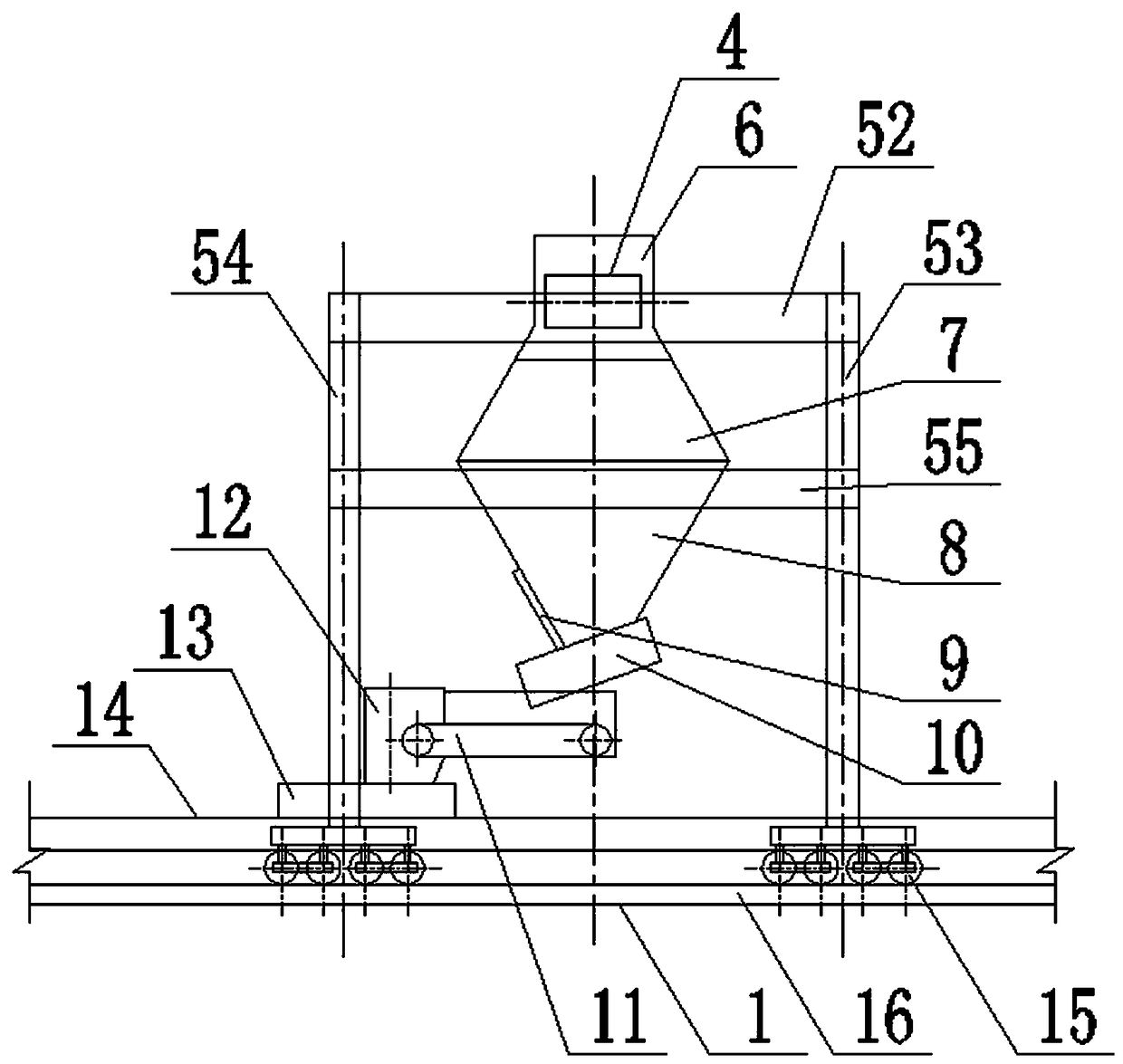

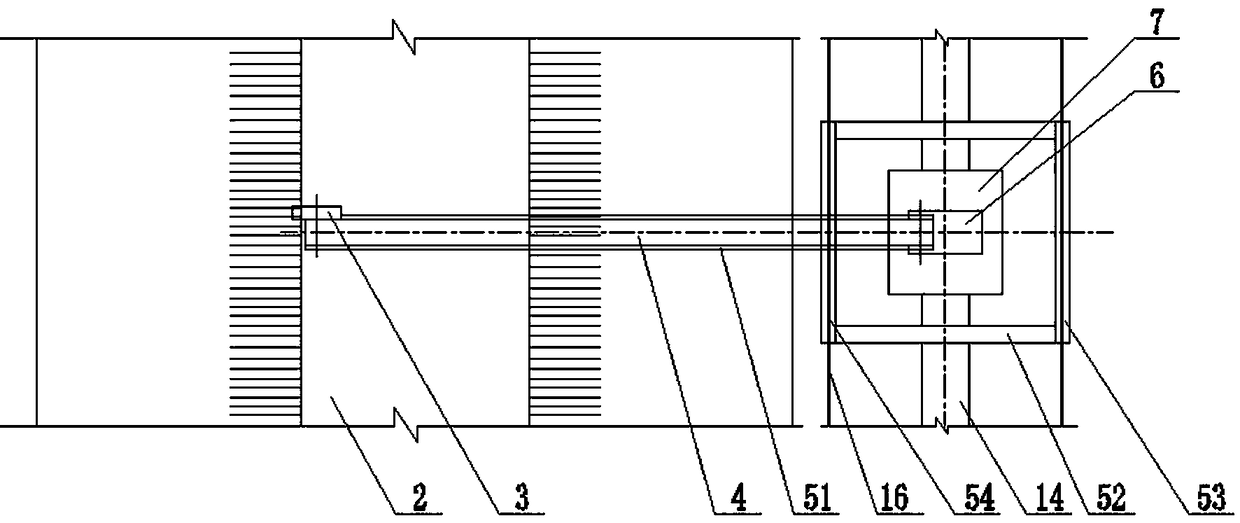

[0025] Such as figure 1 , figure 2 and image 3 As shown, a bucket wheel reclaimer used in bulk cargo mixing operations includes a bucket wheel 3, a cantilever belt conveyor 4, a steel structure 5, a first head funnel 6, a buffer bucket, an electric gate 9, and a vibrating feeding machine 10, weighing feeder 11, second head funnel 12 and material guide trough 13, traveling mechanism 15 and steel rail 16; the steel structure 5 includes a boom 51, an upper beam 52, a rear door frame 53, and a front door frame 54 and lower cross beam 55; described front door frame 54 and rear door frame 53 are arranged in parallel, upper cross beam 52 and lower cross beam 55 are arranged between front door frame 54 and rear door frame 53, and the top of front door frame 54 is provided with arm frame 51, arm frame 51 Located above the bulk cargo 2 stored on the ground 1; the upper beam 52 is located on the top of the front door frame 54 and the rear door frame 53, and the lower beam 55 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com